Basic Info.

Model NO.

YQSJL-YN

HS Code

9026209090

Production Capacity

100 Sets/Year

Product Description

A multiphase flow meter is a device used to measure the individual phase flow rates of constituent phases in a given flow (for example in oil and gas industry) where oil, water and gas mixtures are initially co-mingled together during the oil production processes.

Working Principle:

The main principle of the tri-phase metering system is to effectively separate the free gas from the liquid phase and to measure each phase independently, but with more automation than a conventional seperator. With complete separation, the measurement equipment used in each phase can be utilized to their maximum effectiveness and potential.

Separation of Liquid and Gas, steps involved

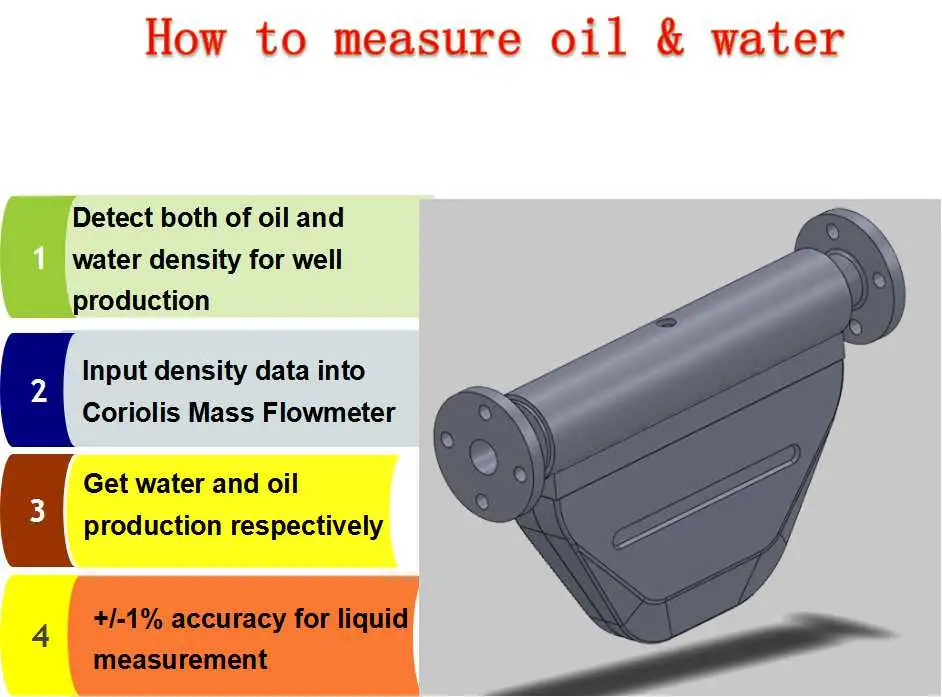

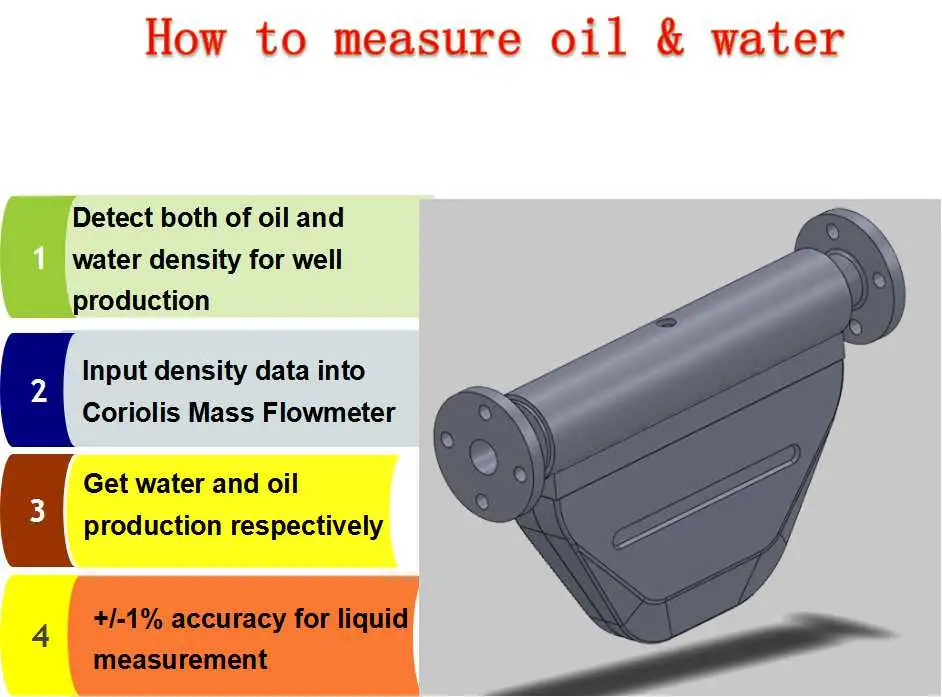

1. Measurement accuracy

Liquid: ≤± 1%

Water : ≤± 3%

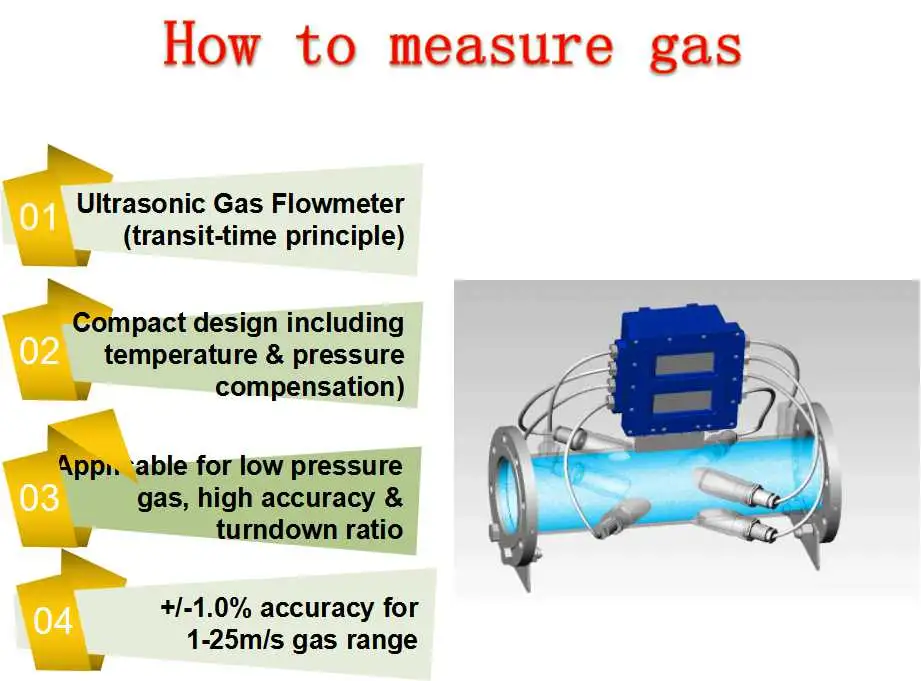

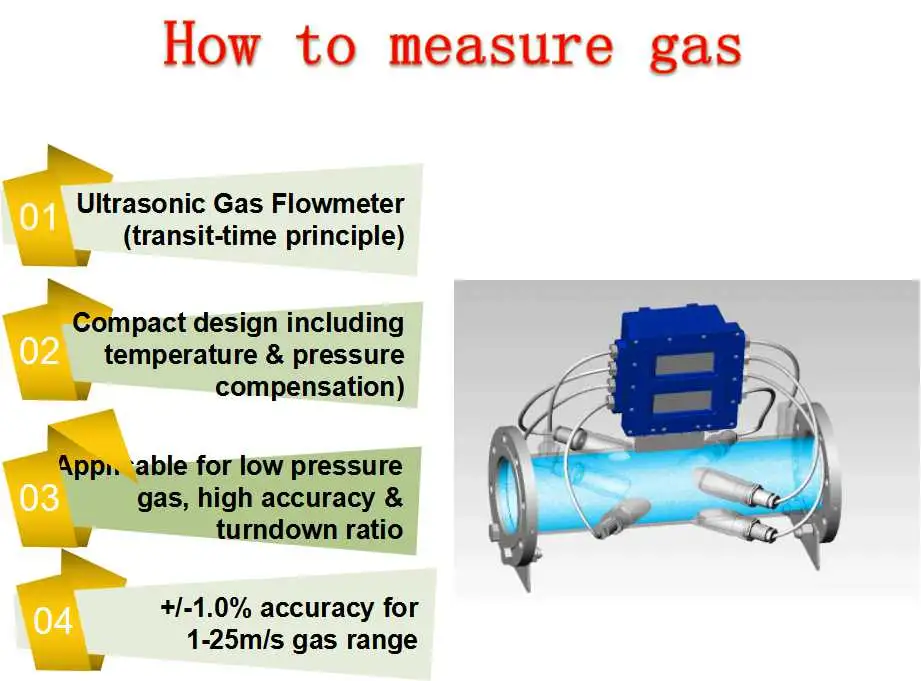

Gas: ≤ ± 1%

2. Capacity range

Liquid: 0-5000 m3/d (0-31450BPD)

Water ratio: 0-100%

Gas: 0-9000m3/d (or customized)

Gas ratio: 0-100%

3. Liquid viscosity: ≤50mPa.s(or customized)

4. Pressure loss: ≤0.1 Mpa

5. Media temperature: 0ºC~100ºC

6. Ambient temperature: -20ºC~55ºC

7. Working pressure: ≤40bar(or customized)

8. Data calculation and display includes instant flow and totalizer for gas, liquid, oil, water

9. Statistical analysis statement and main device online condition can be controlled

10. Remote control and wireless transmission can be optional

Working Principle:

The main principle of the tri-phase metering system is to effectively separate the free gas from the liquid phase and to measure each phase independently, but with more automation than a conventional seperator. With complete separation, the measurement equipment used in each phase can be utilized to their maximum effectiveness and potential.

Separation of Liquid and Gas, steps involved

4 stages of gas separation comprising of:

- Flared tube for pressure drop

- Cyclonic gas separation

- Bubble-hitting gas separation

- Negative pressure burst by pump

Main features of the MPFM are:

- Breaks gas and liquid thoroughly

- High accuracy flowmeters for liquid and gas measurement

- Boost pressure through pumping

- Remote communication to network

- Skid-mounted for easy installation

- Housing option

- Multiple valve option

- Two years full tracking service

1. Measurement accuracy

Liquid: ≤± 1%

Water : ≤± 3%

Gas: ≤ ± 1%

2. Capacity range

Liquid: 0-5000 m3/d (0-31450BPD)

Water ratio: 0-100%

Gas: 0-9000m3/d (or customized)

Gas ratio: 0-100%

3. Liquid viscosity: ≤50mPa.s(or customized)

4. Pressure loss: ≤0.1 Mpa

5. Media temperature: 0ºC~100ºC

6. Ambient temperature: -20ºC~55ºC

7. Working pressure: ≤40bar(or customized)

8. Data calculation and display includes instant flow and totalizer for gas, liquid, oil, water

9. Statistical analysis statement and main device online condition can be controlled

10. Remote control and wireless transmission can be optional