Basic Info.

Model NO.

Hydrogen Sulfide Removal

Feedstock

Chelated Iron Catalyst

Equipment Material

Stainless Steel

Temperature

Normal

Gas Material

Gas Containing H2s

Appearance Color

Customized

Technical Support

Available

Service Time

30 Years

Function

Sulfur Removal

Transport Package

Standard Export Packing

Specification

Customized

Trademark

Mingshuo

Origin

China

HS Code

84213990

Production Capacity

100PCS/Year

Product Description

Chelate in regenerative h2s scrubber for pig farm biogas

Adopted international advanced technology, the new desulfurization device is uniquely designed and produced by our company in China. Iron-based wet desulfurization is a miniature high-efficiency desulfurization device independently developed by our company. It's designed with all-stainless steel structure, using an iron-based nutrient desulfurization liquid which is developed and produced by our company as catalyst, suitable for desulfurization of hydrogen sulfide containing gas. It has the characteristics of no pollution, low energy consumption, no need to consume alkali, high desulfurization precision, no need for secondary desulfurization, simple operation, long service life and by-product sulfur. The device can be mobile and skid-mounted, possible to be used or transported in container, widely used in the desulfurization of gases such as biogas, natural gas and oilfield associated gas.

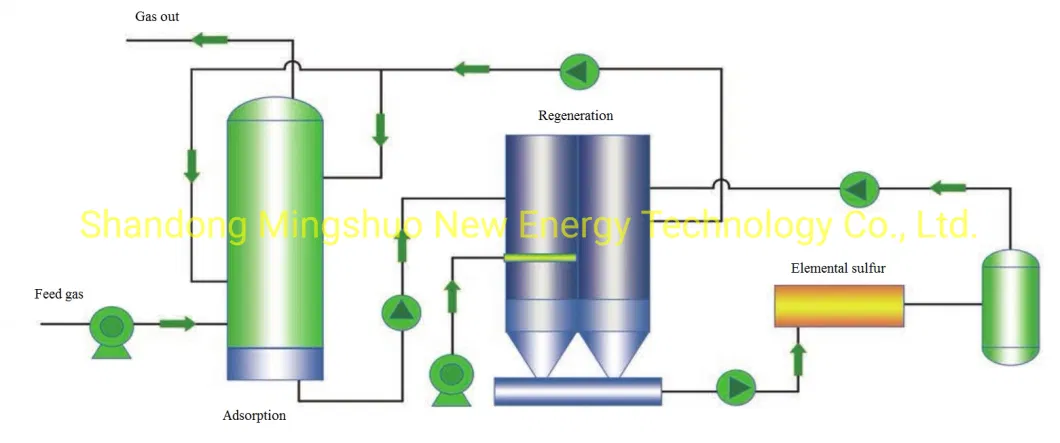

Process flow diagram:

Working principles:

H2S + 2Fe3+ → 2H+ +S↓ + 2Fe2+

1/2O2 + H2O + 2Fe2+ → 2OH- + 2Fe3+

Advantages:

1) No pollution, low energy consumption, no need of alkali,

2) High efficiency and precision, simple operation

3) Long service life (made of stainless steel) with by-product sulfur

| Comparison | Dry Desulfurization | Wet Desulfurization | Micro Chelated Iron Wet Desulfurization | Biological Desulphurization |

| Application | Small and medium projects with gas less than 5000m³/day; Second high precision desulfurization after other methods | Large Gas Plant up to 100,000 m^3/ day; High sulfur content around 5g/Nm³ | Large-scale | Large-scale, high sulfur-containing gas (100ppm~20000ppm) |

| Power Consumption | None | High | Moderate | Moderate |

| Operating Cost | Moderate, the desulfurizer need to be changed periodically | Moderate | Low | Low cost on electricity bill |

| Land Scale | Small | Full set of equipment for gas desulfurization, regeneration, filtration and melting sulfur, in result, large land is required. | Small | Moderate |

| Operation Management | Easy to manage, reliable operation, dispense with staff on duty | Need people on duty to control the operation | Need people on duty to control the operation | Automatic operation, simple maintenance |

| Remarks | Refueling at fixed period, one use one reserve, alternate operation | Many equipment | Less equipment than wet desulfurization | |

| Advantages | Simple structure, low investment, long lifetime, high precision of desulfurization (lower than 15ppm) | It can deal with large amount gas, and the system can run continuously by using PH value to keep the efficiency. | High efficiency by Iron Chelate, small in size, and high processing capacity | High desulfurization efficiency 99.5%, no second pollution, stable performance, suitable for large-scale, high sulfur-containing gas |

Management System Certification: ISO9001:2008, ISO14001:2004, OHSAS18001:2007

Company Introduction:

Shandong Mingshuo New Energy Technology Co., Ltd. Specializes in biogas project. The company is the production base of medium and large biogas equipments in China, the member of China Biogas Association, the member of China Association of Rural Energy Industry. The company is the recommended member of CCTV Website Enterprise Channel and China Import and Export Commodity Website, the most complete and excellent biogas equipments manufacturers in China. Mingshuo is a professional company integrating the scientific research, technological design, production and debugging service. The company specializes in the production of desulfurizer, desulfurization equipments and biogas equipments. Such as, Mingshuo MTZ biogas dedicated desulfurizer, MT ferric oxide desulfurizer, 889 wet desulfurization catalysts, water treatment agent, MS biogas dedicated desulfurization tanks, thioniers, biogas dedicated gas-water separators, assembled tanks, gas holders, positive-negative pressure protectors, biogas dedicated flame arresters, biogas boilers, etc.

Contact: Emma Luan

Phone: +86 176 6023 9752

Manufacturer & Supplier for Biogas Plant, Desulfurization System, Organic Waste Treatment Equipment etc.