Basic Info.

Model NO.

TYR-10

Transport Package

Wooden Case

Specification

CE, SGS

Trademark

TOP

Origin

Chongqing, China

HS Code

84212990

Production Capacity

1000 Sets/Month

Product Description

Multi oil applications used hydraulic oil reclaiming equipment

(TYR Series)

Application

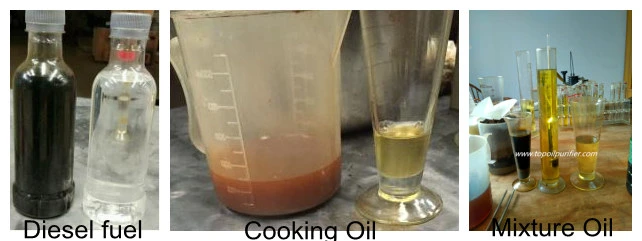

TYR series vacuum purifying and decoloring oil reclaiming equipment can apidly remove the color, moisture, impurities (particulate impurities and mechanical impurities) and gases(acetylene, hydrogen, methane etc) and other harmful ingredients etc. It can treat red diesel, hydraulic oil, machinery oil, coolant oil, cooking oil, coconut oil, sunflower oil, turmeric oil in oil field, mine, metallurgy, electricity, transportation, manufacturing, food industry. The treated oil is very clear and transparent.

TYR machine has mainly two systems: vacuum dewatering /degassing system & oil regeneration/decoloring system). It uses our special additive to discolor, which is pure natural and has high efficiency.

The machine can also be equipped with waste oil distillation plant to highly improve the dark oil color after distillation process.

Features: This machine adopts the the latest micro-filtration technology,which is a multi-functional purification system with vacuum oil filter, fine filter and decolorizing device.It uses purely physical treatment to remove water, gases, impurities and decolor,which will not affect the composition and performance of the oil. Equipped with chain protection device, the machine is easy to operate, safe and reliable.

II. Working Principle & Flow Chart c

When the equipment works, the oil is transported through the primary filter by the oil inlet pump to remove large particles and impurities and can protect the oil inlet pump, then the oil runs into the preheater for heating, so as to improve the liquidity of the oil, which is good for the next processing; after heating, the oil runs through the secondary filter by the effect of pressure to remove small particles in the oil, and then the oil enters the vacuum vessel where adopts the molecular separation technology and with certain vacuum and temperature condition, forming a large area of multi-level vacuum evaporation space. This space can provide the oil a a retention process with a large aeration area and aeration time, and ensure a effective separation of oil and gases or water vapors. The mixture of evaporated water vapor and gases is condensed into liquid through the cooler, and the gas is pumped out by the vacuum pump.In this way, it completes the dehydration and degassing treatment. The high temperature water vapor and other gases evaporated from the vacuum vessel are cooled for two times by the condensing cooler. Most of the gas is reduced to water and stored in the water receiver. After being repeatedly cooled and dehumidification, the uncondensed gas is discharged from the exhaust port of the vacuum pump. The dehydrated oil is exported out through the oil outlet pump, and runs through the fine fitler to remove the fine impurities and finish the fitleration process of dehydration and degassing. The pre-treated oil is returned to the oil storage tank, and then transported to the regeneration device to decolor by the oil pump. After a period of adsorption and neutralization treatment, it is sucked and stored in the tank by the vacuum vessel and transported to the fine filter through the oil pump and discharged from the oil outlet.Then we get the clean oil.

Technical Index

| Parameters | Unit | TYR-1 | TYR-2 | TYR-3 | TYR-5 | TYR-10 | TYR-15 | TYR-20 | TYR-30 | TYR-50 | |||

| Treatment Capacity | Ton/day (8 hr)) | 1 | 2 | 3 | 5 | 10 | 15 | 20 | 30 | 50 | |||

| Power Supply | 380V/50HZ/3Phase(Customizable) | ||||||||||||

| Working Noise | dB (A) | ≤65 | |||||||||||

| Trouble-free Working Time | H | ≥ 4000 | |||||||||||

| Continuous Working Time | H | ≥150 | |||||||||||

| Inlet (outlet) caliber | mm | Ф25 | Ф25 | Ф25 | Ф32 | Ф42 | Ф42 | Ф50 | Ф50 | Ф60 | |||

| Weight | kg | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | |||

| Size | Length | mm | 1800 | 1850 | 1900 | 1950 | 2000 | 2200 | 2300 | 2400 | 2500 | ||

| Width | mm | 1300 | 1350 | 1400 | 1450 | 1500 | 1600 | 1600 | 1700 | 1800 | |||

| Height | mm | 2300 | 2300 | 2300 | 2400 | 2500 | 2700 | 2700 | 2700 | 2700 | |||

| Guarantee value | Color | L | ≤ 1-3 | ||||||||||

| Impurity | μm | ≤1(Customizable) | |||||||||||

Flow chart of TYR series