Basic Info.

Product Description

"REACH BOILER" Oil (gas) fired thermal oil boiler is mainly composed of burner, furnace chamber, circulating oil pump, expansion oil tank, chimney and control system. Natural gas, LPG or light diesel fuel is used as fuel, and the open flame is injected in the furnace chamber to heat the thermal oil. In addition, when the normal operation of occasional power outages, oil (gas) heat-conducting oil furnace without the risk of continuous heating coking of the heat-conducting oil.

1. Maximum operating temperature 320 °C.

2. Pipe explosion-proof device.

3. Oil discharge and return temperature display.

4. Isolated electrical control box to extend the service life of electrical appliances.

5. Hot oil BY-PASS pressure relief circuit.

6. Oil pump horsepower and heating power can be customized.

7. Electrical components mainly adopt OMRON, FUJI, TE, LS, SIEMENS, ABB, JUMO.

8. Adopt skid-mounted type module design, easy to install and easy to operate.

9. Using multi-layer coils for heat exchange, the heat receiving area is sufficiently arranged, the surface heat load is low, so that the heat-conducting oil is not easy to coke and accumulate carbon.

10. Fuel in the furnace for adiabatic combustion, can make the combustion fire easier, more fully combustion, better improve the thermal efficiency of the boiler.

Model:YY(Q)W Type Gas/Oil Fired Thermal oil Boiler

Structure:Oil Tube Three Pass

Rated Steam Capacity:0.10-20 ton/hr

Rated Steam Pressure:1.0Mpa

Rated Steam Temperature:320°C

Application:Textile Mill,Food and Beverage,Chemical,Medicine,Light Industry,Rubber,Printing and Dyeing Plant,Paper Mill,Wood Processing,Garment and Laundry etc.

| Model No. | YY(Q)W-120Y(Q) | YY(Q)W-240Y(Q) | YY(Q)W-350Y(Q) | YY(Q)W-500Y(Q) | YY(Q)W-700Y(Q) | YY(Q)W-1000Y(Q) | YY(Q)W-1200Y(Q) | YY(Q)W-1400Y(Q) |

| Rated thermal power (kw) | 120 | 240 | 350 | 500 | 700 | 1000 | 1200 | 1400 |

| Medium outlet temperature (ºC) | ≤350°C | |||||||

| Applicable fuel | Natural gas/LPG/CNG/Diesel Oil/Heavy Oil/Waste Oil | |||||||

| Efficiency | ≥95% | |||||||

| Diesel Consumption (Kg/h) | 12 | 25 | 37 | 52 | 69 | 100 | 120 | 140 |

| Natural Gas (Nm³/h) | 15 | 30 | 44 | 63 | 83 | 120 | 145 | 170 |

| Expansion tank volume(M3) | 0.5 | 0.5 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2.5 |

| Oil storage tank volume (M3) | 1 | 1 | 2.5 | 2.5 | 2.5 | 4 | 4 | 5 |

| Weight (t) | 1.5 | 2 | 2.6 | 3 | 3.7 | 5 | 5.8 | 6.7 |

| Overall dimensions (L*W*D(mm)) | 1650*1050*1520 | 1900*1200*1900 | 2150*1400*2050 | 2200*1400*2050 | 3250*1450*2250 | 3350*1650*2450 | 3800*1750*2600 | 4150*1900*2800 |

| Model No. | YY(Q)W-1800Y(Q) | YY(Q)W-2100Y(Q) | YY(Q)W-2400Y(Q) | YY(Q)W-3000Y(Q) | YY(Q)W-3500Y(Q) | YY(Q)W-47000Y(Q) | YY(Q)W-6000Y(Q) | YY(Q)W-7000Y(Q) |

| Rated thermal power (kw) | 1800 | 2100 | 2400 | 3000 | 3500 | 4700 | 6000 | 7000 |

| Medium outlet temperature (ºC) | ≤350°C | |||||||

| Applicable fuel | Natural gas/LPG/CNG/Diesel Oil/Heavy Oil/Waste Oil | |||||||

| Efficiency | ≥95% | |||||||

| Diesel Consumption (Kg/h) | 180 | 210 | 244 | 300 | 350 | 470 | 580 | 680 |

| Natural Gas (Nm³/h) | 220 | 260 | 290 | 365 | 425 | 570 | 705 | 780 |

| Expansion tank volume(M3) | 2.5 | 2.5 | 3 | 3 | 3 | 5 | 5 | 6 |

| Oil storage tank volume (M3) | 5 | 5 | 8 | 8 | 8 | 10 | 10 | 15 |

| Weight (t) | 7.8 | 8.8 | 9.8 | 15.5 | 17.8 | 21.5 | 25 | 27.5 |

| Overall dimensions (L*W*D(mm)) | 4600*2000*3050 | 5000*2050*3100 | 5000*2250*3100 | 6000*2400*3400 | 6550*2500*3600 | 7300*2600*3700 | 7800*3050*3800 | 8200*3050*3800 |

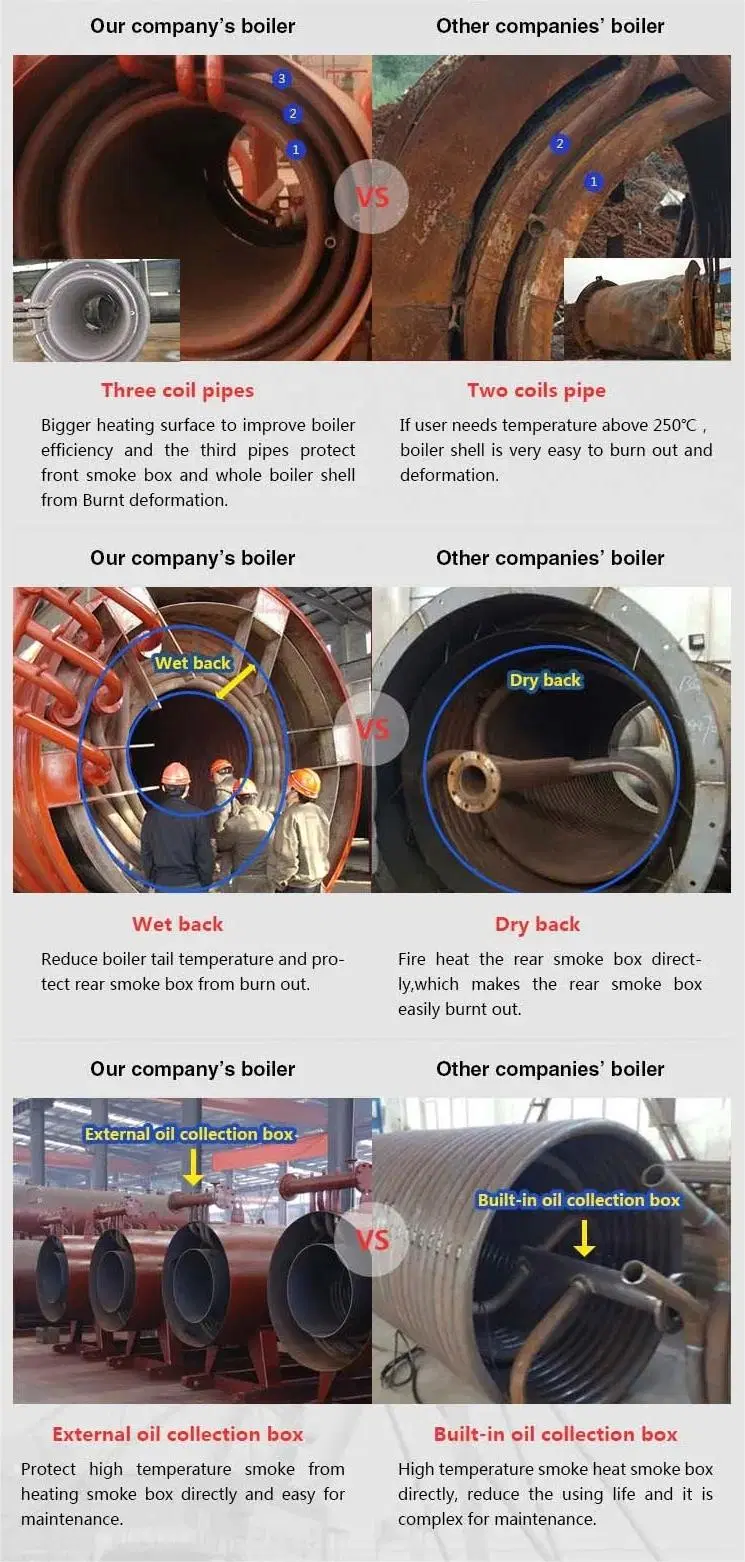

Technical Advantages

Safety

Environmental protection

Combustion chamber uses full membrane water cooling wall structure and pressurized combustion without smoke mixture.

Energy conservation

Good quality alumina silicate fiber and fire clay insulation material are used and the boiler body temperature is controlled below 45ºC and greatly heat loss is reduced. Combustion chamber is designed with narrow distance tube membrane water cooling wall which has good air proof to reduce heat lost and increase boiler thermal efficiency. Internal inspection holes uses high-alumina refractory and manhole cover seal devices, solving superheat problem in this part caused by using refractory bricks.

Convenience

Manholes are placed on the front and back side of drums and inspection doors on back side of boiler easy to open for inspection and clean inner and outer parts.

Longer lifespan

Membrane structure are used in the front and back wall for boiler body and highly increased their lifespan to over 20 years.

The key processes including material cutting, rolling, drilling are done by advanced CNC machining process to reduce the assembly stress and extend boiler service lifetime.

Flutter prevention fastener is used for high temperature part convection tubes, which avoid convection tube cracking problem.

Longitudinal and girth joint adopt advanced automatic submerged-arc welding for good welding quality. All longitudinal and girth joint will be tested by radiographic inspection.

Q1: How to install a boiler?

A1: Reach Boiler provides completed installation drawing and operation manual, or can send engineer to your site for guiding and trainning.

Q2: How many years is the boiler's life span

A2: The boiler is designed for at least 10 years life span, but under good maintenance, usually the boiler can use at least 15 years, Reach Boiler provide full life after-sales service to each sold boiler.

Q3: How to choose a boiler model?

A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, Yineng Boiler will suggest a suitable model based on your usage.

Q4: How is the warranty term?

A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client's side, the Seller will help supply the spare part at lowest cost.