- Overview

- Product Description

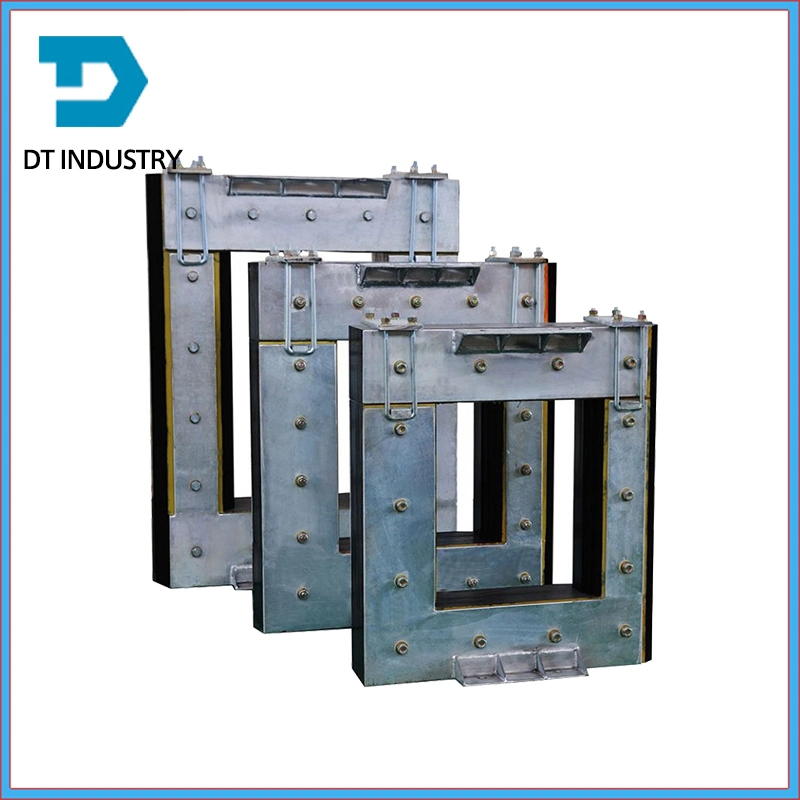

- Detailed Photos

- Product Parameters

- Our Advantages

- Company Profile

- You may like

Basic Info.

Product Name

Energy Efficient Coil

Name

Coil

Application

Copper and Brass Ontinuous Casting Industry

Raw Material

Ductile Iron

Usage

Foundry Pieces

Foundry Machine

Automatic Upward Casting Machine

Final Products

Oxygen Free Copper Rod

Technology

Copper Melting

Function

Inductor

Transport Package

Wooden Case / Cartons

Specification

Customization

Trademark

DT INDUSTRY

Origin

China

HS Code

8514909000

Production Capacity

1000000

Product Description

The characteristic of an induction furnace is that the electric heating power (current distribution) transformed in the heated material is very uneven, with the largest surface and the smallest center, known as the skin effect, in order to improve the electric heating efficiency of induction heating, the power supply frequency should be appropriate, Small melting furnaces or surface heating of materials should use high-frequency electricity, while large melting furnaces or deep penetration heating of materials should use medium frequency or power frequency electricity, induction coils are loads with a considerable amount of inductance, and their power factor is generally very low. In order to improve power factor, induction coils are generally connected in parallel with intermediate or high-frequency capacitors, known as resonant capacitors. The gap between the induction coil and the material should be small. The induction coil should be made of square copper tube, with water cooling inside the tube. The inter turn gap of the induction coil should be as small as possible, and the insulation should be good. induction heating device is mainly used for heating and casting steel, copper, aluminum, zinc, etc. it has fast heating, low burning loss, high mechanization and automation, and is suitable for configuration on automatic operation lines.

The characteristic of an induction furnace is that the electric heating power (current distribution) transformed in the heated material is very uneven, with the largest surface and the smallest center, known as the skin effect, in order to improve the electric heating efficiency of induction heating, the power supply frequency should be appropriate, Small melting furnaces or surface heating of materials should use high-frequency electricity, while large melting furnaces or deep penetration heating of materials should use medium frequency or power frequency electricity, induction coils are loads with a considerable amount of inductance, and their power factor is generally very low. In order to improve power factor, induction coils are generally connected in parallel with intermediate or high-frequency capacitors, known as resonant capacitors. The gap between the induction coil and the material should be small. The induction coil should be made of square copper tube, with water cooling inside the tube. The inter turn gap of the induction coil should be as small as possible, and the insulation should be good. induction heating device is mainly used for heating and casting steel, copper, aluminum, zinc, etc. it has fast heating, low burning loss, high mechanization and automation, and is suitable for configuration on automatic operation lines.

SPARE PARTS FOR FURNACE

Efficient copper coils

Cooling water Jacket

Copper molten ring

Transformer

Reactor

Iron core

voltage regulator

Refractory brick and material

Thermocouple thermometers

Graphite mold

--------Welcome to Customize--------

Efficient copper coils

Cooling water Jacket

Copper molten ring

Transformer

Reactor

Iron core

voltage regulator

Refractory brick and material

Thermocouple thermometers

Graphite mold

--------Welcome to Customize--------

| Product name | Water jacket/coil/iron core/regulator/reactor/molten ring | Technology | Brass Melting |

| Application | Casting Industries | Foundry Machine | Brass casting machine |

| Usage | Foundry Pieces | Material | Ductile Iron |

| Name | coil | Final products | Brass rod/ pipe |

| Type | Horizontal Continuous Casting Machine | Function | Inductor |

Making a perfect proposal for your production line;

Designing the suitable machines based on your requirements;

Manufacture machines you need;

Inspecting, packing, uploading and shipping service;

Offering all related auxiliary machines, spare parts and consumable tools;

Installing and adjusting machines on site and technology training your labors for operation;

Trial production on site till everything is going well;

On-site technology support if customer needs.

24 hours service online before sales and after sales.

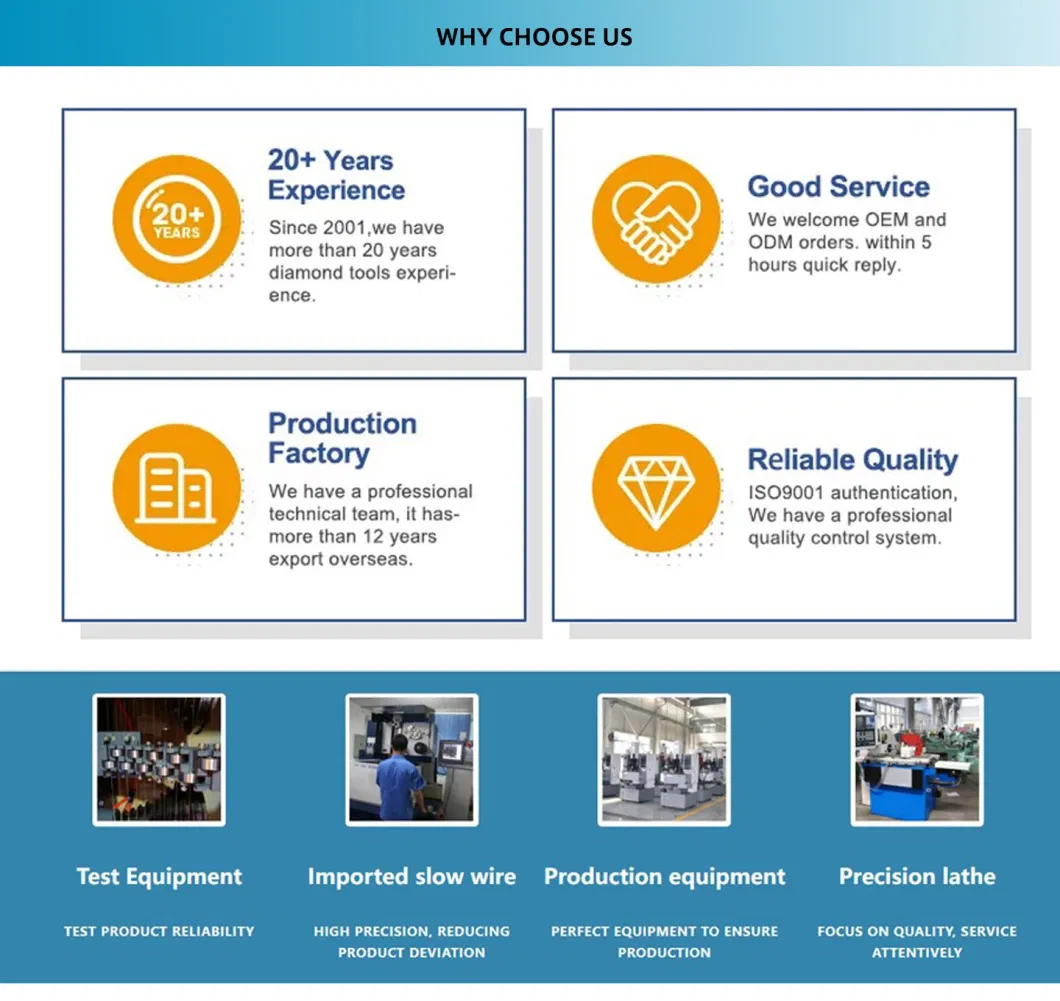

Guangzhou DT Exp. & Imp. Co. Ltd is established in 2012. We are mainly manufacturing machines for non-ferrous metal production.

The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.

Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.

We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.

Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.

Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.

The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.

Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.

We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.

Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.

Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.