- Overview

- Product Description

- Company Profile

- Our Advantages

- Certification and Honor

- Partner & Cases

- After Sales Service

- FAQ

Basic Info.

Product Description

Functioin: This product is a skid-mounted gas-liquid mixed-transport booster, model YB1.4-110, which is specially designed for offshore oil Integrated skid mounted with gas-liquid mixed transport and pressurization function is specially designed and developed for natural gas production of gas treatment platform Let's put. The gas-liquid mixture produced from offshore oil and gas Wells is pressurized by this unit and directly enters the production flow. In this way, the operating back pressure of single well or multi-well area can be reduced to release production capacity and increase production.

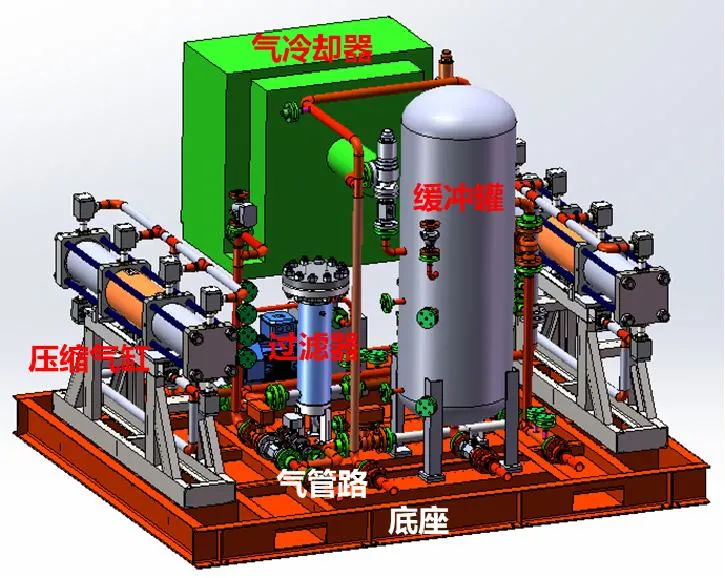

SystemThe mixed-transport supercharger is mainly composed of six parts:

Mixed-transport supercharging system

Hydraulic system

Process gas system

Cooling system

Control protection system

Base and equipment housing

Parameter:

| Medium | Gas oil liquid mixing |

| Inlet pressure | 2-7 Mpa |

| Intake temperature | 0-70ºC |

| Discharge pressure | 2-7Mpa |

| Discharge temp. | ≤55ºC |

| Ambient temperature | -19-45ºC |

| Ambient humidity | 30%~95% |

| CO2 RANGE | 2%~15% |

| Hydrogen sulfide content | No |

| Cool | Air cooler |

| Noise | ≤85Dba |

| Cylinder type | Horizontal type |

| Stage | 2 series/1 stage |

| Power | 110KW |

| Tank volume | 1200L |

| Size | 3.78m*2.95m*3m |

| Weight | 12t |

Compared with the advantages of traditional compressor product

YB type Drainage gas recovery compressor can reduce the flow pressure of gas well (gas well) by using compressor to increase the recovery rate of gas reservoir and achieve the purpose of tapping potential and increasing efficiency and protecting production and supply.

| Traditional Pressurization Process | Drainage gas recovery and supercharging device | |

| Component | Heating furnace, pressure reducer, separation tank, compressor, storage tank, trailer, etc | skid mounted mixed booster equipment |

| Investment costs | About 2 million | About 1 million |

| Construction cycle | One month | 2-3 days |

| Energy consumption | Heating furnace energy consumption Regulators waste energy Compressor needs to press high intake pressure distributor | Compressor with minimum inlet pressure distributor |

| Failure rate | High failure rate | Hydraulic system, low failure rate |

| Compressor leakage | Natural leakage of fillers Compressor shutdown | No leakage Compressor shutdown without emptying |

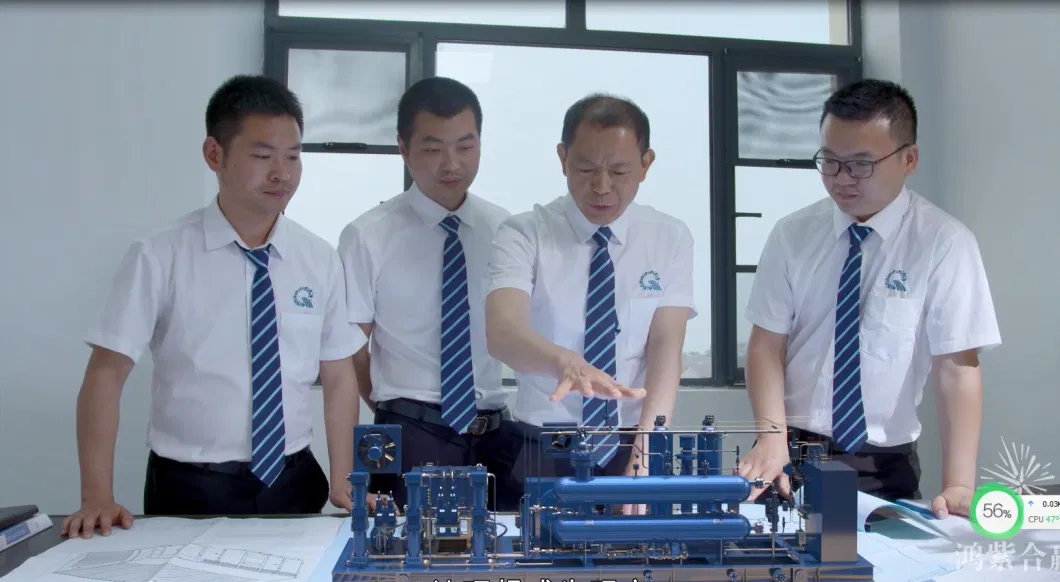

Wuhan Qidakon Energy Equipment Co., Ltd was established in 2007 in Wuhan, Hubei Province, with a plant covering an area of 18,000 square meters. We are specializing in the R&D, production and sales of natural gas compressor series products, we adhere to the professional, fine, specialty, brand development of the road, to provide customers with the best overall technical solutions of high-tech enterprises. Professional production and manufacturing of natural gas compressor for CNG filling station and its service, professional production and manufacturing of natural gas compressor for oil and gas field natural gas extraction, recovery, gathering and transportation, storage and transportation and after-sales service, products and services have covered the CNG market all over the country and major domestic oil and gas fields, and radiation to Russia, India and other Belt and Road foreign markets.

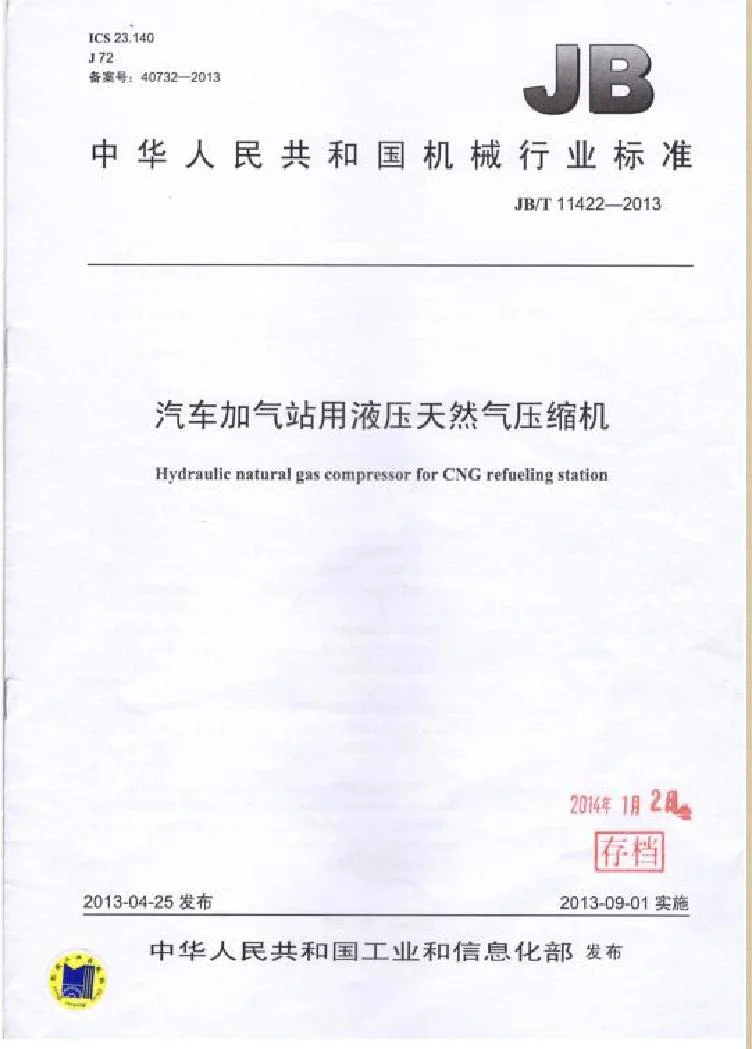

Qidakon company has always been committed to technological innovation. Its core business team has more than 30 years of working experience in compressor design and manufacturing, and led the drafting of the industry standard for hydraulic natural gas compressors for automobile filling stations (JB/T11422-2013). Obtained nearly 100 national patents, won the national technology innovation fund, and the first in the industry through the whole machine safety explosion-proof certification, by the Ministry of Science and Technology technology innovation fund committee identified as the national technology innovation products, with its "safety, energy saving, environmental protection, investment province, simple structure and many other advantages, in more than 20 provinces (autonomous regions) used, Market share is among the best, its technical advancement, reliability, economy and industry leading position by the national attention.

Qidakon adheres to the enterprise mission of "gas melts everything, the way to secure the world", adheres to the business philosophy of "customer first and sustainable development", forms the core values of "loyalty and dedication, innovation and transcendence, truth-seeking and honest, fair sharing" and the enterprise spirit of "persistence, cooperation, gratitude, tolerance, dedication", and is determined to become a global well-known brand of gas supercharging system.

Professional R&D Team

About 100 technical patents

Industry standard setter

The national industry standard JB/T 11422-2013 setter, Hydraulic Natural Gas Compressor for Automobile Filling Station, drives the technical progress of the industry and leads the development direction of the industry.

Advanced production workshop and strict production process

Sapare parts area Welding

Assemble skiding Pre-factory commissioning

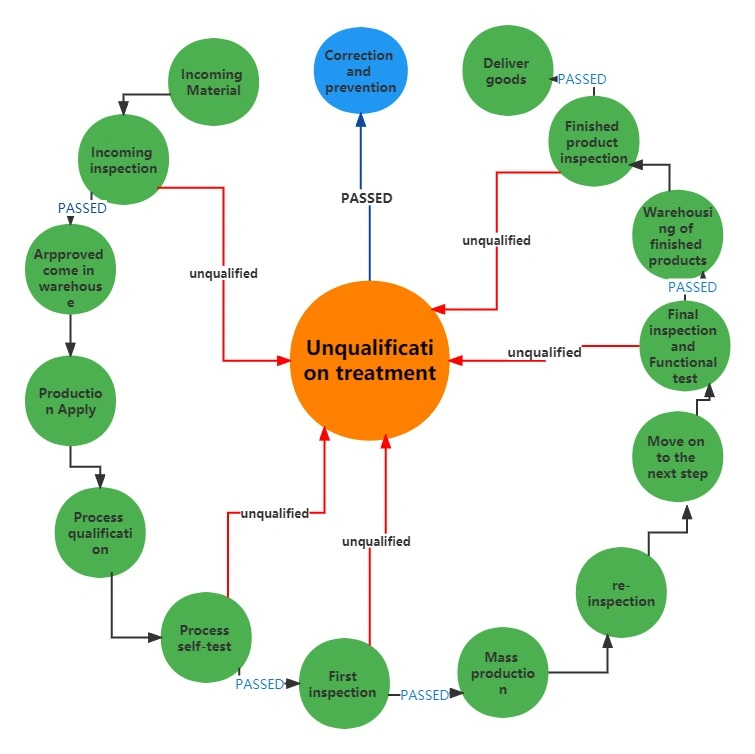

Strict quality control process and testing

CNG refueling station site

CNG refueling station site

Indian partner

Service Purpose: Cusomer's Satisfaction Our Pursuit

Pre- Sale Services

Provide installation and commissioning training for customer operators according to customer requirements. At the same time, organize and register product information and set up customer files.

Services on sale

The prodessional technical service engineer guides the installation and commissioning on the side or on the line. Andwarning of the possible failure of the equipment.

After-Sales Service

Timely and rapid response ,24-hour on-line service, provide lifelong maintenance.

1.How long is the lead-time of production?

2. What is the configuration of the whole skid equipment?

3.Which sea ports are supported for shipment?

4.What payment methods are supported?

5.What technical support is available?

6.How long is the warranty period?

For a period of 12 months from the date of commissioning at end customer site or 15 months from the date of receipt by purchaser , whichever is earlier.