- Overview

- About Us

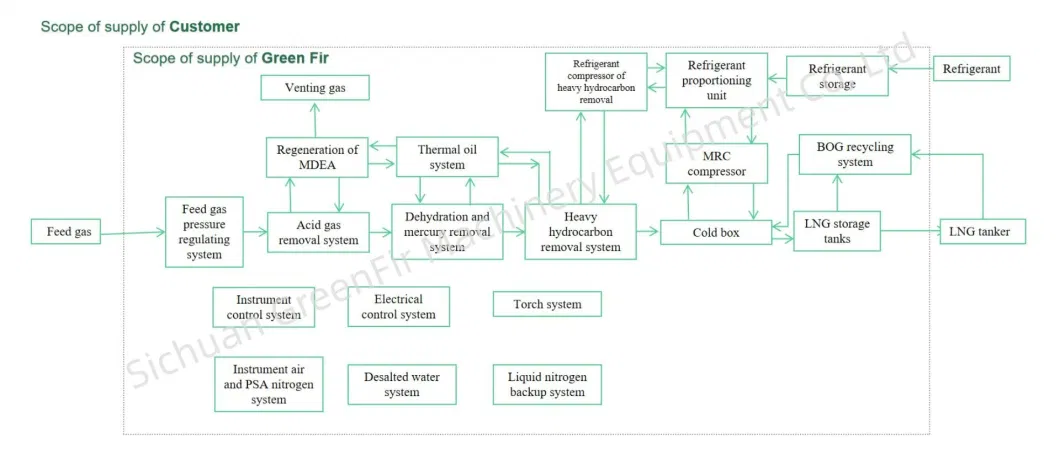

- Product Description

- Product Parameters

- Detailed Photos

Basic Info.

Product Description

Greenfir is a professional natural gas processing, liquefaction plant, air separation unit, heat exchanger, reciprocating piston compressor, cryogenic cold box, fractionating column manufacturer and solutions provider with ISO 9001: 2015, ISO 14001: 2015, ISO 45001: 2018 and ASME U certified.

Greenfir has successfully designed, manufactured and delivered more than 300 sets of natural gas purification, liquefication plants, air separation units, CNG filling stations, cryogenic cold box, etc. all-around China, Middle East, Central Asia and Southeast Asia, etc. We can deliver skid-mounted solutions customized to meet client's challenges and requirements (including adverse weather conditions, transportation and plot area limitations, etc.).

We treat all the cryogenic solutions with serious attitudes and professional experience. Combined with our knowledge and experience, Greenfir provides each client with a technology-leading solution you can count on and bring a wider range of options and more profits.

- technological block of gas treatment: a system for cleaning and drying high- pressure feed natural gas (complete with a regeneration gas heater, if a scheme with high-temperature regeneration of the adsorbent is implemented);

- natural gas liquefaction plant;

- cryogenic pumps;

- storage, distribution and gasification system;

- the product filling system and filling platform;

- gas treatment system;

- drainage and gas discharge system;

- pipelines for piping to the complex, including pipelines for supplying source gas to the complex from the GDS MG or CNG filling stations and returning the non- liquefied part of the gas;

- a compressor for compressing the vapors of evaporated liquefied natural gas in the case of LNG production at a pressure below the pressure in the line at the outlet of the GDS MG (CNG filling station);

- monitoring, control and emergency protection system;

- power supply system;

- regular and emergency lighting system;

- communication system (include telephone);

- gas analyzer.

1. Compact and modular design provides easy transportation and cheaper installation.

2. Ensuring the safety of equipment in accordance with the explosion-proof performance of class exdiibt4.

3. Easy start and stop of all systems.

4. Robust and reliable technology, easy to operate.

5. Quick deadlines for the completion of the project.

6. "Uninterrupted work of one team" together with clients to minimize the cost of the project and optimize the schedule.

| Operating Parameters of Skid-mounted LNG Plant | |||||

| Design Scale | 200,000Nm3/d | 300,000Nm3/d | 500,000Nm3/d | 1000,000Nm3/d | 2000,000Nm3/d |

| 7.6MMSCFD | 11.4MMSCFD | 19MMSCFD | 38MMSCFD | 76MMSCFD | |

| LNG Output | 148TPD | 222TPD | 370TPD | 740TPD | 1480TPD |

| Acid Removal Process | Activated MDEA | ||||

| Cool Method | Water cool | ||||

| Liquefaction Process | SMRC | ||||

| Design Life | 20 years | ||||

| Operating Flexibility | 85%~100% | ||||

| Continuous Operating Time | 8000h | ||||

1.Customized design and manufacture for all kinds of LNG plant are available.

2.LNG output is related to raw gas composition and pressure.

Please provide the following basic information when you inquiry. ^^

1) The LNG plant capacity?

2) Raw natural gas composition?

3) Raw natural gas inlet pressure and temperature?

4) Do you have cooling water system?

5) What the LNG outlet pressure do you need?

6) What's your Power condition? Voltage and frequency?