Basic Info.

Product Description

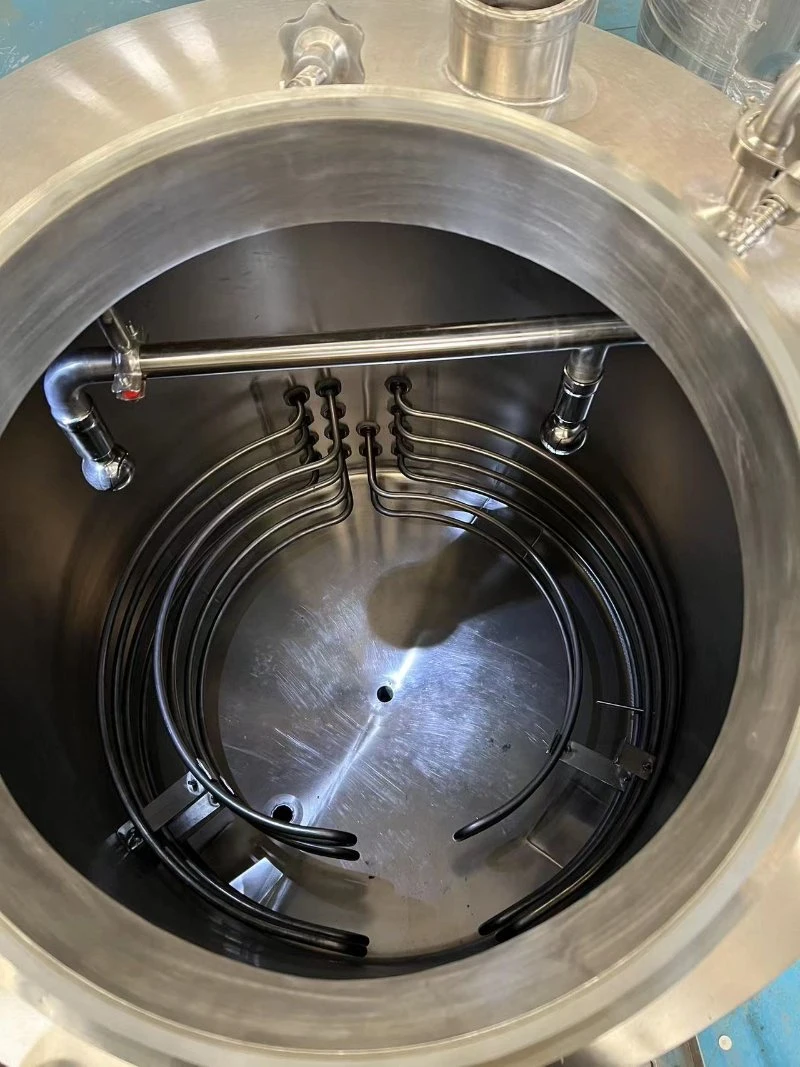

2000L Micro Brewery System Two vessels steam

| Model | CM-2000 |

| Capacity | 10000L/Batch |

| Pre-masher | 5000L/6000L |

| Mash Tun | 10000L/13000L |

| Lauter Tun | 10000L/14000L |

| Kettle | 12500L/16000L |

| Whirlpool | 10000L/14000L |

| Material | SUS 304/SUS316 |

| Combination method | Pre-masher/Rice cooker ,Mash tun,Lauter tun, Kettle,Whirlpool |

| Application | Brewery |

| Heating way | Steam heating |

| Voltage | According to the requirement |

| Automation | Fully automatic |

1000L BREWHOUSE Configurations

Malt Milling | · Double rollings crusher · Flexible or steel auger to directly lift the malt to mash tun |

Brewhouse | · Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination · Hot water tank and cold water tank for optional in special combinations · Stainless steel are popular because of easy maintenance and clean, copper cladding for optional · Two stages or single stage heat exchanger for wort cooling · Completely stainless steel integrated work platform · Sanitary and efficiency wort pump · All pipings and fittings |

Fermentation tanks | · Standard stainless steel conical cylindrical fermentation tanks · Single size or double size as brewhouse · Tanks quantity is exactly calculated by fermentation cycle for various beers · All manhole, valves, pressure gauges, fittings etc are included |

Beer Filters | · Plate-Frame or Candle type DE (diatomite earth) filter is used for clarify the beer |

Brite tanks | · Standard stainless steel bright tanks for beer maturation, conditioning, service, carbonation · Single size or double size as fermenter · All manhole, valves, stone, gauges, fittings etc are included |

Cooling System | · Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing · Efficiency chillers or refrigerators · Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger · All pipes, fitting, insulation materials are included |

Controlling Unit | · Electrical controlling cabinet with temperature, on-off controlling thermocouple, solenoid valves etc are included · PLC with touch screen panel for special request |

Beer Dispense | · Keg filling and rinsing machine · Semiauto bottling machine with rinsing, filling, capping, labeling etc · Flash pasteurizer or tunnel pasteurizer is available |

Other Facilities | · Portable or fixed CIP system for cleaning the tanks · Steam boiler for brewhouse heating · Water treatment for brew water · Oil free air compressor · Brewery lab instruments for beer quality test |

| Item | Production capacity | Volume in US Gallon | Heating area | Tank diameter | Height |

| CM-50 | 50L/day | 14US Gallon | 0.15m2 | 550mm | 1500mm |

| CM-100 | 100L/day | 26US Gallon | 0.25m2 | 650mm | 2000mm |

| CM-200 | 200L/day | 53US Gallon | 0.25m2 | 910mm | 2200mm |

| CM-300 | 300L/day | 79US Gallon | 0.3m2 | 910mm | 2300mm |

| CM-500 | 500L/day | 132US Gallon | 0.5m2 | 1160mm | 2400mm |

| CM-600 | 600L/day | 158US Gallon | 0.6m2 | 1160mm | 2500mm |

| CM-700 | 700L/day | 185US Gallon | 0.7m2 | 1260mm | 2500mm |

| CM-800 | 800L/day | 212 US Gallon | 0.8m2 | 1260mm | 2500mm |

| CM-1000 | 1000L/day | 264US Gallon | 1.0m2 | 1360mm | 2800mm |

| CM-1500 | 1500L/day | 396US Gallon | 1.5m2 | 1560mm | 2900mm |

| CM-2000 | 2000L/day | 528US Gallon | 2.0m2 | 1960mm | 3150mm |

| CM-2500 | 2500L/day | 660US Gallon | 2.5m2 | 1960mm | 3200mm |

| CM-3000 | 3000L/day | 792US Gallon | 3.0m2 | 2060mm | 3800mm |

| CM-5000 | 5000L/day | 1320US Gallon | 5.0m2 | 2260mm | 4400mm |