- Overview

- Product Description

- Product Parameters

- Product Features

- Our Services

- Related Products

- Company Profile

- Packaging & Shipping

Basic Info.

Product Description

High Effective Light Impurity Separator Slag Separator For Paper And Pulp

Mingyi can produce various of papermaking equipment, gelatin equipment and aerogel equipment, including hydraulic pulper, pressure screen, gas liquid separator, refiner, belt conveyor, gelatin votator, band dryer, multi-effect evaporator, etc.

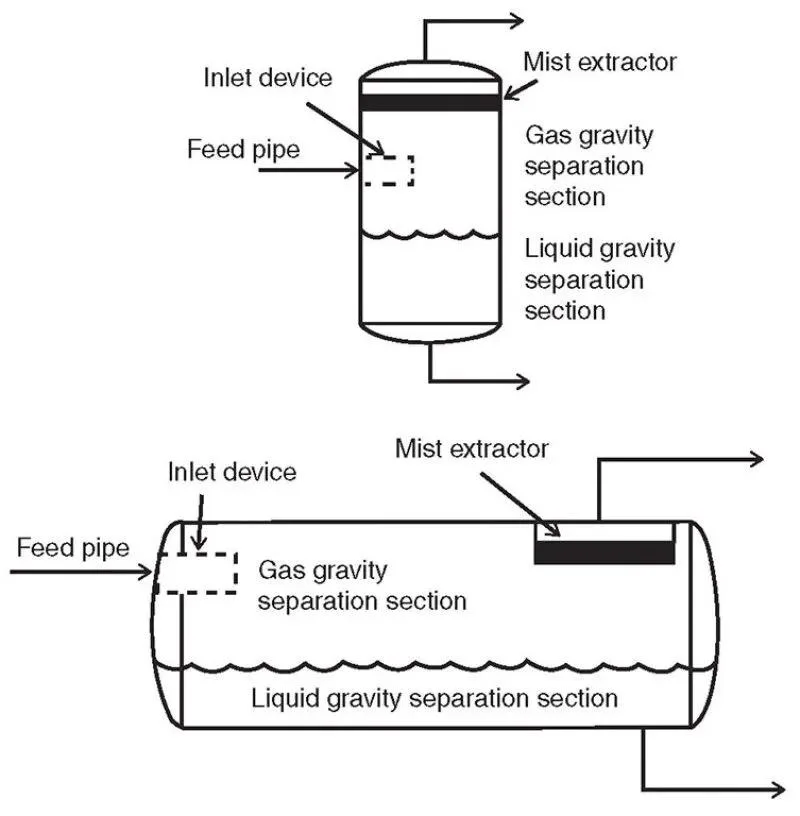

Steam water separator adopts the principle of centrifugal separation and screen filtration to realize a separation device of liquid removal. It is generally installed in front of the drying device to remove part of the moisture in the air by coarse filtration, so as to reduce the working load of the drying device. The main parts of a typical gas-liquid separator, vertical or horizontal, are shown in following picture, including the feed pipe, inlet device, gas gravity separation section, mist extractor, and the liquid gravity separation section.

The main parts of a typical gas-liquid separator, vertical or horizontal, are shown in following picture, including the feed pipe, inlet device, gas gravity separation section, mist extractor, and the liquid gravity separation section.

Main Technical Parameters and Indexes of Performance.

| Caliber | Design pressure (bar/g) | A | B | C | D | E | F | G | H | J | K | Weight | Volume |

| DN65 | 14 | 419 | 372 | 778 | 219 | 181 | DN25 | 3/4H | 100 | 263 | 30 | 60 | 19 |

| 22 | 419 | 372 | 778 | 219 | 181 | DN25 | 3/4H | 100 | 263 | 30 | 60 | 19 | |

| 31 | 419 | 372 | 778 | 219 | 181 | DN25 | 3/4H | 100 | 263 | 30 | 60 | 19 | |

| DN80 | 14 | 523 | 452 | 875 | 273 | 204 | DN25 | 3/4H | 125 | 368 | 30 | 95 | 34 |

| 22 | 523 | 452 | 875 | 273 | 204 | DN25 | 3/4H | 125 | 368 | 30 | 95 | 34 | |

| 31 | 523 | 452 | 875 | 273 | 204 | DN25 | 3/4H | 125 | 368 | 30 | 95 | 34 | |

| DN100 | 14 | 574 | 487 | 965 | 324 | 180 | DN50 | 3/4H | 125 | 384 | 40 | 75 | 52 |

| 22 | 574 | 487 | 965 | 324 | 180 | DN50 | 3/4H | 125 | 384 | 40 | 75 | 52 | |

| 31 | 574 | 487 | 965 | 324 | 180 | DN50 | 3/4H | 125 | 384 | 40 | 75 | 52 | |

| DN125 | 14 | 656 | 460 | 1013 | 377 | 247 | DN50 | 3/4H | 150 | 416 | 44 | 120 | 66 |

| 22 | 656 | 460 | 1013 | 377 | 247 | DN50 | 3/4H | 150 | 416 | 44 | 120 | 66 | |

| 31 | 656 | 460 | 1013 | 377 | 247 | DN50 | 3/4H | 150 | 416 | 44 | 120 | 66 | |

| DN150 | 14 | 706 | 497 | 1105 | 426 | 273 | DN50 | 3/4H | 140 | 466 | 60 | 115 | 110 |

| 22 | 706 | 497 | 1105 | 426 | 273 | DN50 | 3/4H | 140 | 466 | 60 | 115 | 110 | |

| 31 | 706 | 497 | 1105 | 426 | 273 | DN50 | 3/4H | 140 | 466 | 60 | 115 | 110 | |

| DN200 | 14 | 858 | 610 | 1370 | 530 | 372 | DN50 | 2H | 164 | 560 | 60 | 235 | 221 |

| 22 | 858 | 610 | 1370 | 530 | 372 | DN50 | 2H | 164 | 560 | 60 | 235 | 221 | |

| 31 | 858 | 610 | 1370 | 530 | 372 | DN50 | 2H | 164 | 560 | 60 | 235 | 221 | |

| DN250 | 14 | 950 | 765 | 1750 | 600 | 530 | DN50 | 2H | 169 | 688 | 72 | 375 | 400 |

| 22 | 950 | 765 | 1750 | 600 | 530 | DN50 | 2H | 169 | 688 | 72 | 375 | 400 | |

| 31 | 950 | 765 | 1750 | 600 | 530 | DN50 | 2H | 169 | 688 | 72 | 375 | 400 | |

| DN300 | 14 | 1010 | 890 | 1900 | 600 | 540 | DN50 | 2H | 200 | 698 | 72 | 676 | 400 |

| 22 | 1010 | 890 | 1900 | 600 | 540 | DN50 | 2H | 200 | 698 | 72 | 676 | 400 | |

| 31 | 1010 | 890 | 1900 | 600 | 540 | DN50 | 2H | 200 | 698 | 72 | 676 | 400 | |

| DN350 | 14 | 1100 | 904 | 2000 | 700 | 525 | DN50 | 2H | 200 | 816 | 108 | 971 | 660 |

| 22 | 1100 | 904 | 2000 | 700 | 525 | DN50 | 2H | 200 | 816 | 108 | 971 | 660 | |

| 31 | 1100 | 904 | 2000 | 700 | 525 | DN50 | 2H | 200 | 816 | 108 | 971 | 660 |

- High separation speed, high separator precision and good effect

- Highly integrated product, automatic and manual dual control, compatible with multiple control modes (direct+PLC+computer+DCS)

- The product is skid mounted in container type, which is convenient for moving and transportation, and more in line with safety production requirements;

- Low energy consumption, output 4-20mA and HART signal connection

- Humanized design, accept customized design and manufacturing according to customer requirements

Application:

Vertical separators are generally used when the gas-liquid ratio is high or gas volumes are high.

Horizontal separators are used where large volumes of liquid are involved.

The steam separators are very widely used in a great many industries and applications, such as: petrochemical and chemical plants, refrigeration systems, compressor systems, gas pipelines, paper mills, liquid ring pumps, steam condensate flash drums, etc.

1.Pre-sales Service

- Offering comprehensive technical and business consultation services;

- Proposing the most suitable scheme and equipment for our clients;

- Designing and fabricating targeted products according to the special requirements of clients;

- Training periodically high qualified service technician.

2.After-sales Service

- Highly inspecting equipments in every working procedure, quality comes first;

- Fast & Safe Delivery;

- Assisting our clients for foundation construction of equipments;

- Dispatching engineers to install and debug equipments;

- Training the first-line operators on site;

- Regularly visit clients to solve production problems;

- Providing life-long maintenance service;

- Providing technical exchanging.

Storage Tank Vibrating Screen Double Disc Refiner

Our team has good knowledge and expertise in forming all type of materials into different shapes, our hard working and flexible craftsmanship is ready non-stop to execute the orders within the shortest possible lead time and to maintain our commitments with our clients. We always provide the most economical and efficient solutions for clients to maintain a sustainable business for the long-term.

With well-equipped professional engineers and strong technical ability, our company has been in machinery filed more than 20 years.

- We cooperate with superior material suppliers to ensure the quality.

- We do lots of tests on machine to ensure the high quality of the equipment before packing.

- Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support.

- " Keep Improving, Pursuing Excellence" is always kept forever.

Our products have good impression on all of customers, it helps client to save lots of manpower, improve efficiency. With good product quality and business reputation, we are deeply supported and loved by customers!

We cooperate with the professional forwarders, the forwarders are specialized in the transportation of machinery for many years.

The goods are usually packed with carton, pallet or wooden case well and transported to customers. We support the multiple modes of transportation for customer choose, including by sea, by truck, by air and others. Packing methods and transportation modes depend on customers' requirements.

FAQ

FAQ Q:What's kinds of information you need for quotation?

A: You can provide 2D/3D drawing or send your sample to our factory, then we can make according to your sample.

Q: What type of material surface finishes do you provide?

A: We offer a wide variety of material and finishing services to achieve almost any look and feel on your parts. We offer

treatments for metal, such as Polishing, Sandblasting, Zinc plating, Oxide black, Powder Coated,Sandblast Anodized, etc.

Q: How about your delivery time?

A: Generally, it will take 15 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q: How can you ensure the quality?

A: We have professional QC department to guarantee the quality from the beginning of production until goods finish.

Q: How about the transportation?

A: We support any mode of transportation you want, sea delivery, air delivery, door to door express, etc.

Q: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit ;We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.