Basic Info.

Model NO.

Dry Fermentation Unit

HS Code

84213990

Production Capacity

100 Sets/Year

Product Description

Dry Fermentation Unit

Product description:

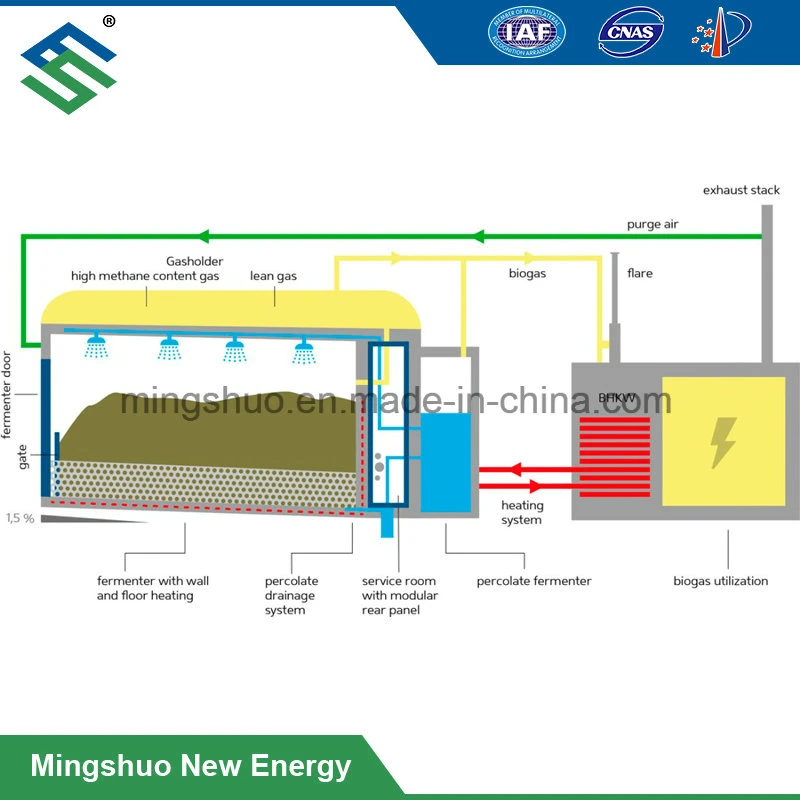

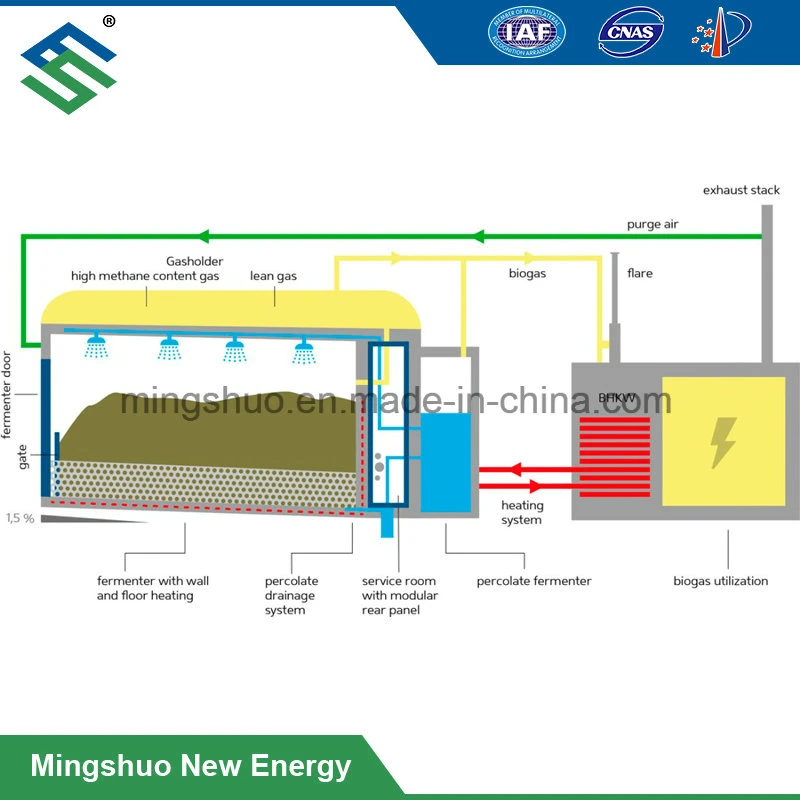

Dry Fermentation technology differs from traditional "wet digester" tank systems that utilize liquid feedstock and physically stir and agitate materials with moving parts. During the fermentation process, no further mixing, pumping or stirring is necessary inside the digester, nor is further material added.

The fermenters are characterized by having a generally common shape of the building. They are filled and unloaded using the front loader. Dry fermentation is a discontinuous process in which is the material in the fermentation boxes heated to operating temperature and spraying by the processing liquid. There is a depletion of oxygen in a short time and start on the process of anaerobic fermentation and biogas production in fermenters. The material remains approximately 4-5 weeks in the process. After this period biogas production is decreasing and the material is removed. Excessive percolation liquid is collected in a drainage system, temporarily stored in the percolation tank, and then re-sprayed over the biomass in the digester.

The residual material can be used as valuable organic fertilizer or can be further composted. Produced biogas is burned in a cogeneration unit which produces electricity and heat. Dry Fermentation is best suited for operations that process organic waste with a total solids content greater than 25%, including: Food waste, Yard clippings, Dry manure on bedding,Other high-solids waste.

Biogas dry fermentation technology is an effective way for energy disposal and utilization of organic solid wastes, biogas fermentation process reduces biogas slurry consumption, small reactor volume, high gas yield, in recent years has become a research hotspot in technology of solid organic wastes resources all over the world.

Dry biogas fermentation technology has the following advantages over the traditional wet process technology:

·feed TS% concentration is as high as 25%; heating energy consumption is less than 60%; installed capacity is small 50%, power consumption is saved; emission of biogas slurry is reduced by about 70%;

·the total volume of the fermentation tank is small, the system occupies an area of small;

·the fermentation materials without complex pretreatment, simplifies the process;

·the materials are allowed to contain more impurities, will not cause harm to the fermentation tank and equipment;

·less water consumption, low energy consumption, low heating demand, low consumption.

The significance of desulfurization:

Hydrogen sulfide is an inorganic compound. Under normal circumstances, it is a colorless, flammable acid gas. When the concentration is low, it has a foul smell and smells like rotten eggs. When the concentration is high, there is no smell, because high concentration of hydrogen sulfide can paralyze the olfactory nerve. It can be dissolved in water. At 0ºC, 1 mole of water can dissolve about 2.6 moles of hydrogen sulfide. The aqueous solution of hydrogen sulfide is called hydrogen sulfuric acid, which is a weak acid. When it is heated, hydrogen sulfide escapes from the water. Hydrogen sulfide is a kind of acute toxicity, which can be fatal in a short time by inhaling a small amount of high concentration hydrogen sulfide. Low concentration of hydrogen sulfide has effects on eyes, respiratory system and central nervous system.

Hydrogen sulfide is a strong neurotoxin, which has a strong stimulating effect on mucous membrane. Tears, eye pain, intraocular foreign body sensation, photophobia, blurred vision, runny nose, burning sensation in throat, cough, chest tightness, headache, dizziness, fatigue, confusion, etc. appear after short-term inhalation of high-intensity hydrogen sulfide. In severe cases, brain edema and pulmonary edema may occur. When the concentration is extremely high (more than 1000Mg/m3), the patient may suddenly fall into a coma within a few seconds, resulting in lightning death. High concentration contact with conjunctiva causes edema and corneal ulcer. Long-term low concentration exposure can cause neurasthenia syndrome and autonomic dysfunction.

Environmental protection and new energy is the theme of development in the 21st century. The treatment of air pollution is imminent, among which desulfurization is very important.Biogas, natural gas, coke oven gas, semi-water gas, oil associated gas, gas and wastewater contain toxic gas of hydrogen sulfide, which seriously corrodes equipment and pipelines. Inhalation of a small amount can cripple Days and Nights in Wuhan and seriously endanger life. Sulfur-containing gases must be removed from hydrogen sulfide before they can be used as clean energy.

With the rapid development of economy, desulfurization treatment is the key to solve the problem of environmental pollution. It is a responsibility of our environmental protection industry to improve the desulfurization efficiency in an all-round way. To promote the continuous improvement of environmental quality, create the greatest value for the society and build a beautiful world with sky blue, green space and clear water!

Company profile:

Mingshuo Environmental Technology Group Co., Ltd. was founded in 2004. The company is located at No.8 West Ring Road, Yeyuan Street, Linqu County, Weifang City, Shandong Province. The registered capital is 88 million yuan, covering an area of more than 100 mu. Mingshuo is positioned in the R&D, manufacturing and sales of high-end environmental protection complete sets of equipment, and is also a project system integration and operation service provider.

The company's products are generally divided into two series: desulfurizer, desulfurization equipment and biogas equipment. Desulfurizer and desulfurization equipment are mainly used for the treatment of sulfur-containing gas in users such as biogas, natural gas, oil associated gas, shale gas, chemical fertilizer, coking, steel mills, petroleum refining and pharmaceutical industry; The biogas equipment is mainly used for the treatment of livestock manure, kitchen waste, organic waste, straw, sewage and other organic wastes, so as to realize high-value utilization and turn waste into wealth. Organic wastes are treated by biogas equipment to become three biogas, namely biogas, biogas residue and biogas slurry. Biogas can not only be used for power generation, heating, supplying households, but also for purifying natural gas. The biogas slurry can be used as organic fertilizer.

Company qualification:

The company has passed the 'Trinity' management system certification of quality, environment, occupational health and safety, and has the professional construction qualification of environmental protection engineering, the construction safety production license, and the D1 and D2 pressure vessel qualification. Obtained 28 patents for inventions and utility models, and participated in the formulation of national standards for biogas desulfurization equipment. It is a high-tech enterprise in Shandong Province, Weifang Desulfurization and Denitrification Engineering Laboratory and Weifang Biogas Equipment Engineering Technology Research Center. It has the right to import independently, and has won the titles of "China Green Products", "Excellent Products of China Renewable Energy and Energy-saving Products Technology Expo" and "China Famous Brand".

Sales market:

With reliable quality and excellent service, "Mingshuo" brand equipment sells well all over the country, and is exported to Asia, Africa, America, Europe and Oceania, and exported to more than 20 countries and regions such as Malaysia, Japan, Uzbekistan, Indonesia, Iran, Thailand and Maldives.

Partners:

The Group has long-term cooperation with Sinopec, PetroChina, COFCO, CSIC, China Nengjian, Beijing Drainage Group, Yingfeng Environment, Huadian Group, Weichai Group, etc. It is a member unit of China Biogas Society, a member unit of china association of rural energy industry, China Biogas Research Institute, Process Research Institute of Chinese Academy of Sciences, Planning and Design Institute of Ministry of Agriculture, Tsinghua University, Shandong Chemical Planning and Design Institute, Agricultural University, Qingdao University of Science and Technology and other research institutes, and a cooperative unit with German national biogas expert Joe.

Company development philosophy:

Environmental protection is the theme of development in the 21st century, and the treatment of organic waste and air pollution is very important. It is our unremitting pursuit to optimize and upgrade the quality of environmental protection equipment, ensure the long-term safe operation of environmental protection projects, make Mingshuo products spread all over the world, make resources circulate infinitely, create a cleaner world and create the greatest value for the society. With the concept of "cherishing the limited, creating the unlimited", we will build an international leading system service provider for environmental protection and new energy industry.

Case presentation:

Product description:

Dry Fermentation technology differs from traditional "wet digester" tank systems that utilize liquid feedstock and physically stir and agitate materials with moving parts. During the fermentation process, no further mixing, pumping or stirring is necessary inside the digester, nor is further material added.

The fermenters are characterized by having a generally common shape of the building. They are filled and unloaded using the front loader. Dry fermentation is a discontinuous process in which is the material in the fermentation boxes heated to operating temperature and spraying by the processing liquid. There is a depletion of oxygen in a short time and start on the process of anaerobic fermentation and biogas production in fermenters. The material remains approximately 4-5 weeks in the process. After this period biogas production is decreasing and the material is removed. Excessive percolation liquid is collected in a drainage system, temporarily stored in the percolation tank, and then re-sprayed over the biomass in the digester.

The residual material can be used as valuable organic fertilizer or can be further composted. Produced biogas is burned in a cogeneration unit which produces electricity and heat. Dry Fermentation is best suited for operations that process organic waste with a total solids content greater than 25%, including: Food waste, Yard clippings, Dry manure on bedding,Other high-solids waste.

Biogas dry fermentation technology is an effective way for energy disposal and utilization of organic solid wastes, biogas fermentation process reduces biogas slurry consumption, small reactor volume, high gas yield, in recent years has become a research hotspot in technology of solid organic wastes resources all over the world.

Dry biogas fermentation technology has the following advantages over the traditional wet process technology:

·feed TS% concentration is as high as 25%; heating energy consumption is less than 60%; installed capacity is small 50%, power consumption is saved; emission of biogas slurry is reduced by about 70%;

·the total volume of the fermentation tank is small, the system occupies an area of small;

·the fermentation materials without complex pretreatment, simplifies the process;

·the materials are allowed to contain more impurities, will not cause harm to the fermentation tank and equipment;

·less water consumption, low energy consumption, low heating demand, low consumption.

The significance of desulfurization:

Hydrogen sulfide is an inorganic compound. Under normal circumstances, it is a colorless, flammable acid gas. When the concentration is low, it has a foul smell and smells like rotten eggs. When the concentration is high, there is no smell, because high concentration of hydrogen sulfide can paralyze the olfactory nerve. It can be dissolved in water. At 0ºC, 1 mole of water can dissolve about 2.6 moles of hydrogen sulfide. The aqueous solution of hydrogen sulfide is called hydrogen sulfuric acid, which is a weak acid. When it is heated, hydrogen sulfide escapes from the water. Hydrogen sulfide is a kind of acute toxicity, which can be fatal in a short time by inhaling a small amount of high concentration hydrogen sulfide. Low concentration of hydrogen sulfide has effects on eyes, respiratory system and central nervous system.

Hydrogen sulfide is a strong neurotoxin, which has a strong stimulating effect on mucous membrane. Tears, eye pain, intraocular foreign body sensation, photophobia, blurred vision, runny nose, burning sensation in throat, cough, chest tightness, headache, dizziness, fatigue, confusion, etc. appear after short-term inhalation of high-intensity hydrogen sulfide. In severe cases, brain edema and pulmonary edema may occur. When the concentration is extremely high (more than 1000Mg/m3), the patient may suddenly fall into a coma within a few seconds, resulting in lightning death. High concentration contact with conjunctiva causes edema and corneal ulcer. Long-term low concentration exposure can cause neurasthenia syndrome and autonomic dysfunction.

Environmental protection and new energy is the theme of development in the 21st century. The treatment of air pollution is imminent, among which desulfurization is very important.Biogas, natural gas, coke oven gas, semi-water gas, oil associated gas, gas and wastewater contain toxic gas of hydrogen sulfide, which seriously corrodes equipment and pipelines. Inhalation of a small amount can cripple Days and Nights in Wuhan and seriously endanger life. Sulfur-containing gases must be removed from hydrogen sulfide before they can be used as clean energy.

With the rapid development of economy, desulfurization treatment is the key to solve the problem of environmental pollution. It is a responsibility of our environmental protection industry to improve the desulfurization efficiency in an all-round way. To promote the continuous improvement of environmental quality, create the greatest value for the society and build a beautiful world with sky blue, green space and clear water!

Company profile:

Mingshuo Environmental Technology Group Co., Ltd. was founded in 2004. The company is located at No.8 West Ring Road, Yeyuan Street, Linqu County, Weifang City, Shandong Province. The registered capital is 88 million yuan, covering an area of more than 100 mu. Mingshuo is positioned in the R&D, manufacturing and sales of high-end environmental protection complete sets of equipment, and is also a project system integration and operation service provider.

The company's products are generally divided into two series: desulfurizer, desulfurization equipment and biogas equipment. Desulfurizer and desulfurization equipment are mainly used for the treatment of sulfur-containing gas in users such as biogas, natural gas, oil associated gas, shale gas, chemical fertilizer, coking, steel mills, petroleum refining and pharmaceutical industry; The biogas equipment is mainly used for the treatment of livestock manure, kitchen waste, organic waste, straw, sewage and other organic wastes, so as to realize high-value utilization and turn waste into wealth. Organic wastes are treated by biogas equipment to become three biogas, namely biogas, biogas residue and biogas slurry. Biogas can not only be used for power generation, heating, supplying households, but also for purifying natural gas. The biogas slurry can be used as organic fertilizer.

Company qualification:

The company has passed the 'Trinity' management system certification of quality, environment, occupational health and safety, and has the professional construction qualification of environmental protection engineering, the construction safety production license, and the D1 and D2 pressure vessel qualification. Obtained 28 patents for inventions and utility models, and participated in the formulation of national standards for biogas desulfurization equipment. It is a high-tech enterprise in Shandong Province, Weifang Desulfurization and Denitrification Engineering Laboratory and Weifang Biogas Equipment Engineering Technology Research Center. It has the right to import independently, and has won the titles of "China Green Products", "Excellent Products of China Renewable Energy and Energy-saving Products Technology Expo" and "China Famous Brand".

Sales market:

With reliable quality and excellent service, "Mingshuo" brand equipment sells well all over the country, and is exported to Asia, Africa, America, Europe and Oceania, and exported to more than 20 countries and regions such as Malaysia, Japan, Uzbekistan, Indonesia, Iran, Thailand and Maldives.

Partners:

The Group has long-term cooperation with Sinopec, PetroChina, COFCO, CSIC, China Nengjian, Beijing Drainage Group, Yingfeng Environment, Huadian Group, Weichai Group, etc. It is a member unit of China Biogas Society, a member unit of china association of rural energy industry, China Biogas Research Institute, Process Research Institute of Chinese Academy of Sciences, Planning and Design Institute of Ministry of Agriculture, Tsinghua University, Shandong Chemical Planning and Design Institute, Agricultural University, Qingdao University of Science and Technology and other research institutes, and a cooperative unit with German national biogas expert Joe.

Company development philosophy:

Environmental protection is the theme of development in the 21st century, and the treatment of organic waste and air pollution is very important. It is our unremitting pursuit to optimize and upgrade the quality of environmental protection equipment, ensure the long-term safe operation of environmental protection projects, make Mingshuo products spread all over the world, make resources circulate infinitely, create a cleaner world and create the greatest value for the society. With the concept of "cherishing the limited, creating the unlimited", we will build an international leading system service provider for environmental protection and new energy industry.

Case presentation: