- Overview

- Product Description

- Company Profile

Basic Info.

Product Description

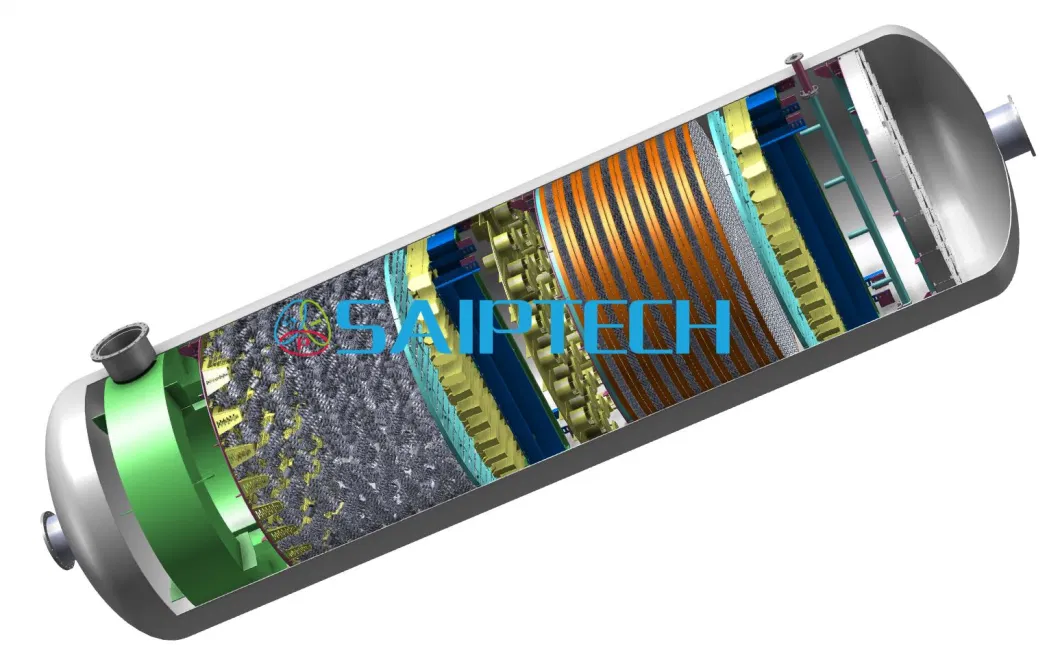

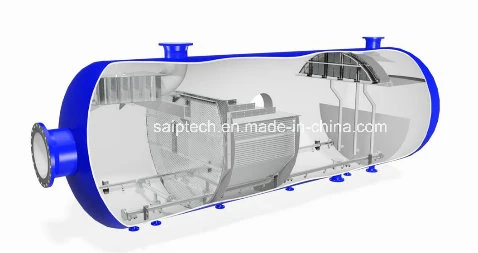

Saiptech's Separation Equipment

Through the years, Saiptech has become firmly established as the top supplier of a comprehensive range of removable separator internals to the oil & gas industries throughout China and overseas. Our top-notch products and services have gained a reputation for robust design, reliable & proven performance and efficient technical support.

The Portfolio of Separator Internals

| Inlet Devices | Distributors | Coalescers | Mist Eliminators | Others |

| Deflectors | Perforated Baffles | Plate Packs | Wire Mesh | Desalter Grids |

| Bifurcators | Slotted Baffles | Corrugated Packs | Vane Packs | Sand Jets |

| Multi-Vane | Pipe Distributors | Matrix Packs | Axial Cyclones | Vortex Breakers |

| Cyclone Defoamers | Wave Breakers | Mesh Coalescers | Multicyclones | Anti-Motion FPSO |

The comprehensive service from Saiptech

which can be tailored to your project requirements, including:

• process design

• feasibility studies

• detailed engineering

• equipment manufacture and supply

• installation

• trouble shooting

• de-bottlenecking

• revamp & capacity expansion

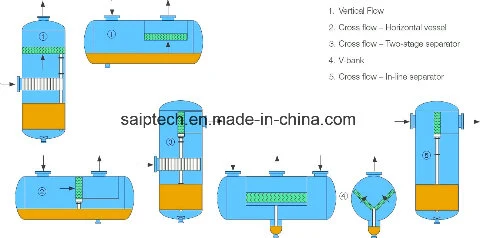

Applications

• Test Separators

• Production Separators

• Electrostatic Treaters

• Liquid/Liquid Coalescers

• Slug Catchers

• Cyclone Separators

• KO & FWKO Drums

• Flare Drums

• Compressor Scrubbers

• Pipeline Scrubbers

• Inlet Distributors

• Sand Removal Systems

Saiptech welcome the opportunity to assist our customers, including end users, EPC contractors and vessel fabricators, to select and customize from our standard range of separation internals to provide an optimized solution for any specific process and vessel configuration.

In an increasingly competitive business environment, we have developed a unique approach to providing added value and benefit to our customers by focusing on quality engineering rather than high volume manufacturing. our vessel internals, including distillation and absorption as well as separation equipment function as the vital organs of a process plant. Therefore, well engineered equipment is not only the key to long term profitability but intelligently engineered vessel internals may often result in lower overall capital costs.

For many years, Saiptech has been a leader in engineering for mass transfer, phase separation, and reactor internals. Our innovative technology and patented high-performance products cater to a diverse clientele in industries such as petroleum, petrochemical, chemical, and environmental protection. We specialize in processes like distillation, rectification, absorption, desorption, and multiple phase separation.

Our commitment to continuous research and development, coupled with extensive engineering experience, enables us to provide comprehensive solutions to our clients. Our services encompass process simulation and optimization, de-bottlenecking, hydraulic calculation and analysis, field troubleshooting, CFD modeling, and on-site services. In our modern fabrication shop, we manufacture various equipment and components, including distillation trays, column packing, internals, and reactor internals.

We take pride in our professional and experienced staff, known for their expertise in technology, process design, equipment design, manufacturing, system integration, plant design, modifications, project management, and process consultancy. The Saiptech team, composed of seasoned chemical and mechanical engineers, consistently delivers design packages that surpass client expectations.

As a privately owned and operated company, Saiptech adheres to the core belief that clients come first. This principle has shaped our business model, emphasizing professionalism, trust, and a commitment to excellence. Our mantra of "Clients first" guides us in all our endeavors, ensuring a dedicated approach to serving the needs and achieving the goals of our valued clients.