Basic Info.

Model NO.

889 Catalyst

Transport Package

Standard Export Packing

Specification

1kg/bag

Trademark

Mingshuo

Origin

China

HS Code

3824999990

Production Capacity

1, 000 Ton/ Year

Product Description

889 Catalyst for Wet Desulfurization in Biogas Plant

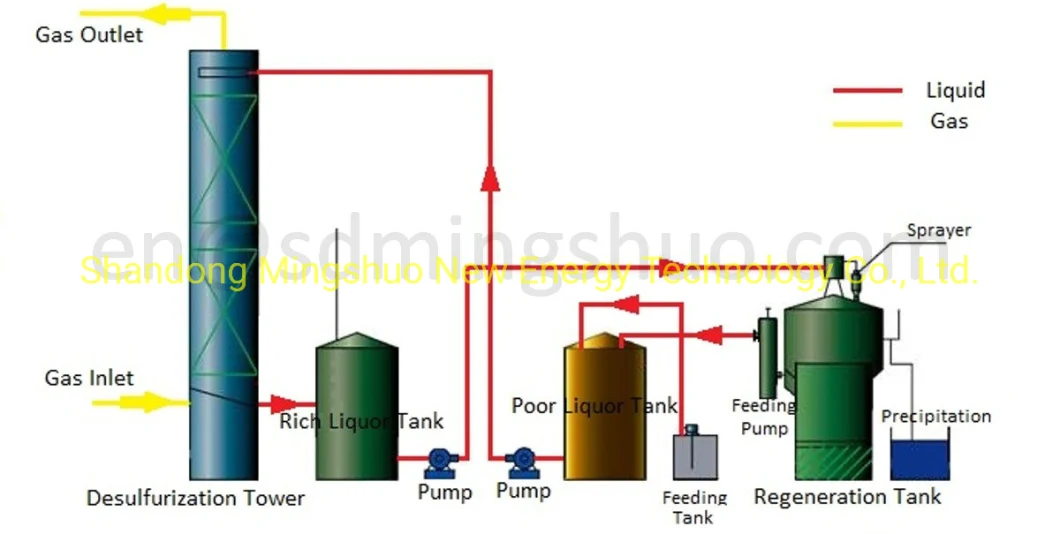

Wet Desulfurization Flow Chart:

889 desulfurization catalyst is the leading product of our company. On the basis of a series of other "cobalt phthalocyanine" desulphurization catalysts, the catalyst has been improved to enhance the performance of wet oxidation process. It has specific color, strong stability and high efficiency. It has high sulfur capacity and would not clog the equipment. Also, this catalyst has excellent sulfur cleaning ability, strong anti poisoning ability and good regeneration performance in the system. It produces large suspended sulfur particles, which is good for separation. It is suitable for desulfurization of gas containing hydrogen sulfide, mercaptan, carbon disulfide, carbonyl sulphur and so on. It is widely used in the desulphurization devices of half water gas, water gas, transform gas, coke oven gas, city gas, natural gas and biogas.

Adsorption: H2S + Na2CO3 == NaHS + NaHCO3/ H2S + NaOH == NaHS + H2O

Regeneration: 2NaHS + O2 =889= 2NaOH + 2S

Physical and Chemical Properties

1. Apperance: gray powder

2. Insoluble substance content: ≤3%

3. Density: 0.96 ± 0.05g/cm3

4. Catalytic activity: ≥0.2min-1

Characteristics and Performance

1. 889 desulfurization catalyst has advantages of strong catalytic activity, low dosage, economical and convenient operation and so on. When the old system changed to use "889", it does not need to stop and discharge desulphurizing solution.

2. The desulfurization efficiency is high, and the coarse desulfurization unit can reduce the H2S in the purified gas to below 50mg/Nm3.

3. It can be used for conventional desulfurization with H2S content less than 5.0g/Nm3, and also for desulfurization of high H2S concentration gas of more than 5~50g/Nm3.

4. The desulphurization process is comprehensive. It can remove both inorganic sulfur and organic sulfur. The desulfurization rate of organic sulfur is 50%~80%.

5. It would not plug the reaction tower. The sulfur particles selected are large during the regeneration process. Viscosity of the solution is low and seperation of sulphur is easy.

Project Display: 30,000m^3 Large-scale Wet Desulfurization System for Xiangchi Group

Management System Certification: ISO9001:2008, ISO14001:2004, OHSAS18001:2007

Company Introduction:

Shandong Mingshuo New Energy Technology Co., Ltd. Specializes in biogas project. The company is the production base of medium and large biogas equipments in China, the member of China Biogas Association, the member of China Association of Rural Energy Industry. The company is the recommended member of CCTV Website Enterprise Channel and China Import and Export Commodity Website, the most complete and excellent biogas equipments manufacturers in China. Mingshuo is a professional company integrating the scientific research, technological design, production and debugging service. The company specializes in the production of desulfurizer, desulfurization equipments and biogas equipments. Such as, Mingshuo MTZ biogas dedicated desulfurizer, MT ferric oxide desulfurizer, 889 wet desulfurization catalysts, water treatment agent, MS biogas dedicated desulfurization tanks, thioniers, biogas dedicated gas-water separators, assembled tanks, gas holders, positive-negative pressure protectors, biogas dedicated flame arresters, biogas boilers, deironing magnetic separation equipments, etc.

Contact: Emma Luan

Tel/Fax: +86 532 8576 2582

Phone: +86 176 6023 9752

Manufacturer & Supplier for Biogas Plant, Desulfurization System, Organic Waste Treatment Equipment etc.

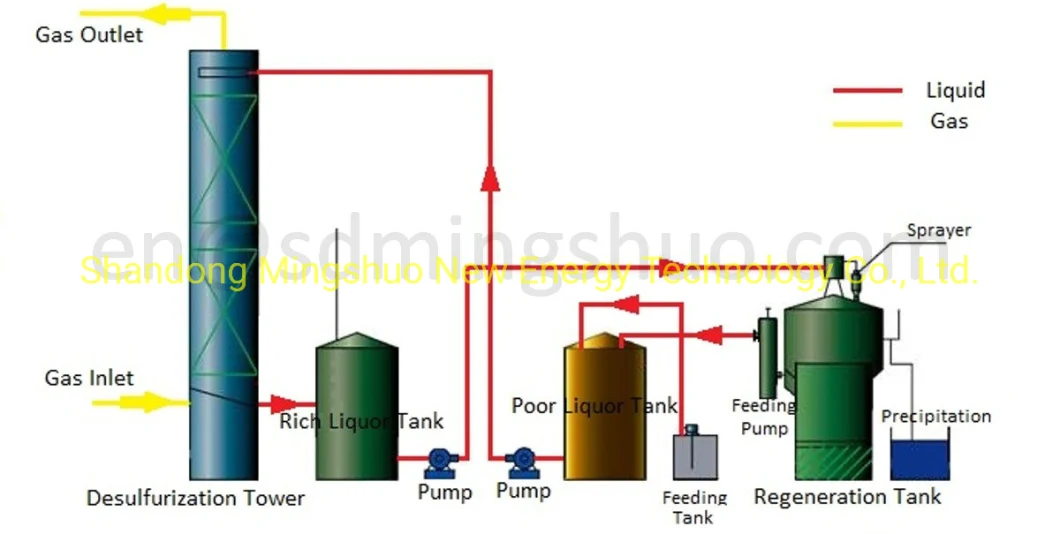

Wet Desulfurization Flow Chart:

889 desulfurization catalyst is the leading product of our company. On the basis of a series of other "cobalt phthalocyanine" desulphurization catalysts, the catalyst has been improved to enhance the performance of wet oxidation process. It has specific color, strong stability and high efficiency. It has high sulfur capacity and would not clog the equipment. Also, this catalyst has excellent sulfur cleaning ability, strong anti poisoning ability and good regeneration performance in the system. It produces large suspended sulfur particles, which is good for separation. It is suitable for desulfurization of gas containing hydrogen sulfide, mercaptan, carbon disulfide, carbonyl sulphur and so on. It is widely used in the desulphurization devices of half water gas, water gas, transform gas, coke oven gas, city gas, natural gas and biogas.

Adsorption: H2S + Na2CO3 == NaHS + NaHCO3/ H2S + NaOH == NaHS + H2O

Regeneration: 2NaHS + O2 =889= 2NaOH + 2S

Physical and Chemical Properties

1. Apperance: gray powder

2. Insoluble substance content: ≤3%

3. Density: 0.96 ± 0.05g/cm3

4. Catalytic activity: ≥0.2min-1

Characteristics and Performance

1. 889 desulfurization catalyst has advantages of strong catalytic activity, low dosage, economical and convenient operation and so on. When the old system changed to use "889", it does not need to stop and discharge desulphurizing solution.

2. The desulfurization efficiency is high, and the coarse desulfurization unit can reduce the H2S in the purified gas to below 50mg/Nm3.

3. It can be used for conventional desulfurization with H2S content less than 5.0g/Nm3, and also for desulfurization of high H2S concentration gas of more than 5~50g/Nm3.

4. The desulphurization process is comprehensive. It can remove both inorganic sulfur and organic sulfur. The desulfurization rate of organic sulfur is 50%~80%.

5. It would not plug the reaction tower. The sulfur particles selected are large during the regeneration process. Viscosity of the solution is low and seperation of sulphur is easy.

Project Display: 30,000m^3 Large-scale Wet Desulfurization System for Xiangchi Group

Management System Certification: ISO9001:2008, ISO14001:2004, OHSAS18001:2007

Company Introduction:

Shandong Mingshuo New Energy Technology Co., Ltd. Specializes in biogas project. The company is the production base of medium and large biogas equipments in China, the member of China Biogas Association, the member of China Association of Rural Energy Industry. The company is the recommended member of CCTV Website Enterprise Channel and China Import and Export Commodity Website, the most complete and excellent biogas equipments manufacturers in China. Mingshuo is a professional company integrating the scientific research, technological design, production and debugging service. The company specializes in the production of desulfurizer, desulfurization equipments and biogas equipments. Such as, Mingshuo MTZ biogas dedicated desulfurizer, MT ferric oxide desulfurizer, 889 wet desulfurization catalysts, water treatment agent, MS biogas dedicated desulfurization tanks, thioniers, biogas dedicated gas-water separators, assembled tanks, gas holders, positive-negative pressure protectors, biogas dedicated flame arresters, biogas boilers, deironing magnetic separation equipments, etc.

Contact: Emma Luan

Tel/Fax: +86 532 8576 2582

Phone: +86 176 6023 9752

Manufacturer & Supplier for Biogas Plant, Desulfurization System, Organic Waste Treatment Equipment etc.