- Overview

- Product Description

- Product Parameters

- Technical Advantage

- Detailed Photos

- Application

- FAQ

Basic Info.

Product Description

thermic Fluid Heater, thermal oil boiler, hot oil boiler

thermal capacity: 350kw-1400KW

Working pressure:0.8-1.0 MPA

Outlet temperature:320 C

Available fuel:natural gas, coke oven gas, bio-gas,liquefied petroleum gas, diesel, heavy oil, light oil, crude oil

Available industries:Petroleum, chemical, chemical fiber, pharmaceutical, textile printing and dyeing, building materials, wood processing, vegetable oil processing and other industries

YY(Q)W series thermal fluid boiler heater has skid-mounted design and full automatic control system. The heat carrier is thermal fluid oil, boiler's working pressure ≤1.0MPa, working temperature ≤310ºC. Adopting three-pass structure, 3 layer corrugated coil rings.

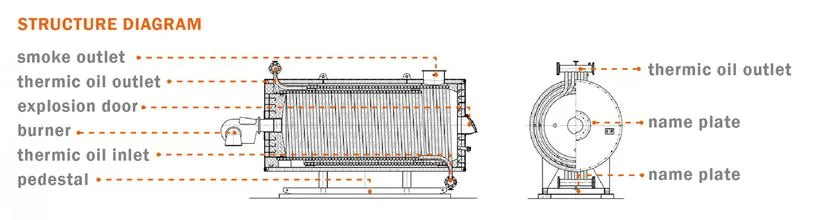

Working Principle Of Thermic Fluid Heater Oil-fired thermal oil boilers have a three-pass round coil structure. A conical coil is used for the effective protection of the furnace wall at the boiler end. This product is equipped with an advanced combustion device and is fully automated in operation. After the burner ignites the fuel, flame fills the round coil tubes and transfers heat by radiation through the tube wall (first pass). The high temperature flue gas gathers at the back door and then turns to the convection tubes section (second pass), where heat transfer takes place by convection. The flue gas gradually cools down here and flows to the front door, where it is reversed and goes into the third pass. After that, it enters into the chimney through the economizer and is released into the atmosphere.

Oil-fired thermal oil boilers have a three-pass round coil structure. A conical coil is used for the effective protection of the furnace wall at the boiler end. This product is equipped with an advanced combustion device and is fully automated in operation. After the burner ignites the fuel, flame fills the round coil tubes and transfers heat by radiation through the tube wall (first pass). The high temperature flue gas gathers at the back door and then turns to the convection tubes section (second pass), where heat transfer takes place by convection. The flue gas gradually cools down here and flows to the front door, where it is reversed and goes into the third pass. After that, it enters into the chimney through the economizer and is released into the atmosphere.

Thermal Oil Boiler (Heater) System This thermic fluid heater has advanced program control system, equipped with liquid level controller , pressure controller, temperature controller, and alarms to make sure the boiler work orderly and safe. So it is a kind of safe boiler with high efficiency and low power consumption.

This thermic fluid heater has advanced program control system, equipped with liquid level controller , pressure controller, temperature controller, and alarms to make sure the boiler work orderly and safe. So it is a kind of safe boiler with high efficiency and low power consumption.

Its advantage is Free-Installation

The complete boiler system is well skid-mounted on the basement, also we have done the pipe(valves) connection and wire connection. After receiving the boiler, user no need to do installation, just filling the thermal fluid oil, join the fuel and electricity. Entire boiler system is portable.

| Model No. | Thermal power(kcal/h) | Heating efficiency (%) | Max. working temp.(ºC) | Medium circulation(M3/H) | Transport size (mm) | Weight (Kg) |

| YY(Q)W-120Y(Q) | 10*104 | ≥92.26 | 340 | 12.5 | Φ1060*2045 | 1215 |

| YY(Q)W-240Y(Q) | 20*104 | ≥92.26 | 340 | 18 | Φ1020*1980 | 1355 |

| YY(Q)W-350Y(Q) | 30*104 | ≥92.26 | 340 | 30 | Φ1212*2310 | 1590 |

| YY(Q)W-500Y(Q) | 40*104 | ≥92.26 | 340 | 30 | Φ1212*2730 | 1680 |

| YY(Q)W-700Y(Q) | 60*104 | ≥92.26 | 340 | 60 | Φ1400*3410 | 2715 |

| YY(Q)W-900Y(Q) | 80*104 | ≥92.26 | 340 | 80 | Φ1616*3400 | 3142 |

| YY(Q)W-1200Y(Q) | 100*104 | ≥92.26 | 340 | 100 | Φ1616*4000 | 3660 |

| YY(Q)W-1400Y(Q) | 120*104 | ≥92.26 | 340 | 100 | Φ1820*4905 | 5420 |

| YY(Q)W-2000Y(Q) | 160*104 | ≥92.26 | 340 | 100 | Φ1840*4950 | 7850 |

| YY(Q)W-2400Y(Q) | 200*104 | ≥92.26 | 340 | 160 | Φ2060*4700 | 8850 |

| YY(Q)W-3000Y(Q) | 250*104 | ≥92.26 | 340 | 180 | Φ2060*5450 | 9210 |

| YY(Q)W-3500Y(Q) | 300*104 | ≥92.26 | 340 | 200 | Φ2430*5965 | 9960 |

| YY(Q)W-4100Y(Q) | 350*104 | ≥92.26 | 340 | 250 | Φ2630*6990 | 1120 |

| YY(Q)W-4700Y(Q) | 400*104 | ≥92.26 | 340 | 250 | Φ2830*7100 | 1230 |

Characteristics of heat-conducting oil boiler

1. The seal between the burner interface and the tube plate adopts a labyrinth type, which has good sealing performance and large expansion space, which prolongs the service life of the burner and improves the thermal efficiency.

2. The thermic fluid heater adopts two-coil structure, three-pass flue gas, compact design, saving space, adding air preheater, and thermal efficiency up to 92% or more.

3. Various operation safety protections make the boiler operation safer and simpler, with high temperature control accuracy (±1ºC) and good combustion effect.

4. The automatic control function is adopted to prolong the service life of the equipment while saving human resources.

5. Hot Oil Boiler can obtain a higher working temperature under a lower operating pressure, and has the technical characteristics of low pressure and high temperature.

6. It has complete operation control and safety monitoring devices, easy to operate, safe and reliable.

7. It can realize stable heating and precise temperature adjustment to meet different requirements

8. The thermal oil boiler has good thermal insulation, adopts high-efficiency thermal insulation materials and advanced construction technology, and has low heat dissipation loss on the furnace wall

The series of thermal oil heater is widely used in the following industries

l Petrochemical Industries:polymerization, melted, condensation, distillation, removal H2.

l Oil industry:fat and acid distillation, grease decomposition, concentrated, esterification, vacuum deodorizer, high-temperature cooking, advanced salad oil.

l Synthetic fiber industry: polymerization, melt spinning, extending; drying.

l Textile printing and dyeing industry: heat setting, hot melt dyeing, melt bake calendering drying, high temperature sterner, oar yarn.

l Plastics and rubber industry:hot pressing, hot cast, vulcanization molding, calendering injection machine, plastic mixer, conveyor dryer, screw ext-ruder.

l Paper Industry: dry, corrugated paper processing, egg tray, food cardboard drying, calendering machine, roller.

l Timber industry: multi layer plywood, fiberboard molding, plywood, wood drying, steaming equipment.

l Building materials industry: road bitumen heating, gypsum board drying, heating bitumen concrete, concrete elements curing, drying equipment.

l Air-conditioning industry:industrial plants, residential and hotel building heating.

l Detergent Industry: cooking boiler, autoclave, spray-washing tower, a conveyorized dryer, lipolysis device distillation column.

l The automotive industry:the tunnel-type drying room, degreasing baths, phosphate processing equipment.

l Electrical equipment industry: calendering machine, the platen machines, vacuum pan, dryer.

FAQ of thermal oil boiler

1.What is the highest temperature that thermal oil heater could achieve?

thermal oil heater can reach as high as 330ºC, and working under low pressure (<1.0MPa)

2.What are the heat-resistance temperature of grate and furnace?

The heat resistance temperature of grate is related to the grate material, the highest temperature could be as high as 1100ºC, and the lower temperature could be 700ºC.

The highest heat resistance temperature of furnace could be about 1700ºC~1800ºC.

3.What is conduction oil/ hot oil / heat transfer fluid?

Conduction oil has a high boiling point, it usually used for the industries that need the temperature of 150~350ºC, to instead of steam. The hot oil has the advantages of high transfer efficiency, fast heat transfer, and good thermal stability.