- Overview

- Company Profile

- Product Description

- Product Parameters

- Detailed Photos

- Features and Benefits

- Project Performance

- FAQ

Basic Info.

Product Description

Sichuan GreenFir Machinery Equipment Co., founded by a group of qualified and experienced executive managers and engineers with the objective of providing equipment and services(process design, detail engineering, construction management, procurement and technical inspection) to the clients in a large number natural gas projects. The main products includes LNG plant, natural gas dehydration equipment, natural gas sweetening equipment, LPG plant, C2+ product recovery equipment, demethanizer, deethanizer, etc.

The company has obtained a number of industry certitications, such as ASME, special equipment production license, pressure vessel design and manufacturing license, etc. GreenFir has two manufacturing based in Chengdu City and Ziyang City, with a manufacturing workshop area of 35000 square meters

Technical capabilities and products

Technical capabilities and products

1. Natural gas deacidification (desulfurization and decarbonization) technology

· Treating capacity: 1000~500000Nm3/h

· Operation pressure: 0.5~15MPa

· Purification index: H2S<4ppm, CO2<50ppm

2. Natural gas dehydration technology

√ Triethylene glycol dehydration

· Treating capacity: 1000~500000Nm3/h

· Operation pressure: 0.5~15MPa

· Product gas water content: <7lb/MMSCF

· Glycol loss: ≤13.4L/104Nm3

√ Molecular sieve dehydration

· Treating capacity: 1000~500000Nm3/h

· Operation pressure: 0.5~15MPa

· Dehydration depth: 1ppm

3. Ethane recovery technology

· Treating capacity: 1000~500000Nm3/h

· Operation pressure: 0.5~15MPa

· According to different conditions and requirements, gas supercooling process, liquid supercooling process, and partial dry gas circulation process can be used for recovery

· Ethane recovery rate can reach more than 95%

4. Natural gas liquefaction technology

· Treating capacity: 30,000~2,000,000Nm3/day

· Product specification:

H2S<4ppmv

CO2<50ppmv

Water content <1ppmv

C5+<0.1 mol%

· Single stage or mixed refrigerant process with precooling

5. LNG regasification technology

· Bottle group gasification station, standard gasification station, integrated gasification station

· The gas supply is flexible and fast, and can enter dense areas for gas supply

· High equipment integration, small footprint

· Easy to carry and install

· Safe and reliable

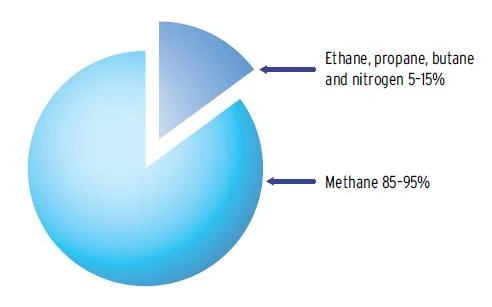

What is LNG?

Liquefied natural gas is gas that has been cooled to -260°F (-160°C) and converts to a liquid state. When natural gas is in a liquid form, it takes up approximately 1/600th of the space it would as a vapor, making transportation much more efficient and economical.

LNG is mostly methane plus a small percent of ethane, propane and butane, and trace amounts of nitrogen.  How is natural gas liquefied?

How is natural gas liquefied?

Natural gas is converted to a liquid in a liquefaction plant, or "train". An LNG train performs three main processes:

Dust and slug (water and condensate) is removed along with hydrogen sulfide (H2S) and mercury (Hg). These pollutants can cause corrosion and freezing problems, especially in aluminum heat exchangers.

2. Acid Gas Removal and Dehydration

Carbon dioxide (CO2) is absorbed and removed from natural gas with an amine absorber (acid gas removal or AGR) and an adsorbent is used to remove water. These impure substances are removed so that ice will not form during the subsequent liquefaction process.

3. Heavy Hydrocarbon Separation and Liquefaction

Heavy hydrocarbons (C5+) are removed by fractionation before liquefaction.

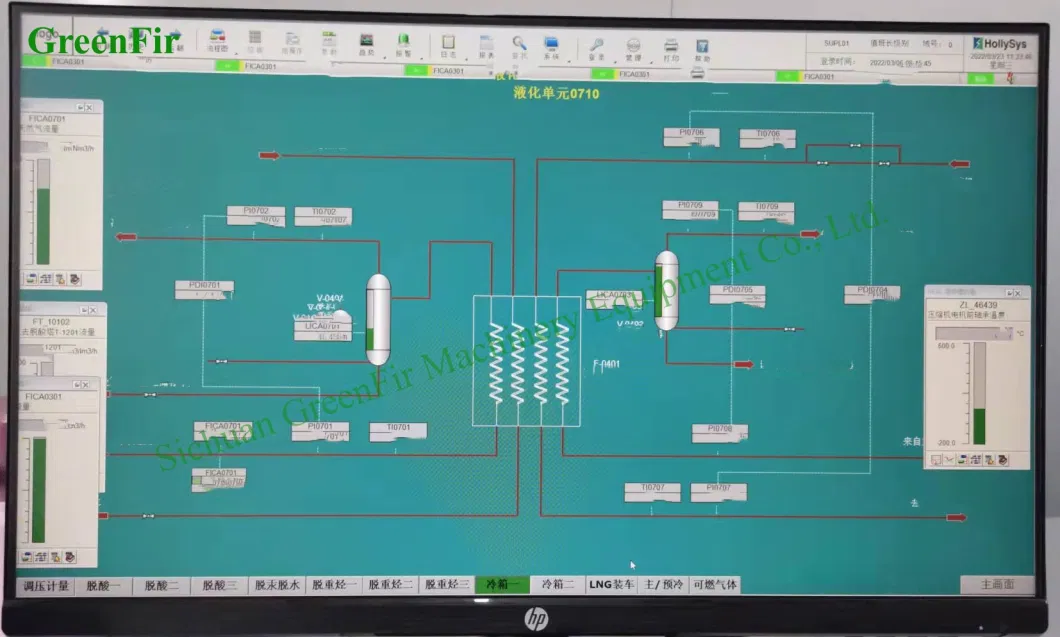

The main system of whole set of LNG plant:

1. Natural gas filtering, metering and pressure regulation system

2. Natural gas purification system(acid gas removal unit, dehydration unit, mercury removal unit)

3. Natural gas liquefaction system(cold box, MR compressor, etc.)

4. LNG storage system

5. LNG loading system

6. Instrument control system(DCS, SIS, FGS, etc.)

7. Electrical control system

8. Utilities(instrument air and PSA nitrogen system, desalted water system, heat transfer oil system, flare gas system)

9. Feed gas booster compressors(Optional)

10. Heavy hydrocarbon removal system(Optional)

11. Nitrogen removal system(Optional)

12. Power generators(Optional)

GreenFir owns a variety of self-developed natural gas liquefaction technologies, such as mixed refrigerant cycle (MRC) and N2 cycle. And GreenFir develops optimized single-stage mixed refrigeration (SMR), C3 pre-cooled mixed refrigeration (C3MR) and double mixed refrigeration (DMR) considering different cooling principles and working conditions. LNG plants are typically sized to produce from 20 to 1440 tons per day of LNG.

| Design scale | 30,000Nm3/d | 50,000Nm3/h | 100,000Nm3/d | 200,000Nm3/d | 300,000Nm3/d | 500,000Nm3/d | 1,000,000Nm3/d | 2,000,000Nm3/d |

| 1.1MMSCFD | 1.9MMSCFD | 3.8MMSCFD | 7.6MMSCFD | 11MMSCFD | 19MMSCFD | 38MMSCFD | 76MMSCFD | |

| Acid gas removal method | MDEA | |||||||

| Design life | 20 years | |||||||

| Operation flexibility | 50~110% | 50~110% | 50~110% | 50~110% | 85~105% | 85~105% | 85~105% | 85~105% |

| Continuous running time | 8000 hours | |||||||

Dehydration, mercury removal skid and acid gas removal skid

Natural gas liquefaction skid

LNG loading skid DCS control system

LNG tanker or LNG storage tanks by loading arms. supervision, control for the whole plant.

Note: All skids are customized according to the actual gas condition. The above are part of the key equipment. For more details please contact us.

1. Shorter project period1.1 24 weeks project period: 16 weeks for all processes from contract signing to product FOB delivery and 8 weeks from equipment installation to LNG production upon the complete of civil work, ensuring 60% project time reduction.

2. Higher economic return

2.1 5 month earlier for economic returns when compared with conventional LNG projects.

2.2 Bulk purchasing ensures lower product price.

2.3 Skid-mounted module ensures a lower onsite cost.

3. More flexible and scalable

3.1 Flexible for different kinds of feed gas including CBM, shale gas, associated gas, pipeline gas, flare gas, peak-shaving and biogas etc.

3.2 Scalable for combinable and expandable solution to meet requirements for project upgrading.

4. Intelligent remote control

4.1 Remote monitoring, real-time data acquisition by mobile phones, iPad and other terminals.

4.2 Independent FGS system for fire and gas alarm system and running control system.

5. Better services

5.1 Customer-focused services to supply professional and reliable follow-up inspection, fault handling and training services.

| No. | Project Name | Location | Qty | Year | |

| 1 | 300,000Nm3/d LNG re-liquefaction plant | China | 1 | 2016.10 | |

| 2 | 50,000Nm3/d wellhead gas recovery project | China | 1 | 2016.11 | |

| 3 | 30,000Nm3/d wellhead gas recovery project | China | 1 | 2017.5 | |

| 4 | 30,000Nm3/d mini LNG plant | China | 2 | 2018.6 | |

| 5 | 300,000Nm3/d heavy hydrocarbon removal skid | China | 1 | 2019.4 | |

| 6 | 600,000Nm3/d mini LNG plant | China | 1 | 2020.1 | |

| 7 | Natural gas demethanizer column and deethanizer column | Kazakhstan | 1 | 2020.7 | |

| 8 | 100,000Nm3/d mini LNG plant | China | 2 | 2021.1 | |

| 9 | 3.5MMSCFD and 50TPD LNG plant | Iran | 2 | 2021.4 | |

| 10 | Heavy hydrocarbon removal system of 100,000Nm3/d LNG plant | China | 1 | 2021.6 | |

| 11 | Heavy hydrocarbon removal system of 60,000Nm3/d LNG plant | China | 1 | 2021.9 | |

| 12 | 50,000Nm3/d mini LNG plant | China | 1 | 2021.10 | |

| 13 | 100,000Nm3/d mini LNG plant | China | 2 | 2021.12 | |

| 14 | 17.88MMSCFD ethylene compressor station | Iran | 1 | 2022.4 | |

| 15 | 220,000Nm3/d mini LNG plant | China | 1 | 2022.8 | |

| 16 | 300,000Nm3/d mini LNG plant | China | 1 | 2022.12 | |

| 17 | 300,000Nm3/d flare gas recovery plant | Iran | 1 | 2022.12 | |

| 18 | 200,000Nm3/d amine sweetening package project | Iran | 1 | 2022.12 | |

| 19 | Deethanizer rectification system | Kazakhstan | 1 | 2023.3 |

1. Are you manufacturer or trading company?

We are professional manufacturer of multi-components gas purification, separation and liquefaction equipment.

2. What's your advantage?

We provide you not only technology-leading, stable and reliable, cost-efficient equipment, but also solutions and after-sales services.

3. Have your engineers participated in any foreign projects?

Yes, our engineers have more than 20 years experience in our field and have participated in the design, manufacturing, installation and commissioning of the equipment in Turkey, Iran, Egypt, Nigeria, Russia, India, etc.

4. How can I get the exact price of the product?

Please tell us your specific requirements, so we can provide the most suitable products and solutions to you.