Basic Info.

Product Description

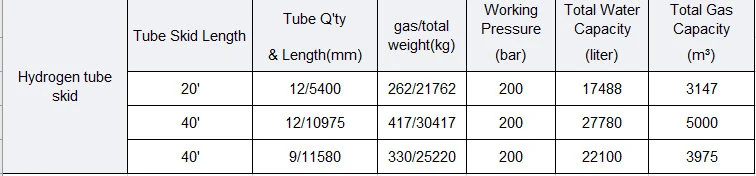

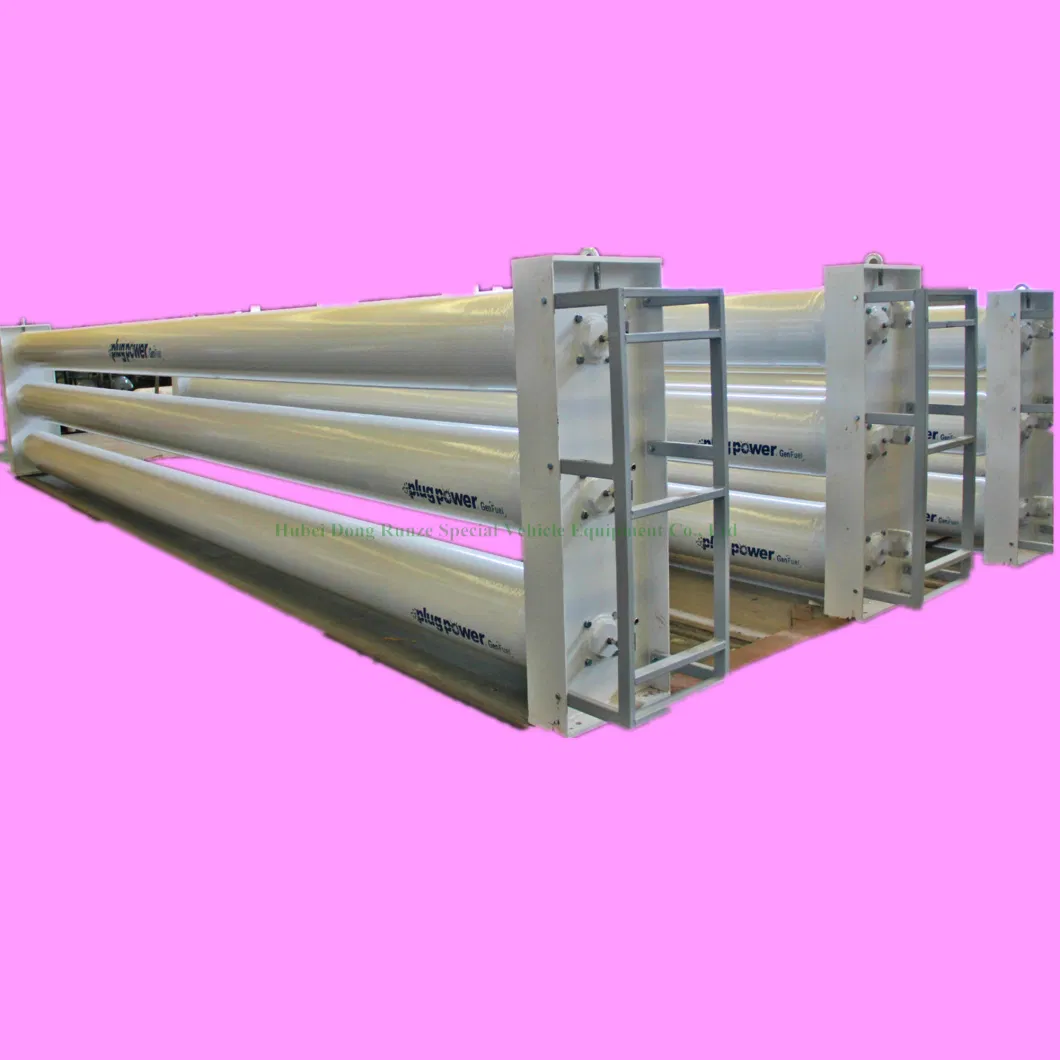

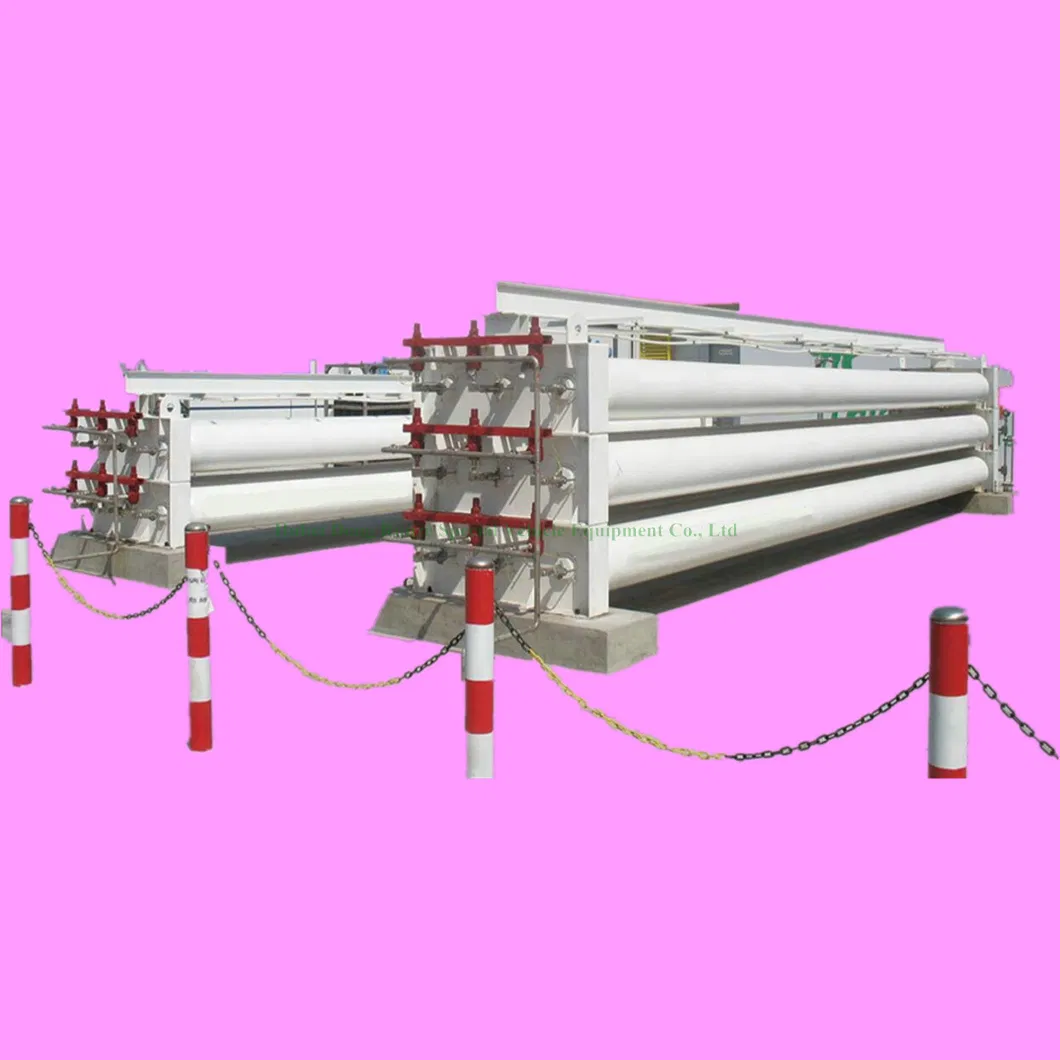

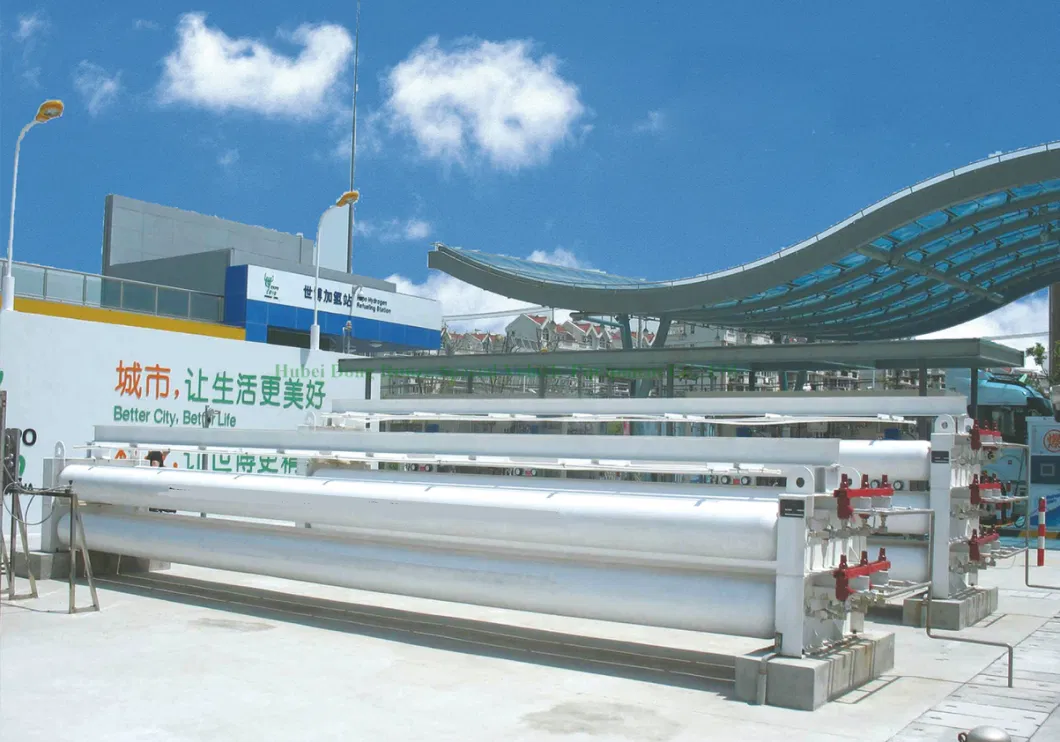

Hydrogen Transport Tank Mounted on Trailer(Cascade Gas Jumbo Tube Skid Delivery Gaseous Hydrogen /Helium Tube Trailer)

Compressed Natural Gas Cascade

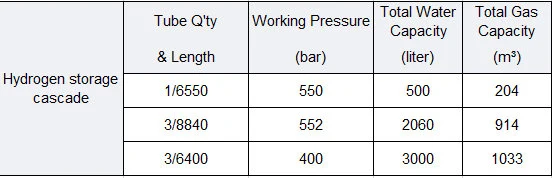

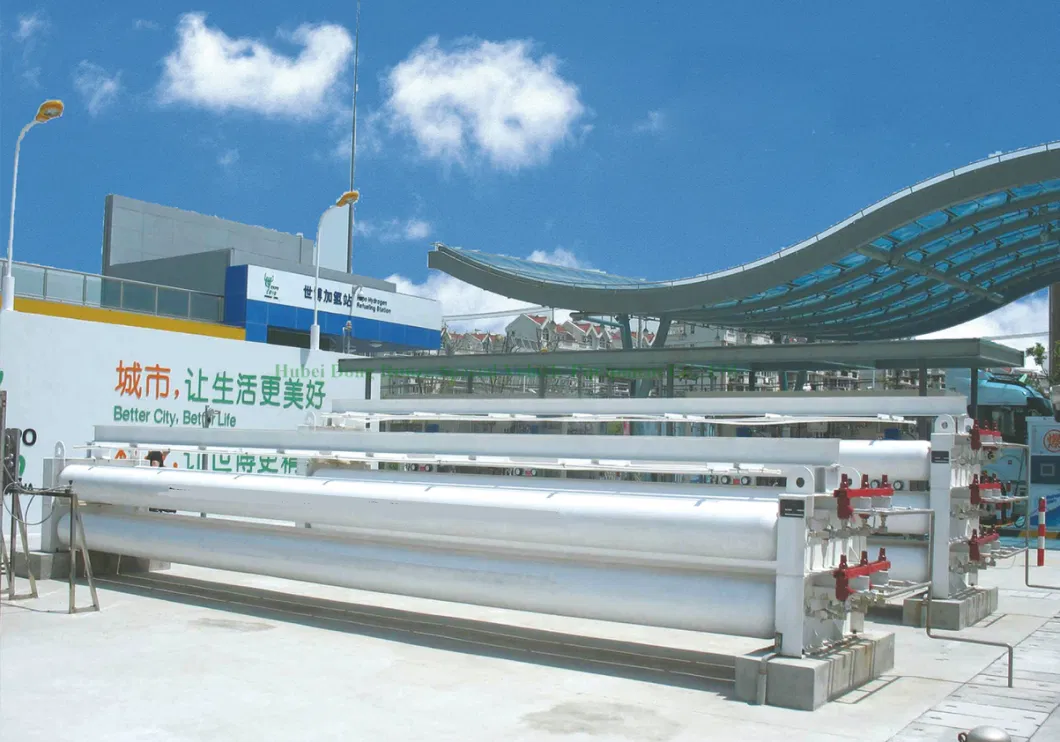

In cascade storage systems for hydrogen storage, as for example athydrogen stations, fuel dispenserA draws hydrogen from tank A, whiledispenser B draws fuel from hydrogen tankB. If dispenser A is over-utilized, tank A will become depleted before tank BHydrogen storage cascade for sale

In cascade storage systems for hydrogen storage, as for example athydrogen stations, fuel dispenserA draws hydrogen from tank A, whiledispenser B draws fuel from hydrogen tankB. If dispenser A is over-utilized, tank A will become depleted before tank BHydrogen storage cascade for sale

Cascade storage system

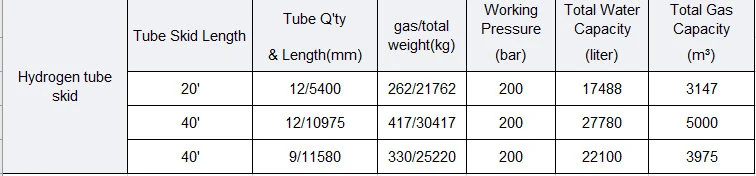

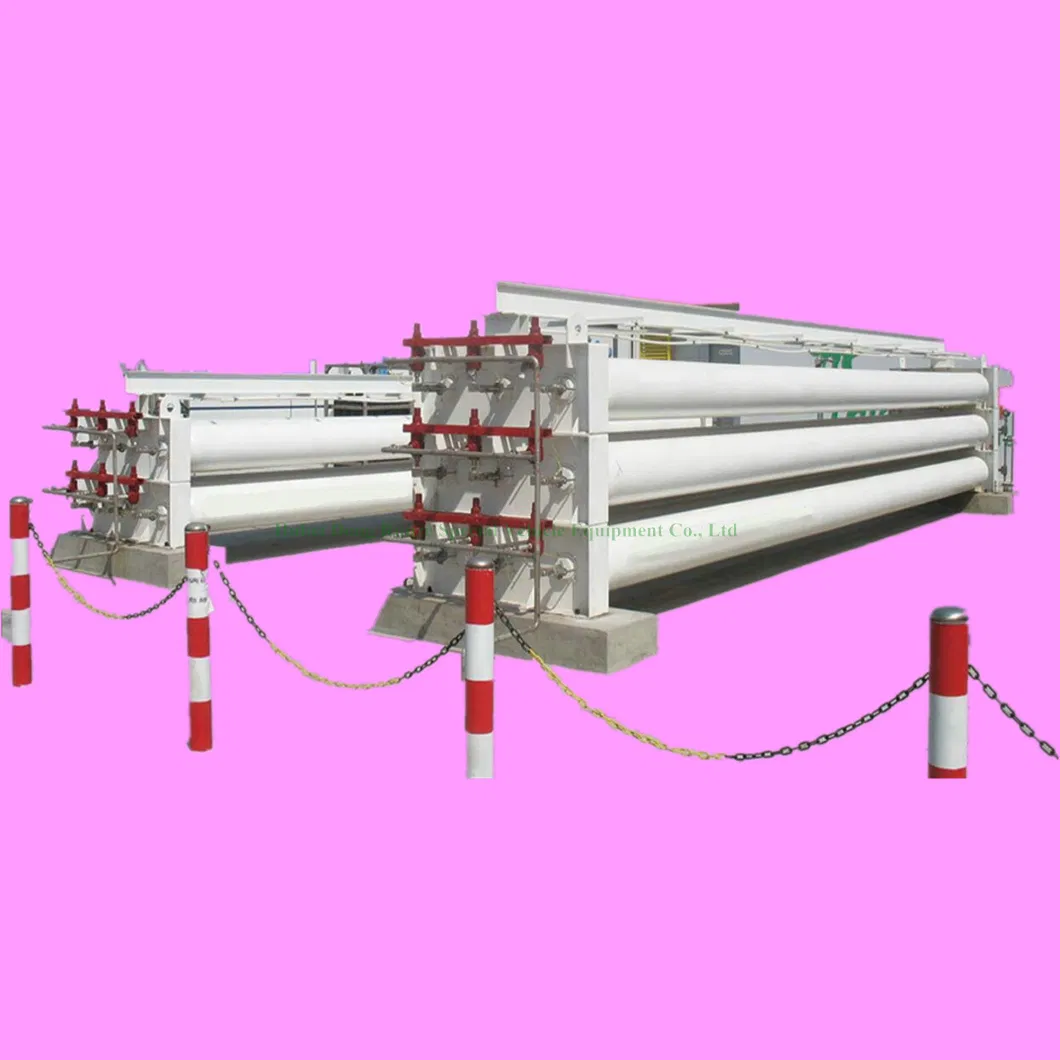

Hydrogen Storage Tank Hydrogen Gas Pressure Vessel Hydrogen Storage Cascade

D

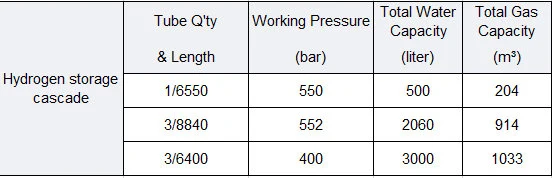

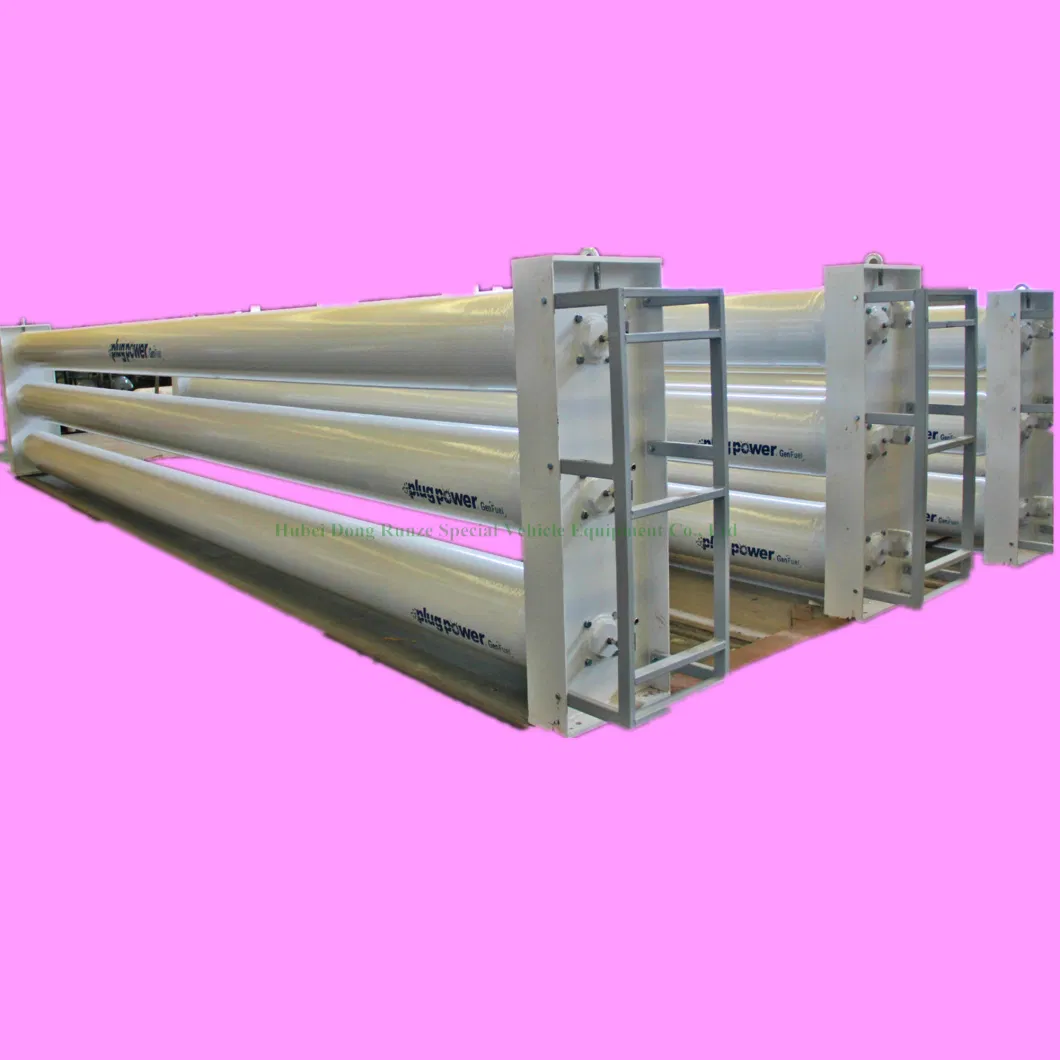

OT ISO Certificated Skid Hydrogen Gas Cylinder Tubes Container

OT ISO Certificated Skid Hydrogen Gas Cylinder Tubes Container

Hydrogen helium Mobile Jumbo Tube Skid gas Storage cascade with high quality and best price

Hydrogen helium Mobile Jumbo Tube Skid gas Storage cascade with high quality and best price

Hydrogen Mobile Hydrogenation Filling Trailer (Hydrogen Tube Station Vehicle )

Application:

Shengrun CNG tube trailer/trailers are widely used in sectors of gas storage, NGV station, CNG tank trailer, and CNG power generating plant and etc. Meanwhile our cylinder skid/trailers are also applied for the storage and transportation of hydrogen, oxygen, nitrogen, argon, helium, purified gas and other kinds of gases.

Features of Dong RunZe high-pressure gas cylinder:

1. Heat-spinning technology;

2. Walking beam continuous heat treatment;

3. Large-size structure and fewer valves, tubes and joints;

4. Concise design, less maintenance on site;

5. Lower weight of design;

6. Additional gas-filling devices.

The unpowered gas station technology, in the parent station, consumes 690 degrees of electricity for every 10000 cubic meters of CNG to 25MPa pressurized (more than 80 degrees of electricity is consumed by about 2000 cubic meters of 20MPa to 25MPa pressurized). It is transported to the sub station by 25MPa cylinder Trailer. With the patented technology of "multi cylinder alternating circulation", the secondary pressurization equipment is no longer needed, and the inflated cylinder can be filled to 20MPa. No noise and pollution emissions, real energy conservation and environmental protection. Compared with the same conditions, for every 10000 cubic meters of CNG sold, the power consumption of secondary pressurization is 1160-690 = 470 degrees. The energy consumption of different compressor models is slightly different

25MPa Intelligent CNG Dispenser Filling Station

Winding Cylinder Trailer, No Need For Secondary Pressure, Save Compression Equipment, Save Power

Skid Mounted Mobile Lng/L- Cng Filling Station With Cng Dispenser Lng Dispenser CNG Tank Trailer

Compact structure,integrated design and less occupied area,convenient for transportation and installation. Adopt high quality sound-proof material, lower working nosies, can meet different environmental requirement from different area. Adopt full air cooling,natural gas and fydraulic oil use the same cooler. Hydraulic cylinder adopts the vertical type; one cylinder can realize two-stage gas compression;oil and gas can be totally separated, and with no oil consumption. 6 Tube CNG Tank Trailer with 25.02m3 Total Cylinder

CNG TUBE CASCADE SKID CONTAINER | ||||||

Model | 9401GGY | |||||

Name | Compressed Nature Gas Long Tube Transportation Semi Trailer | |||||

Brand | DONGRUNZE | |||||

Announcement | 267 Batch | |||||

Volume | 25.02m³ | |||||

Dimension | 13000mm*2480mm*3140mm | |||||

Rated Load | 4340kg | |||||

Tare Weight | 35660kg | |||||

Total Weight | 40000kg | |||||

Vehicle Identification Number | LA99FRG3×××SKW××× | |||||

Usage | The cargo's carrying part is 6 tubes tank-style designed, is suitable for the transportation of compressed natural gas. | |||||

Remarks | Total volume of tank: 25.02m³, Transport medium: CNG, Medium density: 170kg/m³, Tank is composed of 6 tubes. | |||||

UPPER CONSTRUCTION | ||||||

Standard:ISO11120-19999 Q/1500ZTL 002-2012 | ||||||

Tube Skid Container | Items | Parameter | Cylinder | Items | Parameter | |

Type | GSJ08-2210-CNG-25 | Working Pressure | 25MPa | |||

Net Weight(without Chassis) | 26762Kg | |||||

CNG Loading Weight | 4010Kg | Working Temperature | -50~65°C | |||

Rated Weight | 30772Kg | Main material | 4130X | |||

Risk Class | 2.1 | Cylinder Quantity | 6 | |||

UN code | 1049 | |||||

Loading Medium | CNG | Total Cylinder Volume | 25.02m3 | |||

Leakage test pressure | 25MPa | Hydrostatic test pressure | 37.5MPa | |||

Inflating Volume | 6300Nm3(20ºC) | dimension(Diameter x Thickness x Length) | Φ711x17.4x12190 | |||

Heat Treatment | Quenching+ Tempering | Design Temperature | 65ºC | |||

outside dimension | 12192x2438x1400 (mm) | Working Temperature | -40~60°C | |||

Leakage test pressure | 25MPa | |||||

Medium Property | Explosive | |||||

Bursting Disc | Bursting Pressure | 37.5MPa | material | 4130X | ||

Bursting Disc Device Discharging Diameter | ≥ φ20 | material | 4130X | |||

OT ISO Certificated Skid Hydrogen Gas Cylinder Tubes Container

OT ISO Certificated Skid Hydrogen Gas Cylinder Tubes Container