Basic Info.

Product Description

Pressure Reduction Station

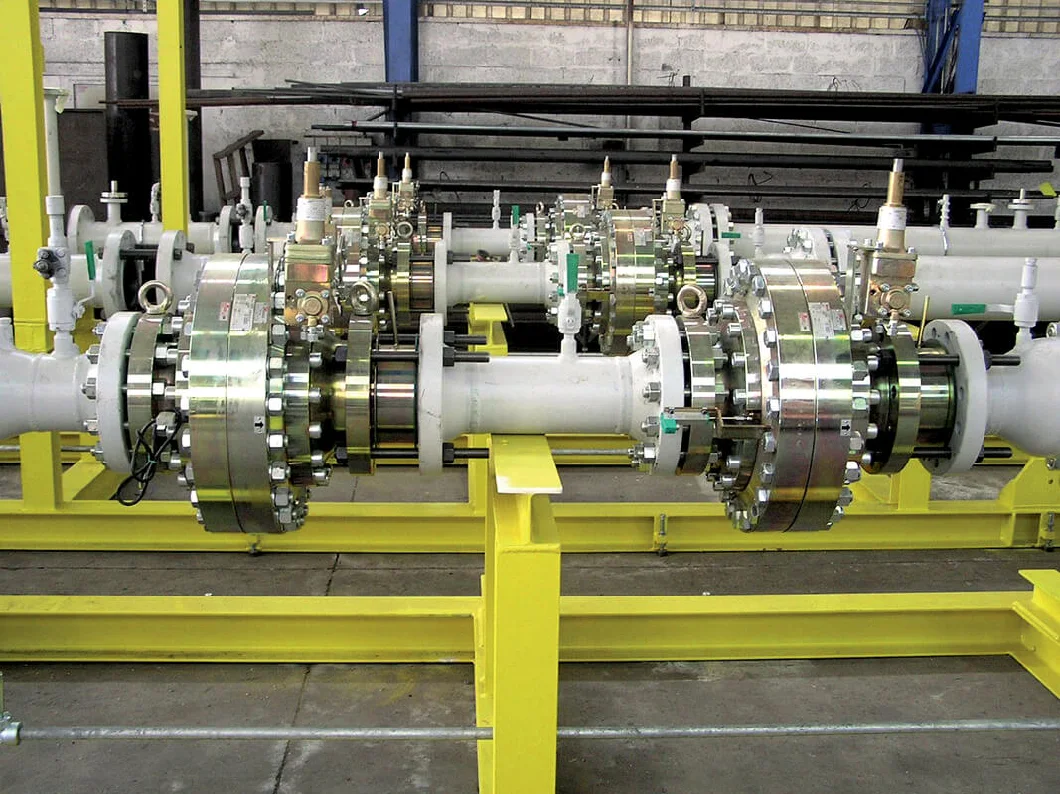

Pressure reduction and metering system is used to stabilize the outlet pressure under the condition that the inlet pressure and downstream flow are constantly changing. Structure : inlet and outlet valves, inlet filters, safety shut-off valves, monitoring pressure regulators, and working pressure regulators.

Pressure Reduction Station is used for separating of particles, pressure regulating and metering of feed gas received in the station.

PRMS for LNG plants

Pegoraro Gas Technologies designed and realized a gas pressure filtering, reducing and metering station powered by LNG treatment plant: this solution is one of the first installation in Italy.

LNG treatment plant is composed by a cryogenic tank with capacity of 100 cubic meters at -160°C and an atmospheric heat exchangers system.

The plant is supplied and filled weekly by a trailer loaded with LNG coming directly from Spain.

The fluid is stored into the cryogenic tank: through the atmospheric heat exchangers system, the gas passes naturally from LNG liquid state to gaseous state, ready to be injected into the gas network.

The pressure of the gas at the gaseous state coming from LNG treatment plant is reduced by our station.

The end-user monitors all the parameters (flow, pressure, measure, heating) by PLC.

Product Details of Pressure Reduction Station

Overview

Pressure Reduction Station is used for separating of particles, pressure regulating and metering of feed gas received in the station. Specification

1. | Structure | Skid |

2. | Regulating level | Two |

3. | Design temperature | -40 to 60°C |

4. | Medium | CNG |

5. | Inlet pressure | 25 MPa |

6. | Outlet pressure | 0.6 MPa |

7. | Max working pressure | 25 MPa |

8. | Design pressure | 25 Mpa |

9. | NG outlet temperature | ≥10ºC |

10. | Entrance diameter | DN25 |

11. | Export diameter | DN80 |

12. | Safety device | Overpressure discharge, high altitude release device, gas leakage alarm, overpressure automatic emergency cut off. |

13. | Flowrate | 1000Nm3/h |

14. | Working time | Intermittent operation,or 24h continuous operation

|