Basic Info.

Model NO.

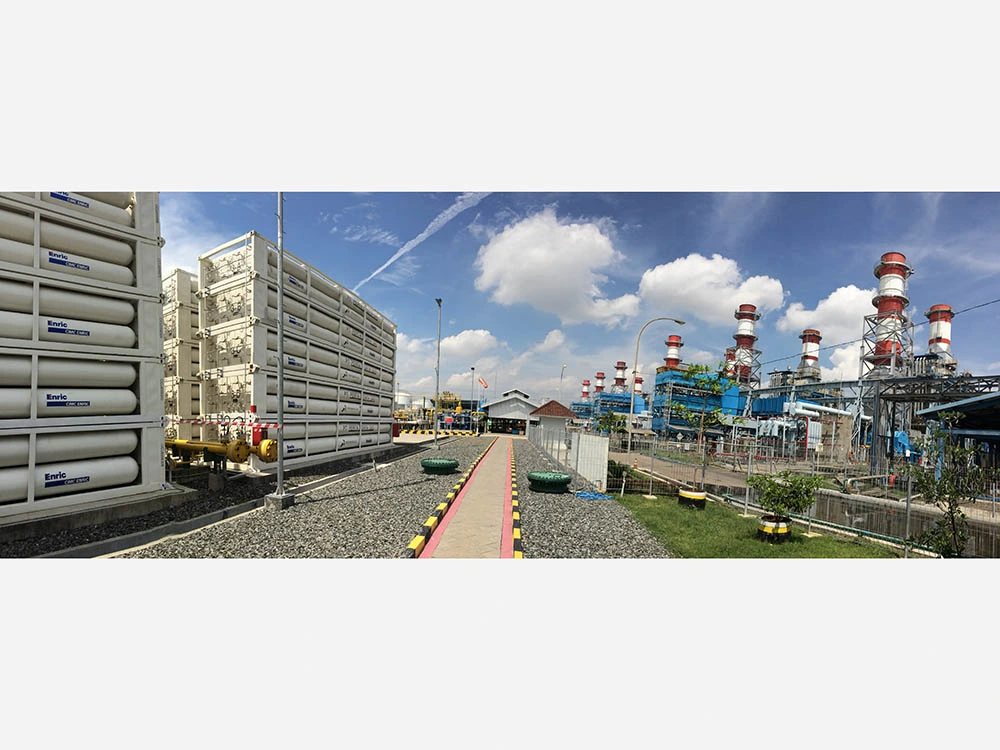

CNG SOLUTION FOR POWER PLANT

Condition

New

Certification

CE, CCC, Cu-Tr

Transport Package

40FT Container Vessel

Specification

12192*2438*2035

Trademark

SAINTWAH

Origin

Shandong

HS Code

7411290000

Production Capacity

10000

Product Description

CNG SOLUTION FOR POWER PLANT

The CNG solution for power plant project is to solve the peaker time operation cost for the power plant.

Compressed natural gas (CNG) can now be used as a fuel for gas-fuelled captive power plants. Natural gas as fuel source has a significant number of benefits versus diesel including reduced emissions and reduced fuel costs.

To use the natural gas to generate the electricity for the peaker time could make the operation cost decrease significantly and also environment friendly. The CNG tube skids could be arranged and installed according the site actually size and condition, the CNG solution for power plant project could be realize the remote control. The pressure sensor and temperature sensor could be installed with CNG tube skids, the instant signal could be transmit to the control room and the operators could monitor the status of the whole project. The whole system include CNG tube skids, compressors, PRU and flow meter could be designed and choose according to the gas engine parameter requirements. Enric has built several projects for the state own power plants in Indonesia, and these power plants now are in the smooth operation, and the cost is improved obviously.

he world needs an abundant supply of clean and affordable energy to support

economic and social progress and build a better quality of life, particularly in developing

countries. Until recently, this desire for energy has been met with fossil fuels, primarily

coal and oil.

Electricity is perhaps the most versatile form of energy and has a wide range of

applications . According to the law of conservation of energy, it is not possible to create

or destroy energy. Energy cannot be created from nothing, but fortunately it is possible

2

to convert energy from one form to another. Electrical energy can be obtained from

hydrocarbon fuels like coal, oil and gas, and primary energy flows like solar energy,

wind energy and geothermal energy. The use of natural gas in the power sector is

expected to increase over the next 20 years as it gains share from coal but falls back

by 2050 as the use of renewables accelerate. Electrical energy is easy to transport,

can be used to generate heat, power electrical motors to produce mechanical energy,

and power electronic devices.

In the seventh article in this series, Steyn (2021) discussed outlets and applications

for natural gas, including power generation. In this article, we describe the basics of

electric power generation in more detail and focus on the different options for

generating power from natural gas.

Basics of power generation

Opening remarks

Although sources such as electric batteries can supply electric power, it is mostly

produced by electric generators in power stations. The electric power system, often

referred to as the electric power grid, is made up of electricity generation, transmission,

and distribution. We briefly discuss power generators and primary drivers, and then

consider options for natural gas power generation.

Power generators

In 1831, the physicist Michael Faraday discovered that when a magnet is moved inside

a coil of wire, an electromotive force is induced which causes electrons to flow inside

the wire, generating an electric energy (Beck, 2018). A generator is any machine that

converts mechanical energy to electric current. For a generator to convert mechanical

energy into electrical energy, three conditions must exist for electromagnetic induction

to take place:

• There must be a magnetic field present.

• There must be an electric conductor adjacent to the magnetic field.

• There must be relative motion between the magnetic field and the conductor.

Most generators used in power stations are alternating current (AC) machines or more

specifically three phase rotating field synchronous AC generators, also known as

alternators. A synchronous generator delivers AC electrical power at a particular

voltage, frequency, and power factor . Each generator is coupled to a primary driver

(i.e., turbine or engine) and converts the mechanical energy of the driver into electrical

energy. In this case, in its simplest form, the magnetic field is provided by a permanent

magnet (or electromagnet) which is rotated within a fixed wire loop or coil in the stator.

The moving magnetic field due to the rotating magnet of the rotor will then cause a

sinusoidal current to flow in the fixed stator coil as the field moves past the stator

3

windings (conductors). If the rotor field is provided by an electromagnet, it will need

direct current excitation. If instead of a single coil in the stator, three independent stator

coils or windings, spaced 120˚ apart around the periphery of the machine, are used,

then the output of these windings can be interconnected and utilised in a three-phase

system, or utilised as three independent single-phase systems. The generated

electrical voltage is then stepped up with a transformer and then transmitted to where

it is requir ed.

Generator efficiency is the ratio of the electrical power output to the mechanical power

input. The efficiency of a very large generator can be as high as 98% or 99% but for a

1 000MW generator, an efficiency loss of just 1% means 10MW of losses must be

dissipated, mostly in the form of heat. To avoid overheating, special cooling

precautions must be taken and two forms of cooling are usually employed

simultaneously. Cooling water is circulated through copper bars in the stator windings

and hydrogen is passed through the generator casing. Hydrogen has a thermal

capacity 10 times that of air, giving it superior heat removal capability.

Electric grids in the world are either 60Hz (e.g., in the USA) or 50Hz (e.g., in Europe

and South Africa). When a two-pole generator is synchronized to the grid, it runs either

at 3 600 rpm (for a 60Hz grid) or at 3 000 rpm (for 50 Hz).

Primary drivers

Primary drivers provide mechanical energy to the generators which is the converted

into electrical energy. For power generation from natural gas, primary drivers comprise

turbines and gas-fired reciprocating engines. A cutaway of a Siemens industrial gas

turbine is shown in Figure 1.

Figure 1: Cutaway of a Siemens 593MW gas turbine (Siemens, 2021)

4

Turbines are used to convert the energy in a flowing fluid into mechanical energy using

rotor mechanisms. Gas turbines and steam turbines are thermal turbo machinery,

where the work is generated from the enthalpy change of the working fluid as it passes

through the turbine. Steam turbines are a mature technology and have been used since

the 1880s for power generation . Steam turbines use high pressure steam from a boiler

as the working fluid. Superheated steam entering the turbine loses its pressure

(enthalpy) moving through the blades of the rotors, and the rotors move the shaft to

which they are connected.

Gas turbines are internal combustion engines, using air as the working fluid. The

thermodynamic operation of the gas turbine is ideally modelled by the Brayton cycle.

Air from the inlet is first compressed using an axial compressor, which performs the

exact opposite of a simple turbine. The pressurised air is then directed through a

diffuser stage, in which the air loses its velocity, but increases the temperature and the

pressure further. In the next stage, air enters the combustion chamber, is mixed with

natural gas, and is ignited. As a result of the combustion, the temperature and pressure

of the resulting fluid rise to an incredibly high level. This fluid then passes through the

turbine section and produces rotational motion to the shaft.

Gas-fired engines a re simply reciprocating internal combustion engines designed to

run on natural gas and which produce rotational motion .

Options for natural gas

The different options for generating power from natural gas all deal with how the

chemical energy of the gas is converted to mechanical rotational energy to drive the

generator, as shown in Figure 2. Although there are many different types of generator s

for different applications, we will not elaborate on power generators, transformers,

transmission, and distribution.

Figure 2 : Options for power generation from natural gas

5

Each of the options for power generation from natural gas is discussed in more detail

in the sections that follow.

Steam turbine power plants

Opening remarks

Coal-fired steam turbine or thermal power plants make up most of the power generating

facilities in the world. thermal power plants. Electricity demand varies greatly by season

and time of day. Because thermal power plants can readily adapt to changes in

demand, it plays a central role in maintaining the baseload power supply.

Apart from coal, any other hydrocarbon fuels like oil or natural gas can be used to

generate steam for a thermal power plant. Alternatively, nuclear- and geothermal

energy can also be used for steam generation.

Technology

In steam turbine power plants, the thermal energy obtained from the fuel source is used

to convert water to superheated steam. The steam is used to drive a steam turbine

where the thermal energy is converted to mechanical rotational energy. The turbine is

connected to a generator where the mechanical energy is converted to electrical

energy. A simplified flow diagram of a steam turbine power plant is shown in Figure 3.

Figure 3 : Steam turbine power plant

The pressure and temperature of the steam falls to a lower value and it expands in

volume as it passes through the turbine. Depending on the design, the lower pressure

steam can be fed to further steam turbines on the same shaft to generate more power.

The example shown in Figure 3 has a high pressure (HP) and a medium pressure (MP)

turbine.

6

The expanded low-pressure steam from the final turbine stage is exhausted in the

condenser where cooling water is used to condense the steam into water for reuse in

the boiler. A boiler feedwater plant is required to supply make up water for steam and

condensate lost in the process.

Process efficiency

Considering that three conversion processes, thermal, mechanical, and electrical, are

used to extract the energy from fossil fuels, the overall efficiency of a modern

hydrocarbon fuelled electrical power generating plant will be about 40% (Lawson,

2020 a). This means that 60% of the energy input to the system is wasted. Efficiencies

may be <30% in some older plants. Actual efficiencies obtained depend on the fuels

used and the technical sophistication of the generating plant and processes.

Applications

Steam turbine power plants produce electrical power for the power grid. Apart from

hydrocarbon fuels, other heat sources can also be used to generate steam, i.e., nuclear

power, geothermal power, and waste heat from industrial processes.

No new facilities will be built using only natural gas as fuel solely for the purpose of

power generation. Better efficiencies can be had by opting for a natural gas-fuelled gas

turbine power plant. Natural gas can be used as a fuel in existing steam turbine power

plants as a replacement for coal.

Gas Turbine Simple Cycle power plants

Opening remarks

Gas turbine simple cycle power plants are significantly simpler than steam turbine

power plants. This is because it does not have the extra equipment (boiler, steam drum,

superheater, etc.) or complexity of a steam turbine.

A gas turbine simple cycle power plants comprises an integrated air compressor,

combustion chamber, and turbine (together called a gas turbine) and a generator.

Technology

Air is taken from the surroundings, compressed, and fed into the combustion chamber

where natural gas is introduced, and the mixture is ignited . The combustion process

instantly creates very high pressure and temperature gases. These gases then expand

through the turbine section and produce rotational motion (mechanical energy) to the

shaft.

With power generation, the gas turbine shaft is coupled to the generator shaft, either

directly, with a clutch mechanism, or via a gearbox. A flow diagram of a gas turbine

power plant is shown in Figure 4.

7

Figure 4: Gas turbine simple cycle power plant

Most of the energy of the natural gas is lost as waste heat in the exhaust gas in a

simple cycle power plant. This is not ideal for a baseload power plant.

Process efficiency

Simple cycle plants have great operational flexibility which means they can be started

up quickly. However, this comes at a lower efficiency compared to combined cycle

plants, as they make less use of the energy in the fuel they are using. The

thermodynamic efficiency of these plants is around 33%.

Applications

Gas turbine simple cycle plants are primarily used to provide peak power during

periods of very high demand because of their ability to quickly respond to demand

fluctuations.

Combined heat and power plants

Opening remarks

Combined heat and power (CHP) plants simultaneous generate usable heat and

electric power in a single process. Heat is captured to heat homes or for use in

industrial applications. CHP plants enable better overall utilisation of the heat energy

supplied to the system. CHP plants are also referred to as cogeneration plants.

Technology

CHP configurations use backpressure steam turbines to generate power and thermal

energy. Backpressure steam turbines produce low pressure steam. A typical CHP

installation is shown in Figure 5. After the thermal energy in the low pressure steam

8

has been consumed, the resulting condensate is returned to the steam boiler to

generate more steam. Heat from the exhaust gases from the combustion chamber can

also be used to heat the steam in the low pressure steam drum.

Figure 5: CHP power plants

The primary objective of most steam turbine CHP systems is to deliver relatively large

amounts of thermal energy, with electricity being generated as a by-product of heat

generation.

According to Lawson (2020b), small-scale or micro-CHP installations are now

becoming available for domestic use. The standard domestic heating boiler is replaced

by a heating unit which also provides the heat to power a Stirling engine, which in turn

drives an electrical generator. The Stirling engine is an external combustion engine

and works on the principle that gases expand when heated and contract when cooled.

Process efficiency

Efficiency figures for CHP installations are not comparable to that of other power

generation configurations because of the heat energy being used for other purposes

than power generation. Overall thermal efficiencies up to about 60% are possible.

Practical Stirling engines with efficiencies of 50% have been produced. This is double

the typical efficiency of an internal combustion engine which has greater pumping and

air flow losses in the engine and heat losses through the exhaust gases and cooling

system (Lawson, 2020b).

Applications

CHP installations are typically much smaller than what is found in power stations tied

to the grid and are owned and operated by individual commercial or industrial users.

The difficulty of finding a practical use for the surplus heat sets a limit to the size of

these systems.

9

Stirling engine generators with electrical power outputs between 1 kW and 10 kW are

available for domestic applications.

Gas turbine combined cycle power plants

Opening remarks

Exhaust gases are discharged to the atmosphere in the gas turbine simple cycle units.

In combined cycle power plants, the exhaust gases are used to generate steam in a

heat -recovery steam generator (HRSG) before being discharged.

The amount of generating capacity from natural gas-fired combined cycle plants has

grown steadily over time, and in 2018, surpassed coal-fired plants as the technology

with the most electricity generating capacity in the United States. As of January 2019,

U.S. generating capacity at gas-fired combined cycle power plants totalled 264GW,

compared with 243GW at coal-fired power plants (EIA, 2019a).

Technology

The first part of a gas-fired combined cycle power plant operates exactly like the gas

turbine simple cycle plant described above. However, instead of exhaust gases being

discharged to the atmosphere, the exhaust gases are used to generate steam in a

HRSG before being discharged. The steam so generated is used to power a steam

turbine and drive a second generator to generate more electric power. A simplified flow

scheme for a gas-fired combined cycle power plant is shown in Figure 6.

Figure 6: Gas turbine combined cycle power plants

Typically, the hot exhaust gases from several gas turbines will be used to generate

steam for a single steam turbine. An alternative arrangement also exists where the

10

steam turbine is mounted on the same shaft as the gas turbine to add additional

mechanical energy to drive a single generator.

Process efficiency

Siemens (2021) maintain that the efficiency of their SGT5-9000HL 593 MW gas turbine

based combined cycle plants can be as high as 64 % . General Electric (2021a) also

claim the same efficiency of their 9HA gas 571 MW turbine in combined cycle mode.

Applications

Gas turbine combined cycle plants are not as quick to start as simple cycle plants

because of the increased complexity. However, it can nevertheless be put on load in a

very short time . Gas turbine combined cycle plants are used as peak load, base lead

as well as standby plants.

Gas engine power plants

Opening remarks

Beside gas turbines, another way of utilising natural gas to generate electricity is by

using gas-fired internal combustion engines. When used to drive a generator, natural

gas engines are efficient and clean and have become popular for small-scale

distributed power generation applications. Internal combustion engines present an

efficient means of converting gaseous or liquid fuels into mechanical and electrical

energy.

Technology

Gas engine power plants are available in standardised designs comprising the gas-

fired internal combustion engine and the generator unit. Engines used are typically

spark-ignition engines. A flow scheme for a gas-fired internal combustion engine power

plant is shown in Figure 7.

Figure 7: Gas engine power plants

11

To reduce engine emissions during combustion of natural gas , the combustion

temperature is deliberately kept low by introducing more oxygen than is required for

complete combustion of the fuel, even though this reduces the efficiency that a

reciprocating engine can achieve significantly . Such engines are described as lean-

burn engines and can operate with an air to fuel ratio of between 20:1 and 50:1.

The greater proportion of air to fuel lowers the overall combustion temperature which

reduces the production of nitrogen oxides from nitrogen in air. More air also provides

the conditions for much more complete combustion of the fuel, resulting in reduced

carbon monoxide and unburnt hydrocarbons in the exhaust gases.

Process efficiency

Suppliers of gas engine power plants, or generating sets, claim electrical efficiencies

of between 48% and 51%, although with lean-burn engines will struggle to meet these

high efficiencies in normal operation . With heat recovery from the hot exhaust gases

when used in combined cycle mode, this can be pushed up further. High efficiency

translates into considerable savings in fuel costs compared to other technologies.

Gas engine power plants can achieve a plant availability of up to 95% and a warm start

up time of two minutes.

Applications

Wärtsilä, Jenbacher, Cummins, and Caterpillar, to name a few, provide natural gas-

based power generation solutions for baseload, peaking and standby operations.

Wärtsilä's gas and multi -fuel power plants are typically based on modular 4MW to

19MW internal combustion engine units. Jenbacher generating sets start at 250kW and

go up to 10MW electrical power output. Units from Cummins deliver between 13,5k W

and 3 400MW and Caterpillar has a range of 45kW to 10 900MW.

Reciprocating internal combustion engines are now becoming increasingly popular for

larger utility-scale power generation applications, especially in areas with high levels

of electricity generation from intermittent sources such as wind and solar (EIA, 2019b).

Environmental impacts

Great progress has been made in reducing the environmental impact of coal-fired

power stations, especially for pollutants like carbon monoxide, lead, sul phur dioxide

( SO 2 ), nitrogen oxides ( NOx ), ground-level ozone and particulate matter. A new

pulverized coal-fired power plant can reduce the emission of NO x by 83%, SO 2 by 98%

and particulate matter by 99,8%, as compared with a similar plant having no pollution

controls (Institute for Energy Research, 2017) . However, coal remains the dirtiest of

the fossil fuels and finance for future coal-fired power stations will be difficult to obtain.

12

Natural gas is composed almost entirely of methane and is considered the most

desirable of the fossil fuels for power generation. It is substantially free of particulate

matter, combustion is smokeless, and, because it is a gas, it mixes easily and intimately

with air to give complete combustion. The combustion of natural gas emits almost 30%

less carbon dioxide than oil, and about 45% less carbon dioxide than coal. Its

combustion produces negligible amounts of sul phur, mercury, and particulates. The

use of natural gas in place of coal or oil will thus contribute to reduced smog formation

acid rain, decarbonisation, and lower greenhouse gas emissions. Unfortunately,

methane itself is a greenhouse gas with the ability to trap heat almost 23 times more

effectively than carbon dioxide.

There are various opportunities to reduce greenhouse gas emissions associated

with electricity generation, transmission, and distribution. One way is to increase the

efficiency of fossil-fired power plants using advanced technologies and fuel

switching. For instance, convert coal-fired boilers to use natural gas and convert simple

cycle gas turbine installations to combined cycle facilities. Other options include greater

use of renewable energies and carbon capture and sequestration. General Electric

(2021b) believes that the world is best served by accelerating renewables deployment,

running existing gas plants more, and adding new gas capacity as the industry reduces

coal generation . The power sector's journey to lower carbon must be characterised by

rapid deployment of renewable energy resources and a rapid reduction in coal usage.

C oal-to -gas switching is a quick way to reduce emissions in many sensitive regions. In

addition, the possibility of switching turbines from natural gas to hydrogen , or natural

gas/hydrogen blends, when hydrogen becomes more freely available, makes the

prospect of a change to natural gas-powered power generation more tenable.

Closing remarks

When it comes to power generation , a switch from coal to gas represents a fast and

effective win for emissions reduction in many regions around the world. In future ,

switching turbines from natural gas to hydrogen fuel, and/or introducing carbon capture

and storage solutions, can lead to low or near zero carbon emissions . It is heartening

to see that the manufacturers of gas turbines and gas engines are working on

prototypes that will be able to switch over from natural gas to 100% hydrogen fuel with

minimal modifications.

The competitiveness of natural gas relative to coal in power production is highly

dependent on regional market conditions, particularly fuel prices. However, growth

prospects for gas are affected not only by the competitiveness of gas prices, but also

by recognition of the local air pollution and climate benefits of gas over coal. The

introduction of carbon taxes and regulation of plant emissions could encourage coal-

to -gas switching.