Basic Info.

Model NO.

Velcon I-638C5TB

Trademark

Lifeierte

Origin

China

HS Code

8421999090

Production Capacity

50000PCS/Month

Product Description

Introduction

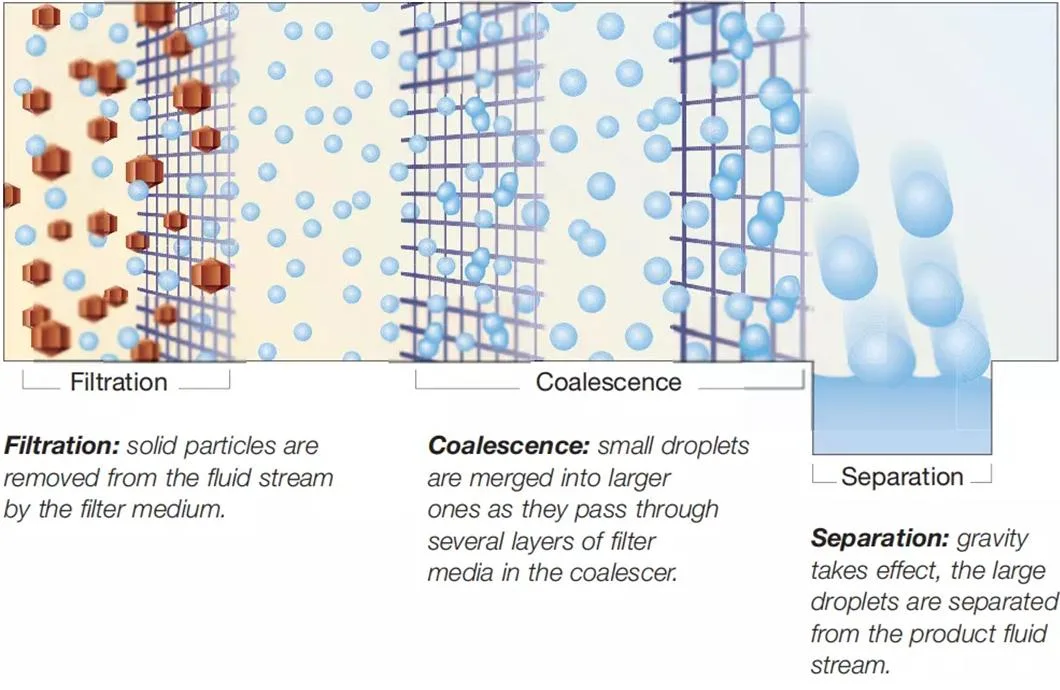

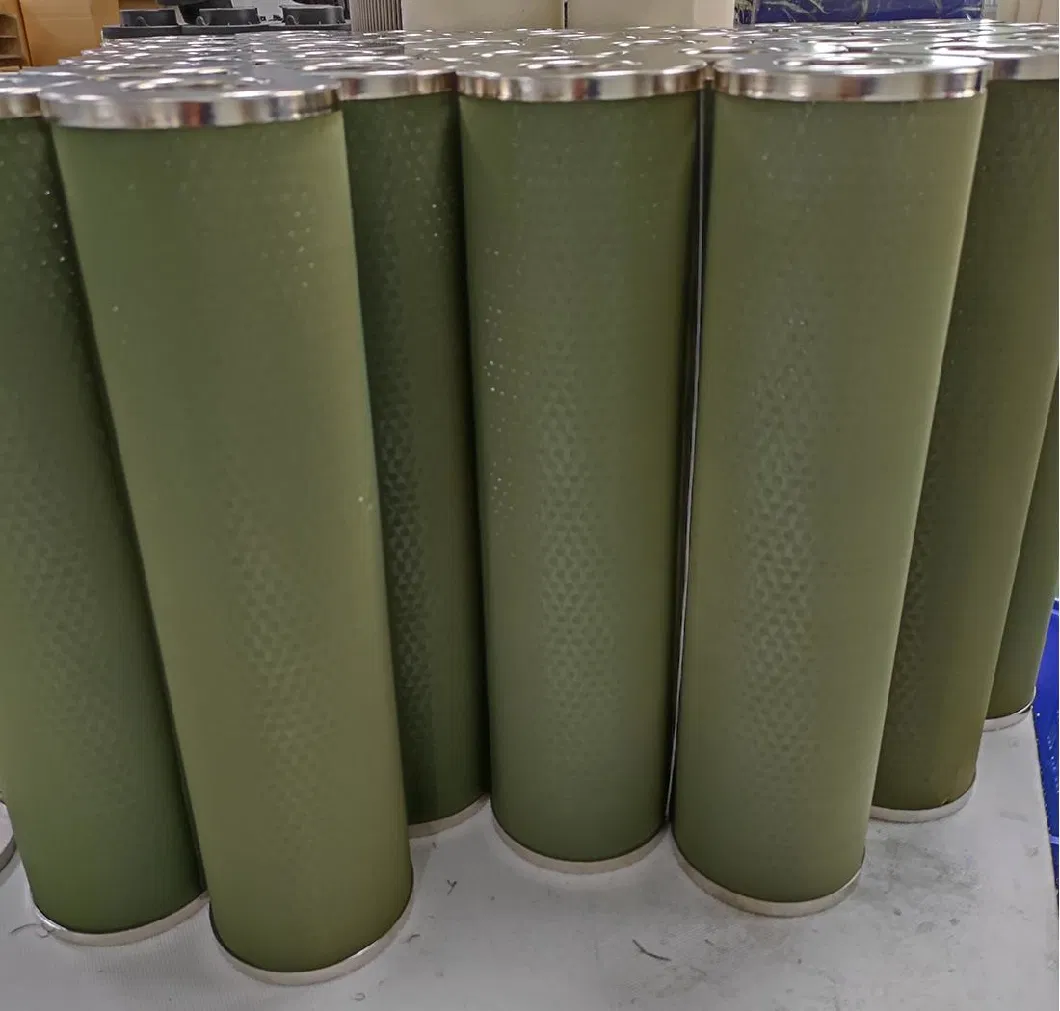

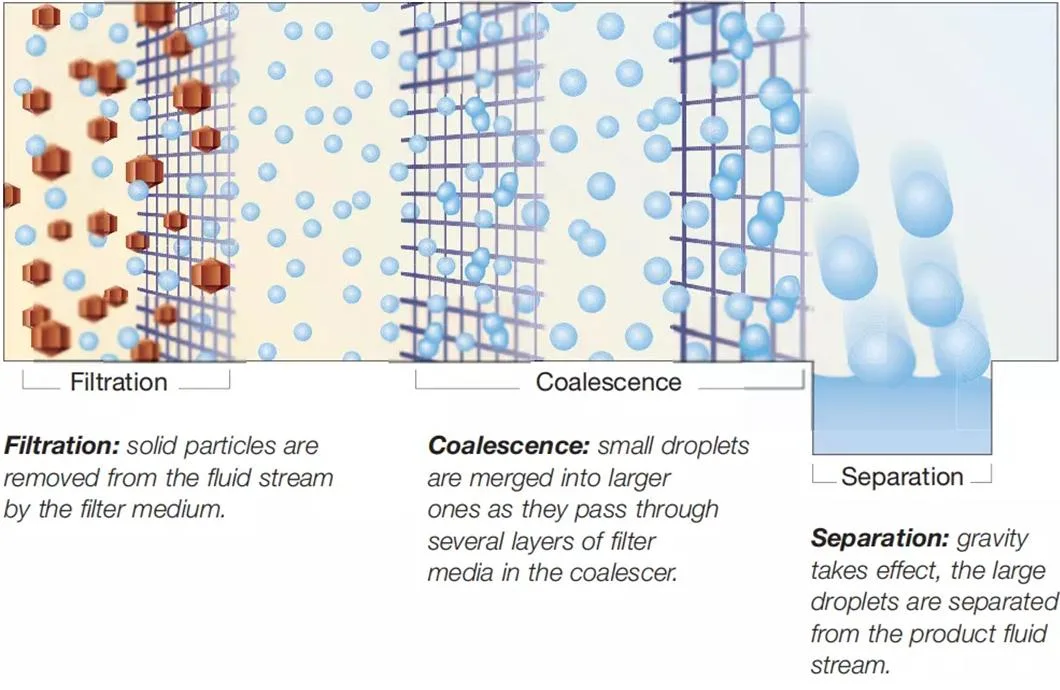

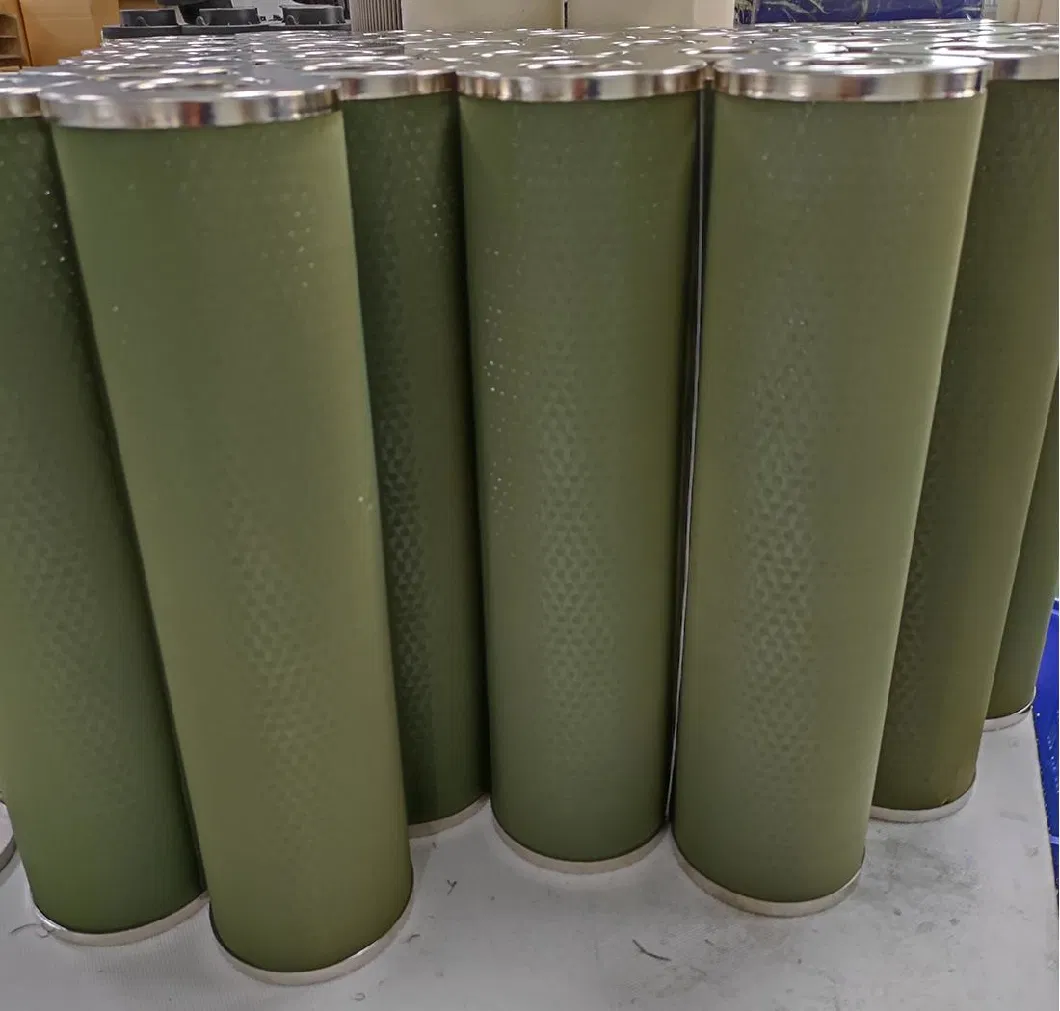

Gas efficient separation/filter element (filter element) is a separation and purification product specially designed for natural gas gathering and application. It is suitable for gas, artificial gas and other non-corrosive gases, such as nitrogen, carbon dioxide, propane, butane, gas-liquid-solid separation, gas gathering pipeline and gas transmission pipeline. Separation and purification equipment components necessary for stations, compressor stations, distribution stations, pigging stations, terminal stations and various application fields can effectively filter the dirt in pipelines and the debris peeling off the pipe wall to ensure the safe operation of gas transmission and gas equipment and meet the requirements of pipeline transportation and users for the quality of natural gas

APPLICATIONS :

Parker Velcon pleated media

cartridges are suitable for a broad

range of polar and non-polar fluids.

Recommended for applications

where the contaminant is granular

& hard, allowing maximum

utilization of the high surface area

and depth media.

SPECIFICATIONS:

y Collapse strength: 75 psi

y Operating pH range: 5 - 9

y Micron ratings: ¼ to 75

y Nominal filtration efficiency:

98%+

y Maximum operating

temperature: 250°F (121.1°C)

y Recommended changeout

differential pressure: 15 psid

for Aviation applications

y Multi-pass (Beta Ratio) data

available on request

Operating parameters:

Flow direction: from outside to inside

Maximum Operating Temperature: Polyester 240°F / 116°C

Polypropylene 180°F / 82°C

Maximum differential pressure:

3.0" O.D.: 25 psid (without core) / 1.7 bar (without core) 50 psid (with core) / 3.4 bar (with core)

4.5" O.D.: 25 psid (without core) / 1.7 bar (without core) 50 psid (with core) / 3.4 bar (with core)

5.5" O.D.: 35 psid (with core) / 2.4 bar (with core) Recommended replacement differential pressure: 12-15 psi/ 0.8-1.0 bar Maximum differential pressure limited by filter design parameters

Scope of application:

1,Aviation fuel, gasoline, paraffin, diesel.

2,Cycloethane, isopropanol, cycloethanol, cycloacetophenone, etc.

3,Turbine oil and other low viscosity hydraulic oil, lubricating oil.

4,Other hydrocarbon compounds

5,LPG, petroleum gas, petroleum tar, benzene, toluene, xylene, isopropylbenzene, polypropylene, etc.

More Model number:

FAQ:

1. Q: Are you a trading company or a manufacturer?

A: We are a professional manufacturer of all kinds of filter cartridges, housings, and filtration systems. We provide you with the total filtration solutions with our 13 years of experience in the industry.

2. Q: May I have samples?

A: Sure, of course. Sample costs can be refunded if you place formal orders in the future. But for equipment, we can't provide a sample

3. Q: Can you make customized products?

A: Yes, of course, if you can provide us with detailed specifications or drawings. Our mission is to make customers ideas on the products and provide the customer satisfied solutions.

4. Q: Can I use our own designed package?

A: Yes, size, color, logo, and packaging style all can be customized.

5. Q: What's your MOQ?

A: Normally, 6 PCS/item. Any trial order which is less than MOQ is warmly welcomed. If you have a trial order, please feel free to contact us so that we can make some shipping recommendations for you to save the cost based on the quantity you need.

6. Q: I am a small business owner, Can I buy from you?

A: Yes, you are warmly welcomed. To grow with our customers is our goal. We would like to grow with you together.

7. Q: What is your general lead time?

A: Normally 5-7 working days for off-the-shelf samples and 20-25 days for bulk production.

8. Q: How should I pay you?

A: We strongly recommend T/T, L/C, Western Union, Paypal, etc are acceptable.

Contact us:

Nora Hou

Gas efficient separation/filter element (filter element) is a separation and purification product specially designed for natural gas gathering and application. It is suitable for gas, artificial gas and other non-corrosive gases, such as nitrogen, carbon dioxide, propane, butane, gas-liquid-solid separation, gas gathering pipeline and gas transmission pipeline. Separation and purification equipment components necessary for stations, compressor stations, distribution stations, pigging stations, terminal stations and various application fields can effectively filter the dirt in pipelines and the debris peeling off the pipe wall to ensure the safe operation of gas transmission and gas equipment and meet the requirements of pipeline transportation and users for the quality of natural gas

APPLICATIONS :

Parker Velcon pleated media

cartridges are suitable for a broad

range of polar and non-polar fluids.

Recommended for applications

where the contaminant is granular

& hard, allowing maximum

utilization of the high surface area

and depth media.

SPECIFICATIONS:

y Collapse strength: 75 psi

y Operating pH range: 5 - 9

y Micron ratings: ¼ to 75

y Nominal filtration efficiency:

98%+

y Maximum operating

temperature: 250°F (121.1°C)

y Recommended changeout

differential pressure: 15 psid

for Aviation applications

y Multi-pass (Beta Ratio) data

available on request

Operating parameters:

Flow direction: from outside to inside

Maximum Operating Temperature: Polyester 240°F / 116°C

Polypropylene 180°F / 82°C

Maximum differential pressure:

3.0" O.D.: 25 psid (without core) / 1.7 bar (without core) 50 psid (with core) / 3.4 bar (with core)

4.5" O.D.: 25 psid (without core) / 1.7 bar (without core) 50 psid (with core) / 3.4 bar (with core)

5.5" O.D.: 35 psid (with core) / 2.4 bar (with core) Recommended replacement differential pressure: 12-15 psi/ 0.8-1.0 bar Maximum differential pressure limited by filter design parameters

Scope of application:

1,Aviation fuel, gasoline, paraffin, diesel.

2,Cycloethane, isopropanol, cycloethanol, cycloacetophenone, etc.

3,Turbine oil and other low viscosity hydraulic oil, lubricating oil.

4,Other hydrocarbon compounds

5,LPG, petroleum gas, petroleum tar, benzene, toluene, xylene, isopropylbenzene, polypropylene, etc.

More Model number:

| PECO 722-C-AC | PECO PRB-209-A-75A | PECO PRB-229-A-25A | PECO WC-318-C-75 | PECO FTS-318-C-50EP | PECO 1120CAC |

| PECO 1122CAC | PECO 1122CBPL | PECO 1122CRL | PECO 1130CAC | PECO 1136CAC | PECO 619CAC |

| PECO 636CACE | PECO 718CAC | PECO 719CAC | PECO 720CAC | PECO 722CAC | PECO 736CAC |

| PECO AF33605 | PECO AFVG18 | PECO AFVG36 | PECO BFGC372E | PECO BFGO72 | PECO BFGS336E |

| PECO BFGS36EA | PECO BFGS72EA | PECO C10 | PECO C12 | PECO C14 | PECO C16 |

| PECO C6112 | PECO C6142TB | PECO C6145T | PECO C6222TB | PECO C6282TB | PECO C6332TB |

| PECO C6382TB | PECO C6442TB | PECO C6562TB | PECO CF230AC10CB | PECO CIO330AC003FB | PECO CIO4361C003FV |

| PECO CS336CC | PECO FF12 | PECO FF24 | PECO FF312VITON | PECO FF324VITON | PECO FFP336 |

| PECO FFP540 | PECO FG12A | PECO FG18 | PECO FG24A | PECO FG312 | PECO FG324 |

| PECO FG336 | PECO FG36 | PECO FG372 | PECO FG524 | PECO FG536 | PECO FG572 |

| PECO FG6145 | PECO FG61810 | PECO FG62210 | PECO FG72 | ECO FGGF324 | PECO FGGF336 |

| PECO FMP436C50 | PECO FT1118B | PECO FT318C5 | PECO FT322C5 | PECO FT336C5 | PECO FT436C2 |

| PECO FT518 | PECO FT71825 | PECO FT722 | PECO FT736B | PECO FTD336 | PECO FTS312C10 |

| PECO FTS318O10 | PECO FTS330C10 | PECO FTS336C10 | PECO FTS43608 | PECO GF336 | PECO GLC1018 |

| PECO GLC818 | PECO IPC6111 | PECO IPC6141 | PECO IPC6161 | PECO IPC6221 | PECO IPC6281 |

| PECO IPC6331 | PECO IPC6381 | PECO IPC6441 | PECO KFG336 | PECO KFG372 | PECO KFG72OP |

| PECO NGGC-312 | PECO NGGC324 | PECO NGGC336 | PECO PCA3361 | PECO PCG3362 | PECO PCHG12 |

| PECO PCHG24 | PECO PCHG312 | PECO PCHG324 | PECO PCHG336 | PECO PCHG36 | PECO PCHG372 |

| PECO PCHG536 | PECO PCHG572 | PECO PCHGC312 | PECO PCHGC324 | ECO PCHGC336 | PECO PCHGC540 |

| PECO PCL25X30 | PECO PCL2875X20 | PECO PEPP631210 | PECO PEPP678110 | PECO PGHG372C | PECO PH1118B |

| PECO PH718D | PECO PM2292A | PECO PM3362ANS | PECO PM7182A | PECO PME113H | PECO PN4LA |

| PECO PP3185NS | PECO PP33610NS | PECO PP4365WS | ECO PP5095 | PECO PP5115 | PECO PP51810438 |

| PECO PP5185438 | PECO PP61410 | PECO PP6181 | PECO PP6185 | PECO PP63010 | PECO PP6365 |

| PECO PP71610 | PECO PP7165 | PECO PP718 | PECO PP722 | PECO PP736 | PECO PPCHG536 |

| PECO PPCHG572 | PECO PPFG536 | PECO PPFG572 | PECO PPL220AB20E | PECO PPL336S1B40EB | PECO PPL347S1B10E |

| PECO PPWA3365 | PECO PPWA718526875 | PECO PRE2407 | PECO PS1401IC02CB | PECO PS209AC02LB | PECO PS210AC70LB |

| PECO PSFG336 | PECO PS219AC20LB | PECO PS220AC05EP | PECO PS229AC05EB | PECO PS230AC10LB | PECO PS240AC05LB |

| PECO PS55195 | PECO PW1251O | PECO PW1541 | PECO PW1645 | PECO PW1656O16 | PECO PW1661T |

| PECO PW1044 | PECO PW1865T | PECO PW1873T | PECO PZC336CME | PECO S11 | PECO S13 |

| PECO WC718 | PECO SFX336C125 | PECO WC318C10 | PECO WC336C10 | PECO WC436C15 |

FAQ:

1. Q: Are you a trading company or a manufacturer?

A: We are a professional manufacturer of all kinds of filter cartridges, housings, and filtration systems. We provide you with the total filtration solutions with our 13 years of experience in the industry.

2. Q: May I have samples?

A: Sure, of course. Sample costs can be refunded if you place formal orders in the future. But for equipment, we can't provide a sample

3. Q: Can you make customized products?

A: Yes, of course, if you can provide us with detailed specifications or drawings. Our mission is to make customers ideas on the products and provide the customer satisfied solutions.

4. Q: Can I use our own designed package?

A: Yes, size, color, logo, and packaging style all can be customized.

5. Q: What's your MOQ?

A: Normally, 6 PCS/item. Any trial order which is less than MOQ is warmly welcomed. If you have a trial order, please feel free to contact us so that we can make some shipping recommendations for you to save the cost based on the quantity you need.

6. Q: I am a small business owner, Can I buy from you?

A: Yes, you are warmly welcomed. To grow with our customers is our goal. We would like to grow with you together.

7. Q: What is your general lead time?

A: Normally 5-7 working days for off-the-shelf samples and 20-25 days for bulk production.

8. Q: How should I pay you?

A: We strongly recommend T/T, L/C, Western Union, Paypal, etc are acceptable.

Contact us:

Nora Hou