- Overview

- Product Description

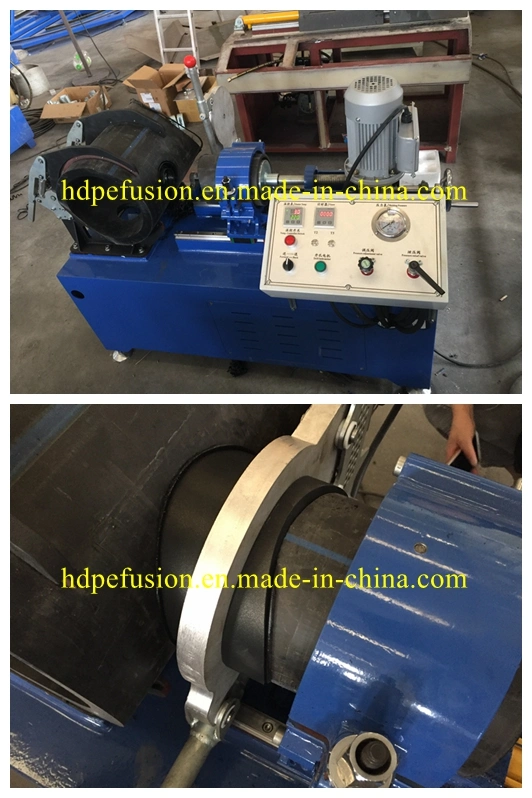

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Production Process

- Machine in Stock

- FAQ

- Contact Information

Basic Info.

Product Description

1.Suitable for fabricating PE reducing tee in a workshop. Integrated function of welding and taping enables it can complete the whole fabricating process

2.Removable PTFE coated heating mould

3.Control panel accompaines with CNC system to eliminate any risk of error due to the operator

4. Full-Automatic welding procedures with PLC and Touch screen

5. Welding statistics recording and printing function.

6. Linear guide ways are equipped with main pipe clamps, branch pipe clamps, knife tool and heat mould

Optional Parts:

* Heat Moulds

* Drilling Tool

| Model | MRH630 | MRH1200 | MRH1800 | MRH2000 | |

| Working range | Reducing tee | ||||

| Max. Temp heating plate | 270ºC | 270ºC | 270ºC | 270ºC | |

| System pressure ranges | 0~20MPa | 0~20MPa | 0~20MPa | 0~20MPa | |

| Working voltage | 380V,50Hz | 380V,50Hz | 380V,50Hz | 380V,50Hz | |

| Heating plate power | 6 KW | 16 KW | 25KW | 32 KW | |

| Hydraulic unit power | 2.2 KW | 2.2 KW | 3KW | 5.5KW | |

| Drill motor power | 2.2 KW | 3 KW | 4KW | 5.5KW | |

| Power | 10.4KW | 21.2KW | 32KW | 46KW | |

| Type | MRH630 | ||||||

| Main pipe Branch pipe | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| 110 | √ | √ | √ | √ | |||

| 160 | √ | √ | √ | √ | √ | √ | |

| 200 | √ | √ | √ | √ | √ | ||

| 225 | √ | √ | √ | √ | |||

| 250 | √ | √ | √ | ||||

| 315 | √ | ||||||

Q: Which parts of butt fusion machine are produced by your company?

Q: What's your delivery for standard machine?

Q: Can your company make non-standard machine?

Q: Does your company make custom-made machine?

Q: Does your company provide machine training?

A: It is available, you can choose to come to our factory to learn machine installation, operating, machine maintenance etc, also we can arrange our engineer to your factory for detailed training,even online training available too.