Basic Info.

Model NO.

ZQ-8

Power

10-15kw

Total Weight

25-32tons

Oil Output(Tyre for Example)

90-95%

Type of Tire Machinery

Oil Extracting From Fuel Oil, Waste Oil, Crude Oil

Heating Way

Direct Heating /Indirect Heating

Installation

Assembled Boiler

Transport Package

Container

Specification

2600*6600*16mm

Trademark

ZQ

Origin

China

Production Capacity

1000

Product Description

Continuous Fuel oil/Waste oil/Crude oil Distillation Machine with CE & ISO &SGS

Certificate

Company Brief Introduction

Product Description

Advantages of Continuous Distillation Plant

1 Unique manufacturing and technology with our own formula of our equipment in China.

2 High oil output, about 80%-90%.

3 Good quality end product oil as the substitution of standard diesel oil in usage.

4 Security:

A. Adopting automatic submerged-arc welding technology

B. All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the welding shape.

C. Equipped with anti-explosive device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

5 Environmental-friendly:

A. Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke.

B. Smell during operation: Fully enclosed during the operation

C. Water pollution: No pollution at all.

6 Energy conservation and low cost on operation:

Special covers of the reactors and chambers can keep hot during the heating in good efficiency as well as the direct heating system to save energy and cost.

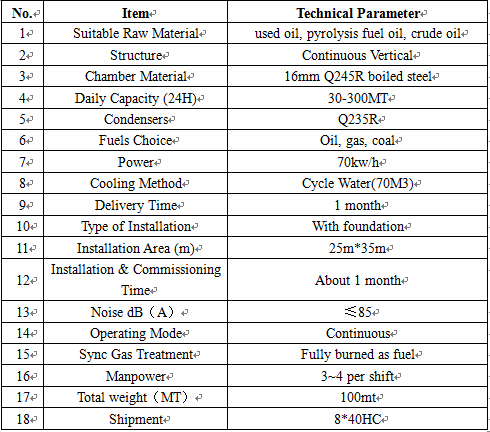

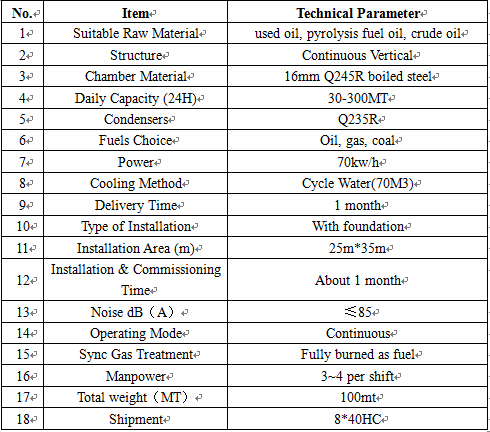

Technical Parameter of Continuous Distillation Plant

End Product and Percentage

The Oil distillation Plant with oil raw materials without water as example, the output is:

Oil Yield:80%-90% Sync Gas:≈3%

Residue:≈5% Inner Water:≈3%

Packaging & Shipping

1.Packaging Detail:

All the goods are packed according to export standard with no pollution:

2. Shipping Detail: 30 days after first deposit

Our Services

Pre-sales Service:

The wide product range enables us to provide our customers with machines or

Complete processing plants.Based on our customers' request and budget, our experts make efficient,

Reliable solutions.Following customers' order we produce strictly, what's more, before placing

The order every customer has the chance to visit working machines or complete plant in the site.

After-sales Service:

1.Quality warranty period: One year warranty for the reactor ,and lifetime maintenance for complete set of machines. pay the double air tickets, accommodation and food.

2.According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3.Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.

Certificate

Company Brief Introduction

Shangqiu Zhongqing Greentech Co,.Ltd is a professional institution engaged in the recycling and utilization of waste resources which includes scientific research, design, development, manufacturing, installation, commissioning, training and customer service. The headquarter of the company is located in Beijing. Our main equipment is waste tires equipment, waste oil sludge treatment equipment, living garbage equipment, electronic waste equipment, medical waste equipment, petrochemical waste equipment and related waste recycling equipment. We also undertake government environment project like engineering design, construction and testing date.

Product Description

Advantages of Continuous Distillation Plant

1 Unique manufacturing and technology with our own formula of our equipment in China.

2 High oil output, about 80%-90%.

3 Good quality end product oil as the substitution of standard diesel oil in usage.

4 Security:

A. Adopting automatic submerged-arc welding technology

B. All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the welding shape.

C. Equipped with anti-explosive device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

5 Environmental-friendly:

A. Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke.

B. Smell during operation: Fully enclosed during the operation

C. Water pollution: No pollution at all.

6 Energy conservation and low cost on operation:

Special covers of the reactors and chambers can keep hot during the heating in good efficiency as well as the direct heating system to save energy and cost.

Technical Parameter of Continuous Distillation Plant

End Product and Percentage

The Oil distillation Plant with oil raw materials without water as example, the output is:

Oil Yield:80%-90% Sync Gas:≈3%

Residue:≈5% Inner Water:≈3%

Packaging & Shipping

1.Packaging Detail:

All the goods are packed according to export standard with no pollution:

2. Shipping Detail: 30 days after first deposit

Our Services

Pre-sales Service:

The wide product range enables us to provide our customers with machines or

Complete processing plants.Based on our customers' request and budget, our experts make efficient,

Reliable solutions.Following customers' order we produce strictly, what's more, before placing

The order every customer has the chance to visit working machines or complete plant in the site.

After-sales Service:

1.Quality warranty period: One year warranty for the reactor ,and lifetime maintenance for complete set of machines. pay the double air tickets, accommodation and food.

2.According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3.Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.