- Overview

- Product Description

- Detailed Photos

- Product Parameters

- Certifications

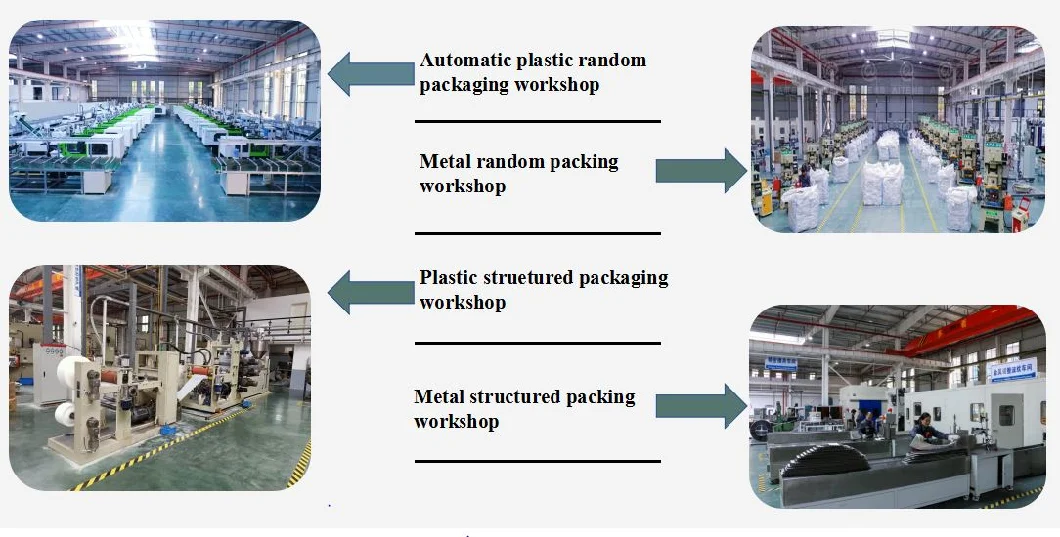

- Company Profile

- Application

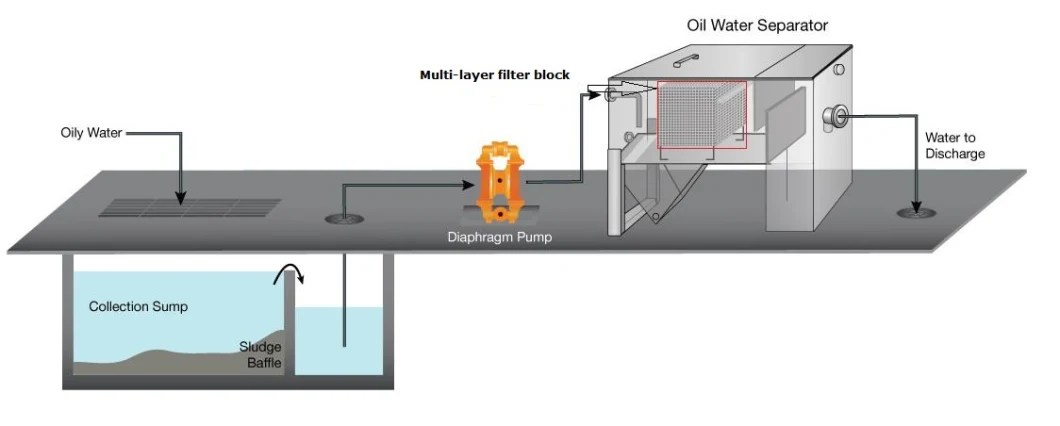

- Working principle

Basic Info.

Product Description

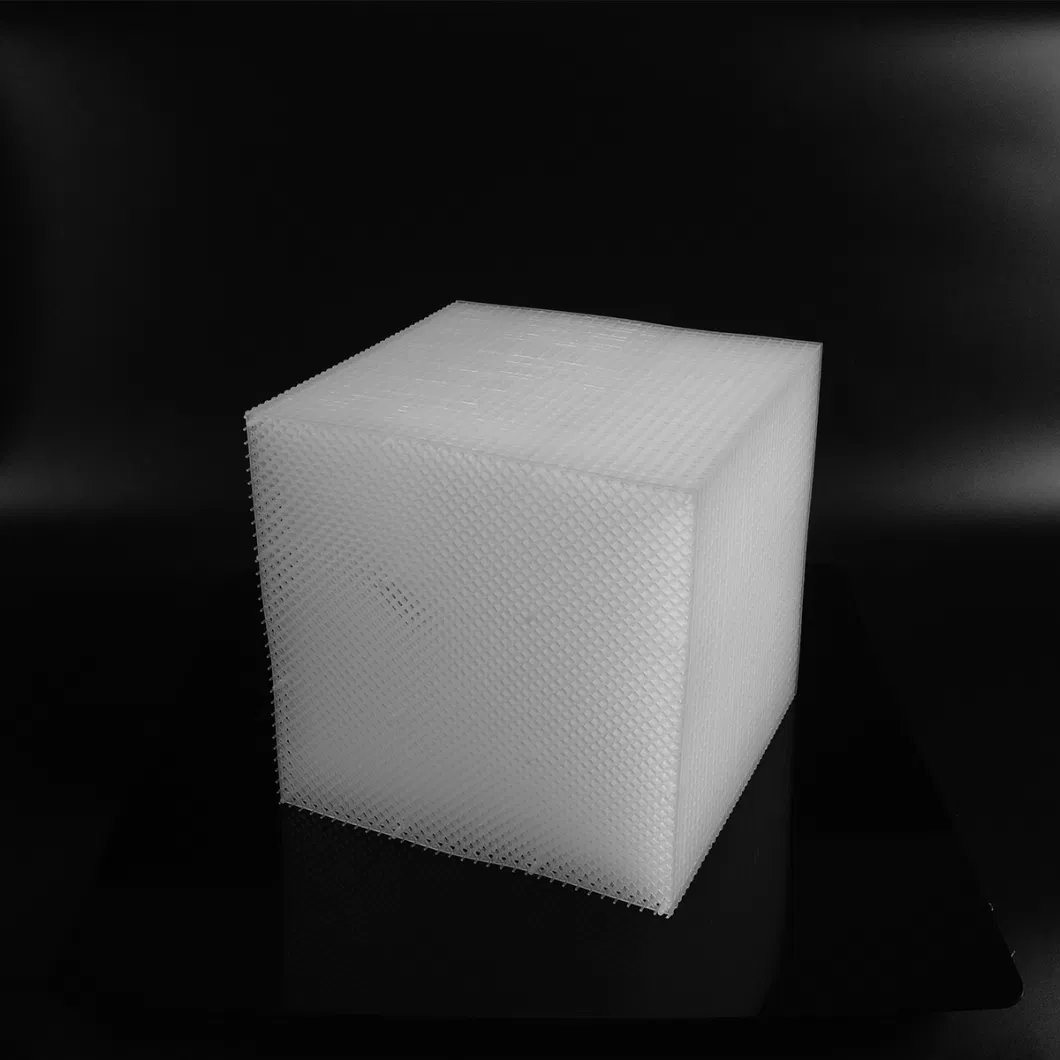

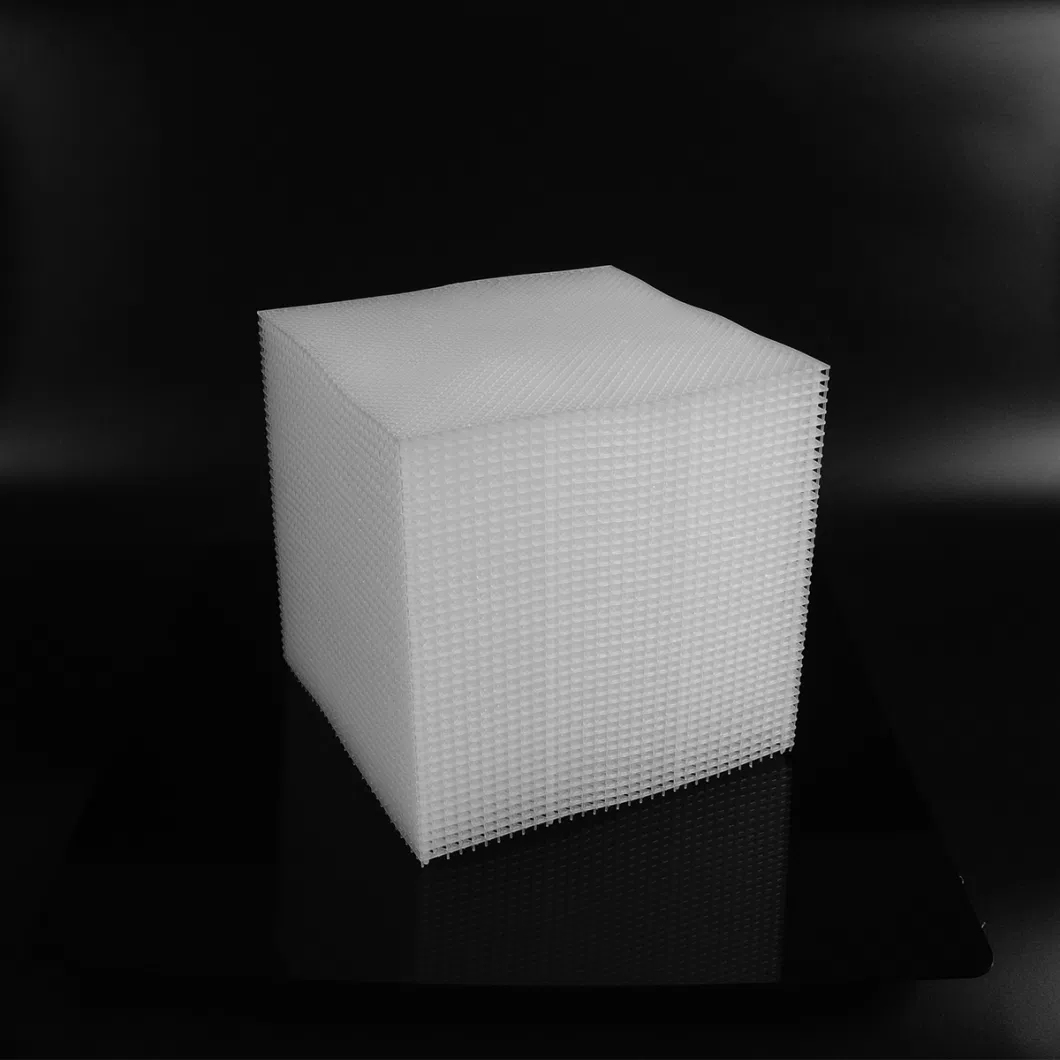

Coalescing separation media for oil water separator:

When certain materials are placed in the wastewater flow, removal efficiencies of oil increase due to impingement on their surface. Plastic media is particularly effective because of its oleophilic (oil attracting) characteristics. As fine oil droplets impinge upon or pass close to the plastic surface, they are attracted to it and adhere. Additional droplets continue to be attracted and coalesce or merge with previous droplets to produce much larger droplets. At a point, the droplets are large enough to break free and rise rapidly to the surface where they are skimmed or decanted. This coalescing action allows removal of smaller droplets than is possible with a straight gravity separator.

The effectiveness of any particular coalescing media is governed by several variables: density, available surface area, velocity, and direction of flow and shape of the media. All of these variables influence the potential contact area, so it becomes of particular importance to form the media properly to maximize contact while minimizing blinding. "The media pack was designed with consideration of all these factors. "The media pack provides greater coalescing and solids separation area than any other media currently available. "THE CUBE's®" patented shape and specific spacing of the plates provides maximum protection from blinding, while providing a tortuous path through which the water must pass. This continuous change of direction insures a high level of oil droplet contact on the cube surface with resultant coalescence and oil removal.

Feature:

1:Oil droplet removal efficiency can reach more than 99.98%

2:432 m²/m³ of effective coalescing surface. Removes over 99.9% of oil droplets 20 microns and larger.

3:Will not be degraded by microorganisms or sulfuric acid

4:The combination of a 90°angle of repose, with round smooth vertical surfaces and 87% void volume provide excellent self-cleaning and anti-plugging properties in oil water separators with heavy sludge, dirt and biological growth loadings.

5:Higher design flow rate of empty tower and smaller equipment size

6:Compared with Plastic structured packing, Avoid capillary action or short flow in porous media

7:Light weight, no equpped with support grid

8:100%'s bactiria attaching surface acrea, effectively sustain Flora active state

| Size mm | Surface area ft2/ft3 | Drip Points | Bulk Density Kg/m3 | Smallest Grid Opening mm | Void ratio % |

| 305*305*305 mm | 132 | 75000/ft3 | 7.5 lb/ft3 | 0.16"*0.16" | 87.8 % |

| 40*40*40 mm | 612 m2/m3 | No data | 170 Kg/m3 | 0.07"*0.07" | 93% |

Typical Application:

1:Eliminate the need for chemicals in odor-control scrubbers, or improve oil removal efficiency in compact oil-water separators.

2:Biological filming medium for Aquarium Life Support System in Aquarium

3:Wet scubber tower trickling biofilers

Use parallel corrugated plate technology that causes oil droplets to increase in size, and separate more quickly. We offer a unique inclined plate design, called HD Q-PAC. The Q-PAC is made of a structure of interconnecting plates with many crossing points. As the oil/water mixture flows through the separator, new droplets coalesce with retained droplets and form larger droplets. The enlarged droplets rise to the surface and decant from the separator.