Basic Info.

Model NO.

LNG-80

Delivery Times

90days

Transport Package

40feet Container

Specification

SMC-1500L/H

Trademark

SMC

Origin

China

HS Code

8413810090

Production Capacity

20set Per Year

Product Description

LNG Dispenser LNG CNG Gas Station LPG Coriolis Mass Flow Meter

LNG Dispenser Technical Parameter:

LNG Dispenser Technical Parameter:

Overall Structure

The LNG dispenser consist of a shell, computer controller,display screen, mass flow meter,one-way valve,safety valve, pressure sensor, explosion-proof junction box, LNG connector(liquid nozzle base,liquid nozzle head),stainless steel pipes and other components.

Working Principle

Working Principle

The LNG enters teh dispenser through the transmission pipeline, flows through the mass flow meter, the control valve,the metal hose,the LNG dosing gun, and finally flows into the vacuum bottle of the the filled car. The mass of flow meter measures the physical signals of the density and mass of the liquid flowing through the dispenser, and is converted into an electrical pulse signal by the signal converter and send to the computer controller. The computer automatically calculated the corresponding volume.The amount will be shown to the customers on the display screen to complete a dosing and metering process.

Pipeline Connection

Connect the incoming liquid process pipeline, return gas process pipeline and venting process pipeline as shown in Figure 3-2

Connect the filling pipe, return pipe, filling gun and return air gun of the dispenser as shown in Figure 3-3.

LNG Mass Flow Meter/LNG Plug-in Gun

Patent ID: ZL2012201210130

The patent cancels the "pre-cool" button set by the traditional LNG gas machine, and the operator only needs to insert the plucking gun into liquid port of the car LNG cylinder . Press the "gas" button, the system automatically performs pre-cooling process. After pre-cooling successful, switch to the filling process, no manual operation is required during the process.

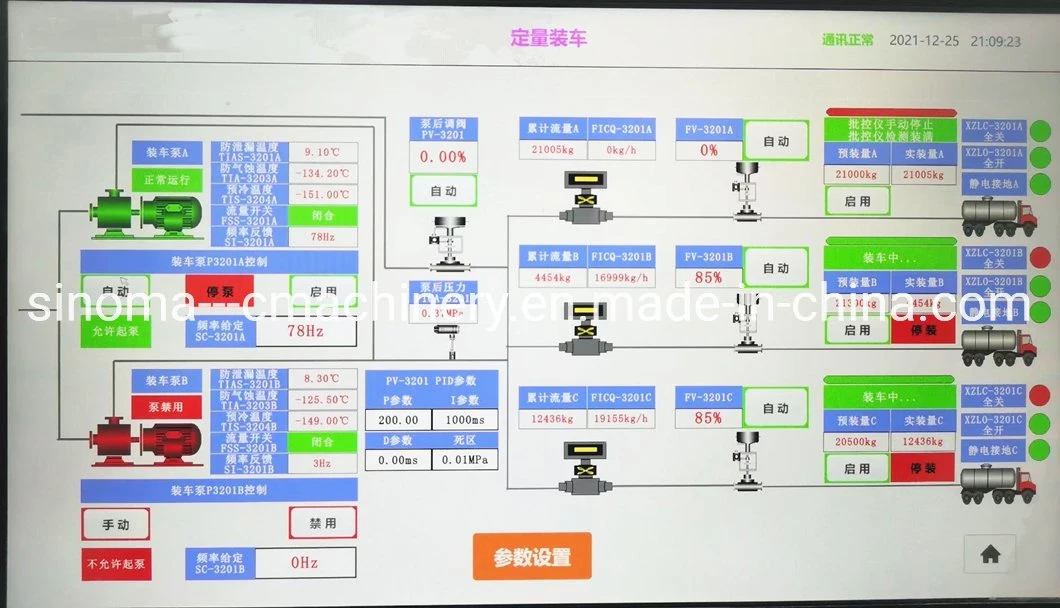

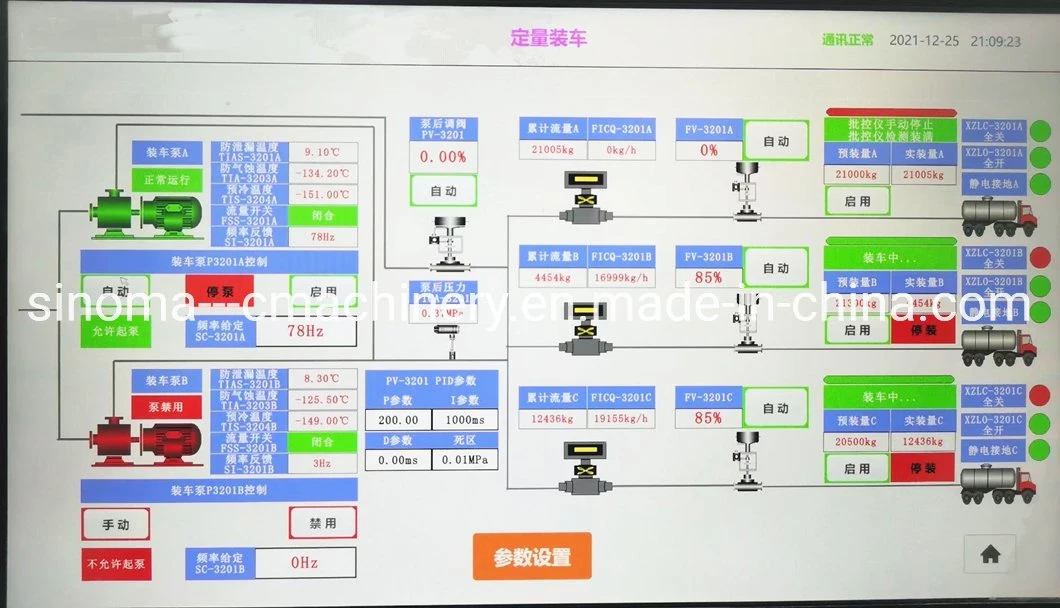

LNG Quantitative Loading System

product description:

The LNG quantitative load system is designed for the demand for the quantitative filling control and information construction of the LNG plant. It adopts smart card technology, automatic control technology, computer and its communication technology to realize the full automation control of the LNG trailer. Safety, efficiency and accuracy of information.

Product main features:

1. Support three pre-quantitative settings (control system remote delivery, password loading; controller local preset loading/IC card input mode);

2. Flow automatic adjustment, quantitative filling control;

3. Multi-safety interlock protection (pressure / temperature / flow overrun, electrostatic ground / lightning protection design, post-discipline)

4. Dynamic monitoring of the production process of loading

5. Data communication function (can enter DCS)

6. ESD function

7. Loading business management and report management

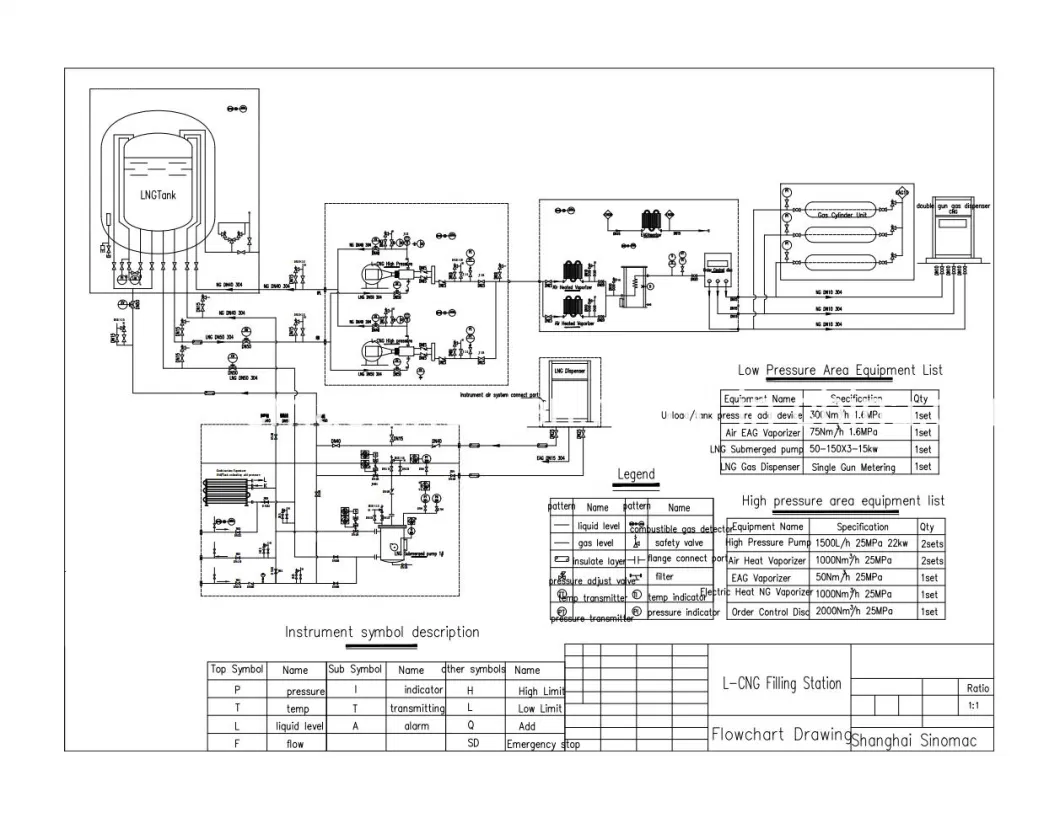

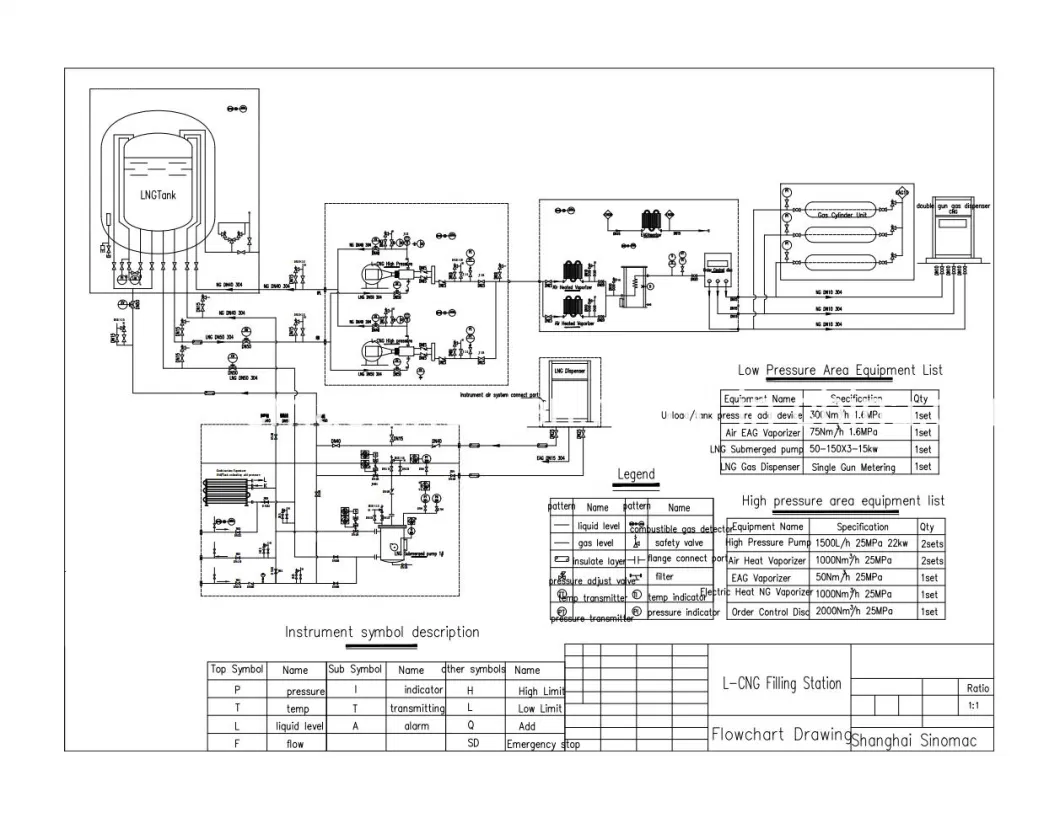

LNG/L-CNG Filling Station Process Flowchart

The General Process Flow Chart is as follows:

LNG/L-CNG Refuel Gas Station Equipment: LNG Dispensing Station Flowchart

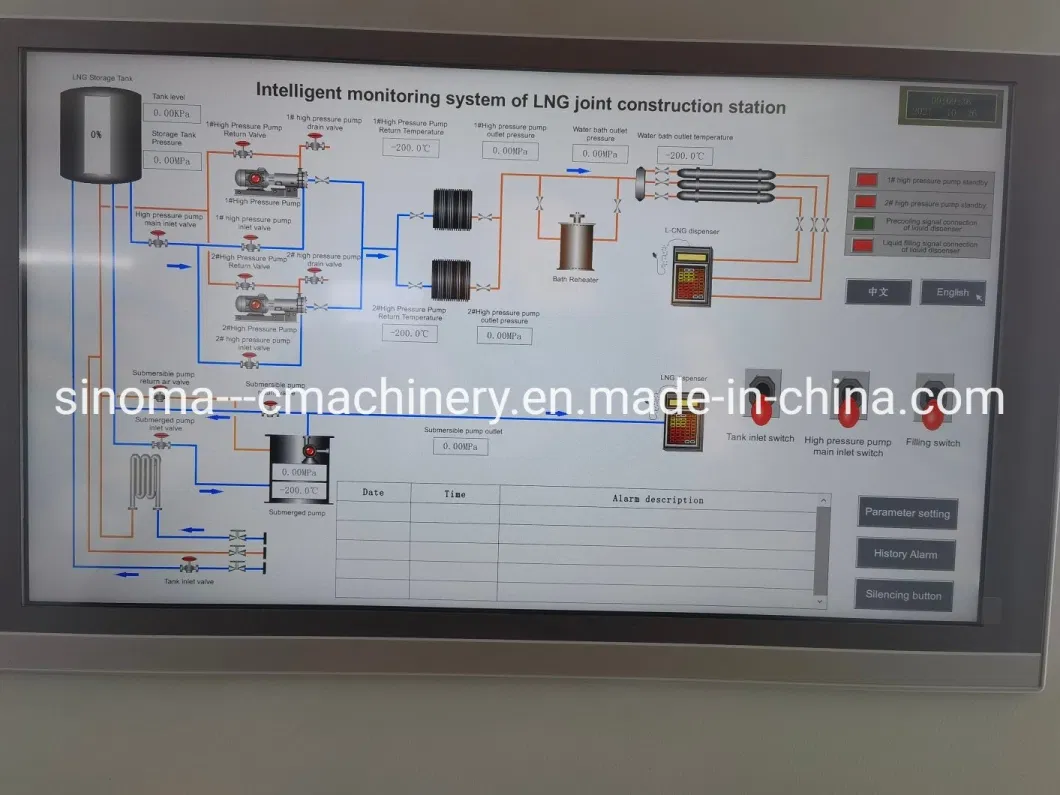

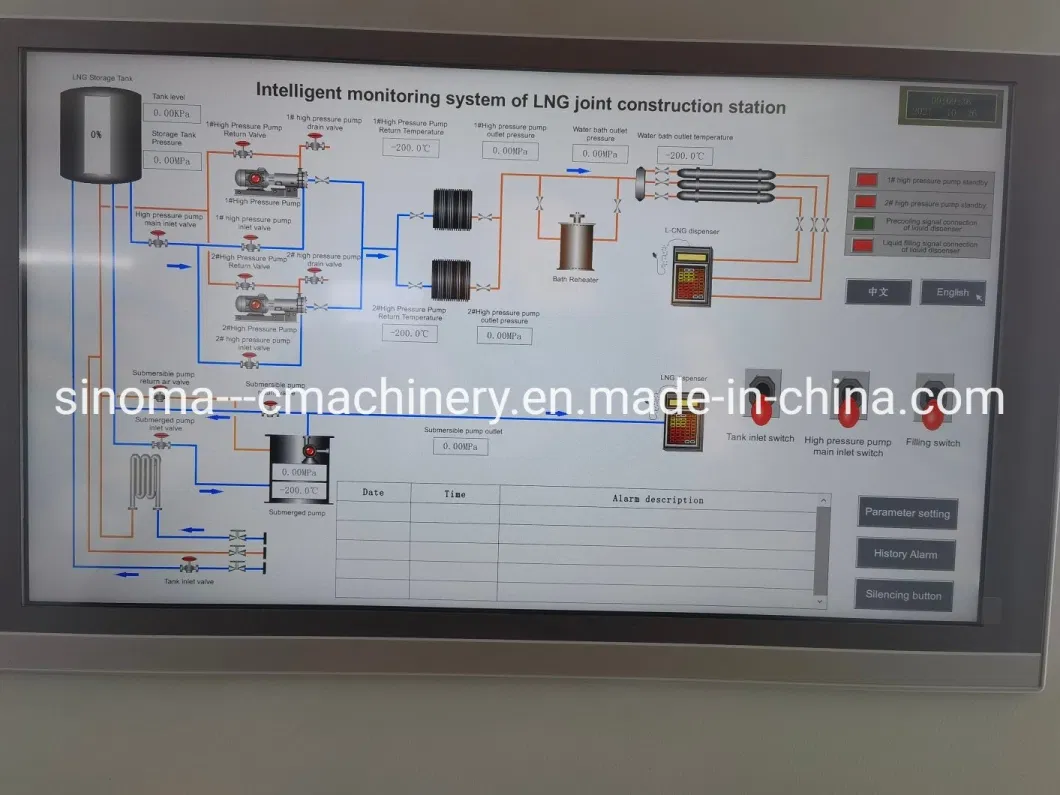

LNG/L-CNG Refuel Gas Station Equipment: LNG Dispensing Station Flowchart  LNG/L-CNG Refuel Gas Station Control System

LNG/L-CNG Refuel Gas Station Control System

LNG/L-CNG Refuel Gas Station Testing:

Welcome all the foreign customers come to visit our factory and LNG/L-CNG Gas Refueling Station Working Site.Thanks.

LNG Dispenser Technical Parameter:

LNG Dispenser Technical Parameter: | Item | Specification |

| Flow Range | 3-80kg/min |

| Max Working Pressure | 1.6MPa |

| Working Temperature | -30-+55ºC |

| Inlet Flow Meter Type | 1" low temp mass flow meter E+H/Emerson |

| Measurement Accuracy | ±1% |

| Minimum Reading Graduation Value | 0.01kg or Nm3,L |

| Single Measurement Range | 0-9999.99kg(or Nm3,L) |

| Cumulative Measurement Range | 0-99999999.99kg(or Nm3,L) |

| Filling Hose | 1" stainless steel soft pipe 4m |

| Return Air Hose | 1/2" stainless steel soft pipe 4m |

| Networking Interface | RS485(use photoelectric isolation 8KV ESD) |

| Electrostatic Discharge Immunity | 4class 8KV |

| Electrical Fast Transient Pulse Group Immunity | 4 class 4KV |

| Surge Immunity | 4 class 4KV |

| Power Supply | AC220V<200W |

| Explosion-proof Grade | ExdibellBT 4Gb |

| Weight | About 325kg |

The LNG dispenser consist of a shell, computer controller,display screen, mass flow meter,one-way valve,safety valve, pressure sensor, explosion-proof junction box, LNG connector(liquid nozzle base,liquid nozzle head),stainless steel pipes and other components.

Working Principle

Working PrincipleThe LNG enters teh dispenser through the transmission pipeline, flows through the mass flow meter, the control valve,the metal hose,the LNG dosing gun, and finally flows into the vacuum bottle of the the filled car. The mass of flow meter measures the physical signals of the density and mass of the liquid flowing through the dispenser, and is converted into an electrical pulse signal by the signal converter and send to the computer controller. The computer automatically calculated the corresponding volume.The amount will be shown to the customers on the display screen to complete a dosing and metering process.

Pipeline Connection

Connect the incoming liquid process pipeline, return gas process pipeline and venting process pipeline as shown in Figure 3-2

Connect the filling pipe, return pipe, filling gun and return air gun of the dispenser as shown in Figure 3-3.

LNG Mass Flow Meter/LNG Plug-in Gun

Patent ID: ZL2012201210130

The patent cancels the "pre-cool" button set by the traditional LNG gas machine, and the operator only needs to insert the plucking gun into liquid port of the car LNG cylinder . Press the "gas" button, the system automatically performs pre-cooling process. After pre-cooling successful, switch to the filling process, no manual operation is required during the process.

LNG Quantitative Loading System

product description:

The LNG quantitative load system is designed for the demand for the quantitative filling control and information construction of the LNG plant. It adopts smart card technology, automatic control technology, computer and its communication technology to realize the full automation control of the LNG trailer. Safety, efficiency and accuracy of information.

Product main features:

1. Support three pre-quantitative settings (control system remote delivery, password loading; controller local preset loading/IC card input mode);

2. Flow automatic adjustment, quantitative filling control;

3. Multi-safety interlock protection (pressure / temperature / flow overrun, electrostatic ground / lightning protection design, post-discipline)

4. Dynamic monitoring of the production process of loading

5. Data communication function (can enter DCS)

6. ESD function

7. Loading business management and report management

LNG/L-CNG Filling Station Process Flowchart

- Unloading Process: Transfer LNG(liquid natural gas) from the tank truck to the LNG storage tank of the gas station through the LNG submersible pump skid(including the unloading truck and the tank booster) at the gas filling station.

- Pressurization Process: After unloading, the LNG is pressurized to above 23Mpa by the LNG high pressure pump skid, and then gasified into CNG(high pressure natural gas)by the high pressure vaporizer skid(including high pressure vaporizer, high pressure water bath electric heating reheater, and sequence control panel), and enter the high pressure gas cylinder group for storage.

- Gas Filling Process: When the pressure in the high pressure gas cylinder group is too low to be able to refill normally, the high pressure pump restarts and vaporizes to replenish and pressurize the high pressure gas cylinder group, and refill the car.

- Liquid Filling Process: LNG is pressurized to about 1.6Mpa by the LNG submersible pump skid, and LNG is filled into the car bottle group through the pipeline and LNG dispenser.

The General Process Flow Chart is as follows:

LNG/L-CNG Refuel Gas Station Equipment: LNG Dispensing Station Flowchart

LNG/L-CNG Refuel Gas Station Equipment: LNG Dispensing Station Flowchart  LNG/L-CNG Refuel Gas Station Control System

LNG/L-CNG Refuel Gas Station Control System LNG/L-CNG Refuel Gas Station Testing:

Welcome all the foreign customers come to visit our factory and LNG/L-CNG Gas Refueling Station Working Site.Thanks.